A kind of wear-resistant ceramic preform casting device and casting process

A technology of wear-resistant ceramics and prefabricated parts, applied in the direction of manufacturing tools, supply devices, etc., can solve the problems of long production cycle, high production cost, complicated preparation process, etc., and achieve the goal of saving energy consumption, reducing equipment investment, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

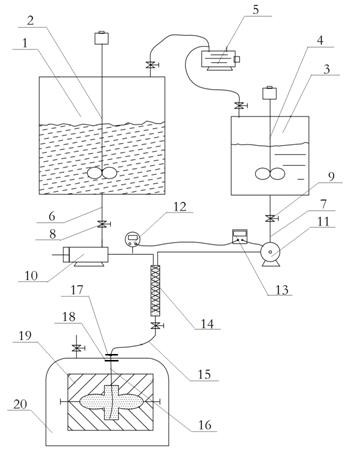

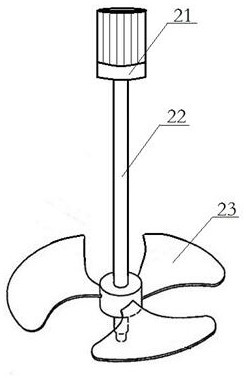

[0029] Such as figure 1 As shown, a casting device for wear-resistant ceramic preforms includes a first stirred tank 1, a second stirred tank 3, a static mixer 14, a casting mold 19 and a vacuum chamber 20, the first stirred tank 1 and the second stirred tank 3 A first stirring device 2 and a second stirring device 4 are respectively arranged inside, and the first stirring device 2 and the second stirring device 4 have the same structure. The first stirred tank 1 and the second stirred tank 3 are respectively connected with a vacuum pump 5, the first vacuum pump 5 is connected with the first stirred tank 1 and the second stirred tank 3 through an on-off valve, and the function of the vacuum pump 5 is to remove the first stirred tank 1 The air entrained in the sample injection process with the second stirred tank 3 prevents the air from being mixed into the slurry with the stirring device, entraining air bubbles inside the slurry, and the thick slurry makes the air bubbles unab...

Embodiment 2

[0037] The wear-resistant ceramic preform casting device of this embodiment is roughly the same as that of Embodiment 1, the difference is that the mold cavity of the casting mold 19 is a simple cylinder, the casting mold 19 is placed outside the vacuum chamber 20, and the static mixer 14 is passed through a hose. The cavity bottom of the casting mold 19 is connected.

[0038] A casting process for wear-resistant ceramic prefabricated parts, the prefabricated part is cylindrical in shape, comprising the following steps: (1) adding 4kg bisphenol A type epoxy resin (epoxy equivalent is 175~190), 4kg Bisphenol F type epoxy resin (epoxy equivalent is 160~175), 30kg silicon carbide powder, 5kg alumina powder; Add 8kg polyamide, 0.4kg silane coupling agent, 0.2kg DMP- 30 curing accelerator, 0.2kg fumed silica; turn on the vacuum pump 5, vacuumize the first stirred tank 1 and the second stirred tank 3 to a vacuum degree of 0.08MPa, start the first stirring device 2 and the second sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com