A high-strength lime-sand brick and a production process

A production process and technology for lime-sand bricks, applied in the field of artificial stone, can solve the problems of loss of cultivated land resources, harm to human body, etc., and achieve the effect of reducing waste disposal costs, sufficient smashing effect, and reducing environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

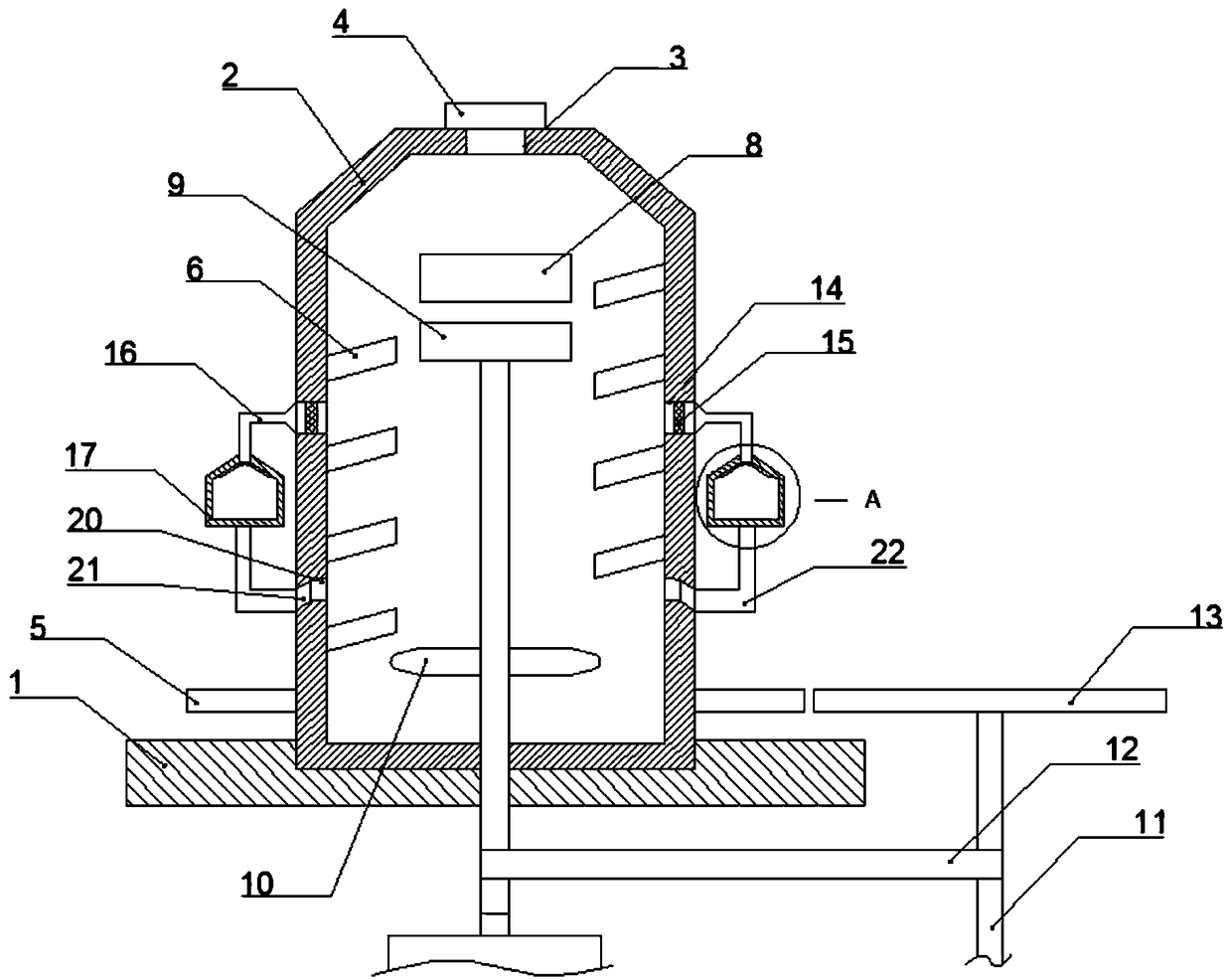

[0023] A high-strength lime-sand brick and its production process. The raw materials are hard construction and industrial waste, machine-made sand (egg machine-made sand or mountain machine-made sand), medium-coarse sand (river sand), powdery waste, and cementitious material (cement) Composition, production steps include:

[0024] Step 1: Crushing each raw material separately requires the use of a crushing device;

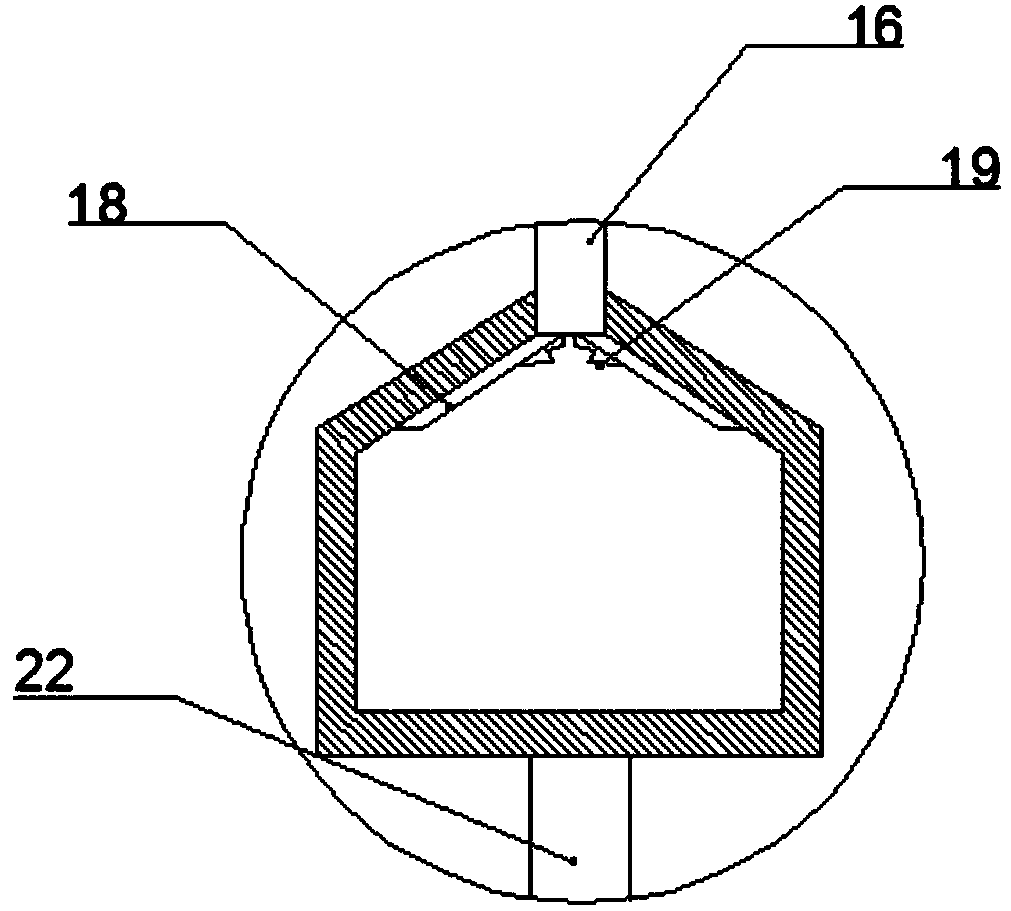

[0025] The raw materials are added into the cylindrical box 2, and the raw materials can be ground through the interaction between the rotating fixed grinding disc 7 and the linkage grinding disc 9; the raw materials after grinding are crushed by the stirring blade 10 to obtain broken particles; when the broken particles When the particle size is not greater than 0.45cm, the broken particles are collected into the collection box 17 from the discharge hole 14, the filter screen 15, and the discharge pipe 16 under the action of centrifugal force;

[0026] The rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com