Positive-pressure coal firing/biomass gasification coupled power generation system as well as method for electric energy conversion

A technology of power generation system and biomass, which is applied in gasification process, manufacture of combustible gas, chemical industry, etc., can solve the problems of tar contamination of inner wall and heating surface of conveying pipeline, instability of feeding system and influence of heat exchange, etc. Save equipment investment costs and maintenance costs, not easy to block material phenomenon, the effect of stable feeding system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

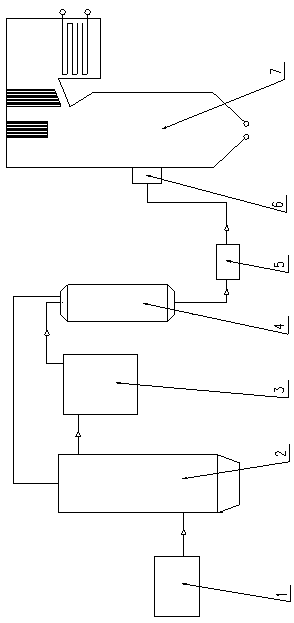

[0018] A positive pressure coal-fired coupled biomass gasification power generation system, which consists of: a feeding device 1, the feeding device is connected to the gasifier system 2 through pipelines, and the gasifier system is respectively connected to the ash The slag processing device 3 and the gas cooling device 4 are connected through a pipeline, the ash processing device is connected with the gas cooling device through a pipeline, and the gas cooling device is connected with the gas delivery device 5 through a pipeline, so The gas delivery device is connected to the gas combustion device 6 through pipelines, and the gas combustion device is connected to the coal-fired boiler 7 .

Embodiment 2

[0020] According to the positive pressure coal-fired coupled biomass gasification power generation system described in Example 1, a blower is installed inside the gasifier system, and an inert gas is installed inside the gasifier system and the gas delivery device The purge point and the release point, the gas flow rate of the gas delivery device is 15~30m / s, the gas cooling device is surrounded by a gas-heat transfer oil heat exchanger outer wall, and the gas-heat transfer oil heat exchanger outer wall The temperature is 350~450°C.

Embodiment 3

[0022] A method for converting electric energy using the positive pressure coal-fired coupled biomass gasification power generation system described in Embodiment 1 or 2, the method includes the following steps: first, setting the partial operating pressure of the feeding system connected to the gasifier system It is higher than the feed port of the gasification furnace, and then the feed system transports the biomass fuel to the gasification furnace system, the gasification furnace system produces ash and gas, the ash is sent to the ash processing device, and the gas is sent to the gas cooling device, The gas cooling device adopts the indirect heat exchange mode of "gas-heat transfer oil-cooling water". After the gas is cooled by the gas cooling device, it is sent to the gas combustion device through the gas delivery device. The furnace system, gas delivery device and gas combustion device are all operated under positive pressure;

[0023] The gas delivery pressure is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com