Porous electrode and preparation and application thereof

A porous electrode and multi-level pore technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as difficult to achieve electrode performance, difficult to achieve in-depth research on electrode performance, uncontrollable porosity, pore size and channel shape, etc. Achieve the effect of reducing uncontrollable factors, increasing porosity and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

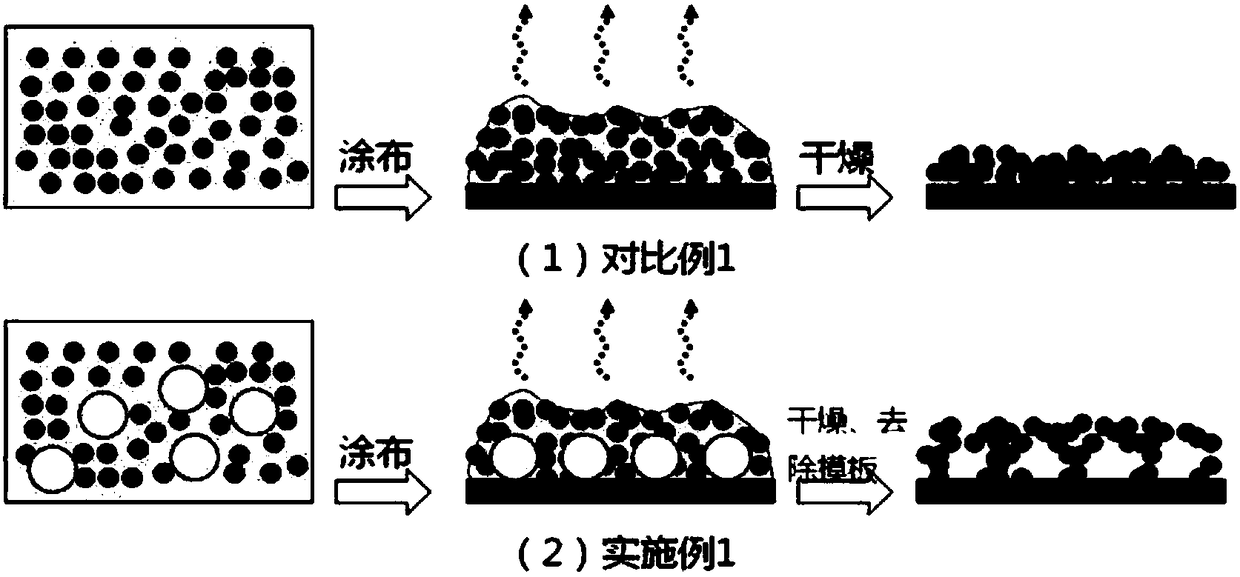

[0031] a. Preparation of electrode slurry

[0032] Take a certain mass of 60% Pt / C catalyst material, add 5 times of deionized water, 20 times of absolute ethanol, and 5% perfluorosulfonic acid polyion isopropanol solution (accounting for 20% of the mass fraction of the catalytic layer) in order. %), ultrasonically dispersed for 30min. Subsequently, polystyrene template beads with an average particle diameter of 2 μm were added, accounting for 50% of the mass fraction of the catalytic layer, and dispersed evenly by ultrasonication for 30 minutes.

[0033] b. Preparation of Porous Electrode

[0034] The above slurry is coated on the gas diffusion layer substrate by blade coating, and then dried by natural air drying.

[0035] The above dried sample was immersed in acetone solution for 2 hours to remove the template, and then rinsed with deionized water and dried to obtain the prepared porous electrode.

Embodiment 2

[0042] a. Preparation of electrode slurry

[0043] Take a certain mass of PtCo catalyst material, add 10 times of deionized water, 10 times of absolute ethanol, and 5% perfluorosulfonic acid polyion isopropanol solution (accounting for 50% of the mass fraction of the catalytic layer) in order, and ultrasonically 30 minutes to disperse evenly. Then polysilicon template beads with an average particle size of 1 μm were added, accounting for 50% of the mass fraction of the catalytic layer, and dispersed evenly by ultrasonication for 30 minutes.

[0044] b. Preparation of Porous Electrode

[0045] The above slurry is coated on the electrolyte membrane substrate by spraying, and then dried by vacuum drying or the like.

[0046] The above samples were immersed in 0.1M hydrofluoric acid solution for 5 hours to remove the template, then rinsed with deionized water and dried to obtain the prepared porous electrode.

Embodiment 3

[0048] a. Preparation of electrode slurry

[0049] Take by weighing a certain mass of 60% Pd / C catalyst material, add 10 times of deionized water, 20 times of absolute ethanol, 5% perfluorosulfonic acid polyion isopropanol solution (accounting for 40% of the mass fraction of the catalytic layer) in order. %), ultrasonically dispersed for 30min. Then, iron ferric oxide template pellets with an average particle size of 0.5 μ were added, accounting for 70% of the mass fraction of the catalytic layer, and dispersed evenly by ultrasonication for 30 minutes.

[0050] b. Preparation of Porous Electrode

[0051] The above-mentioned slurry is coated on substrates such as aluminum foil by spraying, and then dried by heating.

[0052] The above samples were immersed in 1M dilute sulfuric acid solution for 5 hours to remove the template, then rinsed with deionized water and dried to obtain the prepared porous electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com