Preparation method of three-dimensional graphene with controllable distribution

A graphene, three-dimensional technology, applied in the field of preparation of three-dimensional graphene, can solve the problem of disordered and uncontrollable distribution of graphene, and achieve the effects of quick contact, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

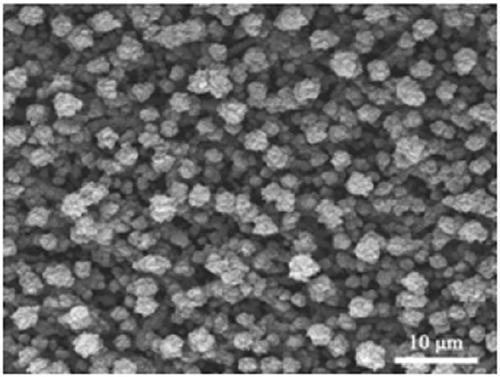

Embodiment 1

[0026] Clean silicon wafers step by step with deionized water, ethanol (99.5%), and acetone (99.9%). After drying, put it into the inductively coupled plasma multiplex system, first turn on the power supply of the coil, and adjust the power of the coil to 450 W; Sulfur gas, the flow rate is 143sccm, the gas is turned off after 9s, and octafluorocyclobutane and sulfur hexafluoride are alternately fed 3 times in this order, and the passivation and etching processes are alternately performed to obtain silicon grass. Use deionized water, ethanol (99.5%), and acetone (99.9%) to clean the silicon grass step by step. After drying, put it into the center of the heating area of the tubular plasma enhanced chemical vapor deposition equipment; adjust the distance between the RF power supply coil and the heating area to be 8cm, close the degassing valve and then vacuumize it, when the vacuum degree reaches less than 0.02 Torr, open Heat the power supply in the heating area to 900°C; fe...

Embodiment 2

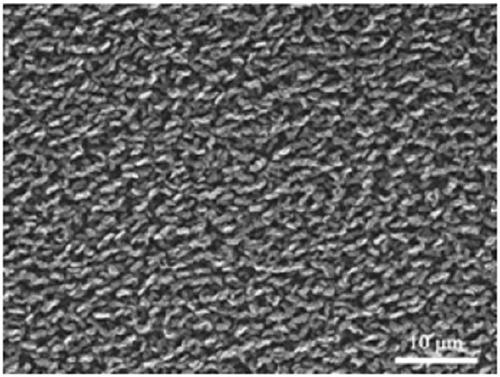

[0028] Clean silicon wafers step by step with deionized water, ethanol (99.5%), and acetone (99.9%). After drying, put it into the inductively coupled plasma multiplex system, first turn on the coil power supply, and adjust the coil power to 600 W; then pass through octafluorocyclobutane gas with a flow rate of 1 sccm, turn off the gas after 20s, and then pass through sulfur hexafluoride The gas flow rate is 1 sccm, and the gas is turned off after 20s. According to this sequence, octafluorocyclobutane and sulfur hexafluoride are alternately fed 3 times, and the passivation and etching processes are alternately performed to obtain silicon grass. Use deionized water, ethanol (99.5%), and acetone (99.9%) to clean the silicon grass step by step. After drying, put it into the center of the heating area of the tubular plasma-enhanced chemical vapor deposition equipment; adjust the distance between the RF power supply coil and the heating area to 1cm, close the degassing valve and ...

Embodiment 3

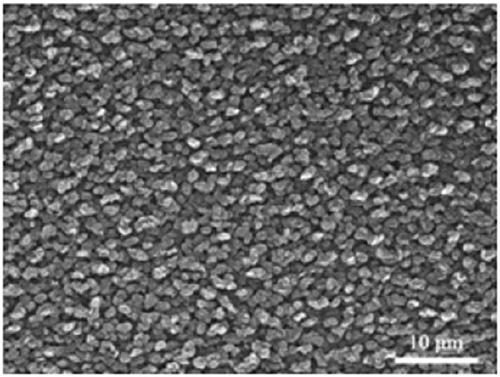

[0030] Clean silicon wafers step by step with deionized water, ethanol (99.5%), and acetone (99.9%). After drying, put it into the inductively coupled plasma multiplex system, first turn on the power supply of the coil, and adjust the coil power to 300 W; then pass in octafluorocyclobutane gas with a flow rate of 130 sccm, turn off the gas after 5s, and then pass in sulfur hexafluoride The gas flow rate is 180 sccm, and the gas is turned off after 5s. According to this sequence, octafluorocyclobutane and sulfur hexafluoride are alternately fed 3 times, and the passivation and etching processes are alternately performed to obtain silicon grass. Use deionized water, ethanol (99.5%), and acetone (99.9%) to clean the silicon grass step by step. After drying, put it into the center of the heating area of the tubular plasma-enhanced chemical vapor deposition equipment; adjust the distance between the RF power supply coil and the heating area to 50cm, close the degassing valve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com