Processing method for target materials to be processed

A processing method and target technology, applied in the field of semiconductor sputtering target manufacturing, can solve the problems of low recovery rate of waste targets and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

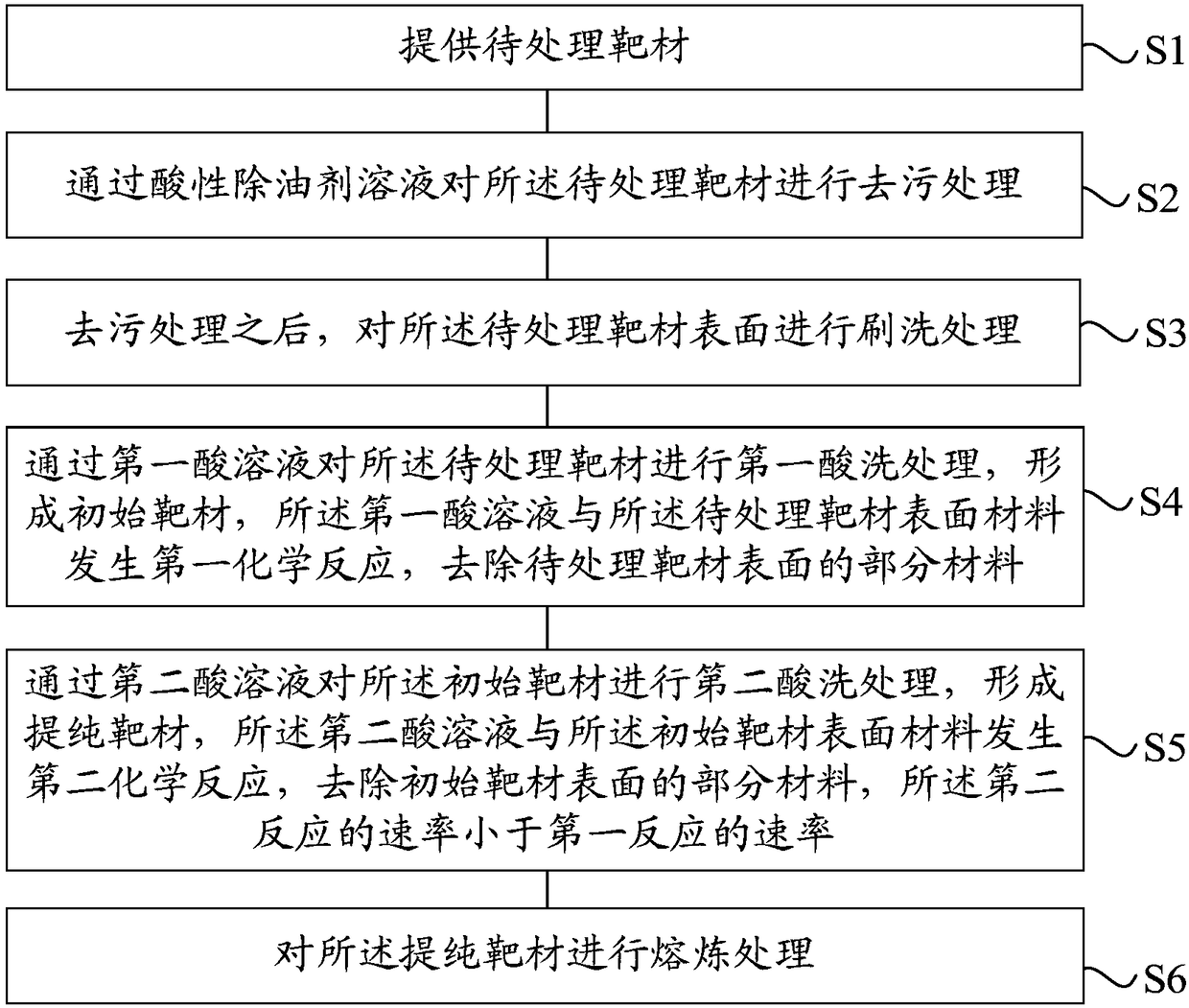

Method used

Image

Examples

Embodiment Construction

[0035] The recycling rate of the target to be treated in the prior art is very low.

[0036] Combined with the treatment methods of waste titanium targets, the reasons for the low recycling rate of targets to be treated are analyzed:

[0037] There are two main ways to treat waste titanium targets: one is to be sold as waste titanium at a low price; the other is to cut some titanium plates or particles from waste titanium targets by machining.

[0038] The first treatment method does not reuse the titanium target, resulting in waste of titanium material. Although the second treatment method allows the waste titanium target to be easily recycled, the surface of the titanium target becomes rough due to the bombardment of high-energy ions after sputtering, and has a strong adsorption effect on impurities. In addition, due to the high surface temperature of the waste titanium target formed after the titanium target is sputtered, it is easy to react with external impurities, resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com