Manufacturing method of burner brick for singeing machine

A production method and technology of crater bricks, applied in the field of refractory materials, can solve problems such as time-consuming and labor-intensive, short lifespan, and production stoppage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

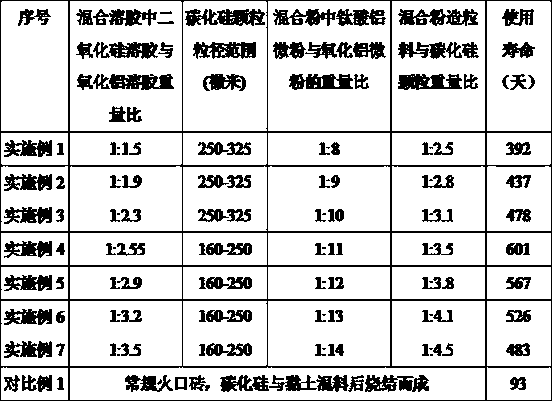

Examples

Embodiment 1

[0016] Embodiment 1: comprise the steps:

[0017] A kind of manufacture method of burner brick for singeing machine, it is characterized in that comprising the following steps:

[0018] (1) Mix the water-based silica sol and the water-based alumina sol in a weight ratio of 1:1.5 to obtain a mixed sol;

[0019] The pH of the aqueous silica sol is 2.5, and the silica content is 40%; the pH of the aqueous alumina sol is 2, and the alumina content is 40%;

[0020] (2) Put silicon carbide particles with a particle size ranging from 250 to 325 microns into the mixed sol prepared in step (1), soak for 0.5 hours, filter, dry at 150°C, and repeat this process twice to obtain mixed Sol-coated silicon carbide particles;

[0021] (3) Add 8% by weight of PVA glue and 4% by weight of mixed sol to the mixed powder of aluminum titanate and alumina, compact it and crush it, and pass through a 10-mesh sieve to obtain the mixed powder for granulation material;

[0022] The mixing process of ...

Embodiment 2

[0025] Embodiment 2: comprise the steps:

[0026] A kind of manufacture method of burner brick for singeing machine, it is characterized in that comprising the following steps:

[0027] (1) Mix the water-based silica sol and the water-based alumina sol in a weight ratio of 1:1.9 to obtain a mixed sol;

[0028] The pH of the aqueous silica sol is 2.5, and the silica content is 40%; the pH of the aqueous alumina sol is 2, and the alumina content is 40%;

[0029] (2) Put silicon carbide particles with a particle size ranging from 250 to 325 microns into the mixed sol prepared in step (1), soak for 0.5 hours, filter, dry at 150°C, and repeat this process twice to obtain mixed Sol-coated silicon carbide particles;

[0030] (3) Add 8% by weight of PVA glue and 4% by weight of mixed sol to the mixed powder of aluminum titanate and alumina, compact it and crush it, and pass through a 10-mesh sieve to obtain the mixed powder for granulation material;

[0031] The mixing process of ...

Embodiment 3

[0034] Embodiment 3: comprise the steps:

[0035] A kind of manufacture method of burner brick for singeing machine, it is characterized in that comprising the following steps:

[0036] (1) Mix the water-based silica sol and the water-based alumina sol in a weight ratio of 1:2.3 to obtain a mixed sol;

[0037] The pH of the aqueous silica sol is 2.5, and the silica content is 40%; the pH of the aqueous alumina sol is 2, and the alumina content is 40%;

[0038] (2) Put silicon carbide particles with a particle size ranging from 250 to 325 microns into the mixed sol prepared in step (1), soak for 0.5 hours, filter, dry at 150°C, and repeat this process twice to obtain mixed Sol-coated silicon carbide particles;

[0039] (3) Add 8% by weight of PVA glue and 4% by weight of mixed sol to the mixed powder of aluminum titanate and alumina, compact it and crush it, and pass through a 10-mesh sieve to obtain the mixed powder for granulation material;

[0040] The mixing process of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com