Fluorescent nanofiber film for detecting tnt and its preparation method and application

A nanofiber and film technology, which is applied in the detection of TNT fluorescent nanofiber film and its preparation and application, can solve the problems of low response efficiency and no detection of strong explosive TNT, and achieves fine diameter, wide application and high specific surface area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

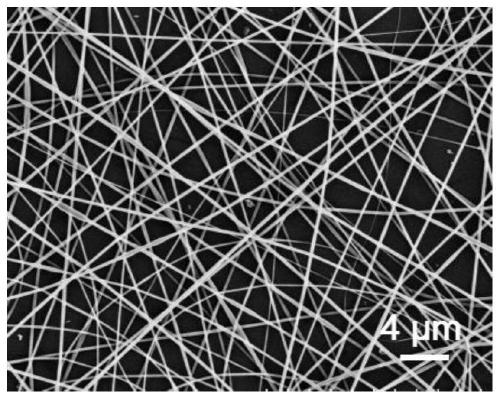

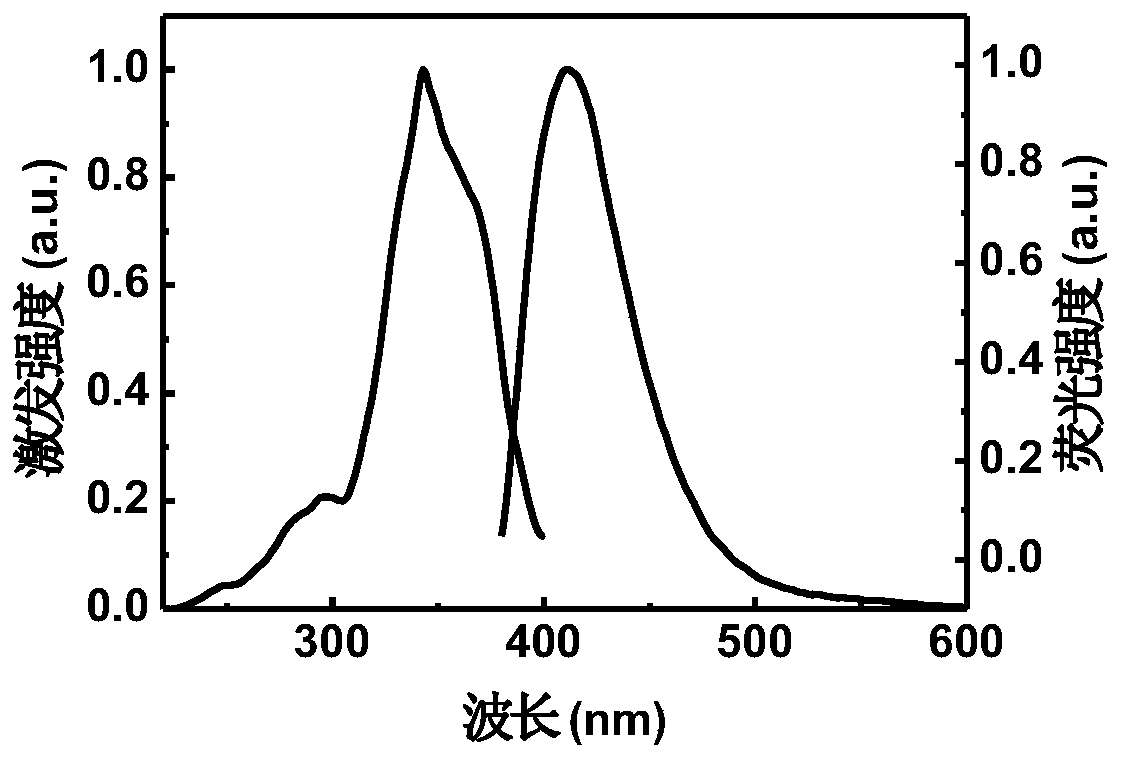

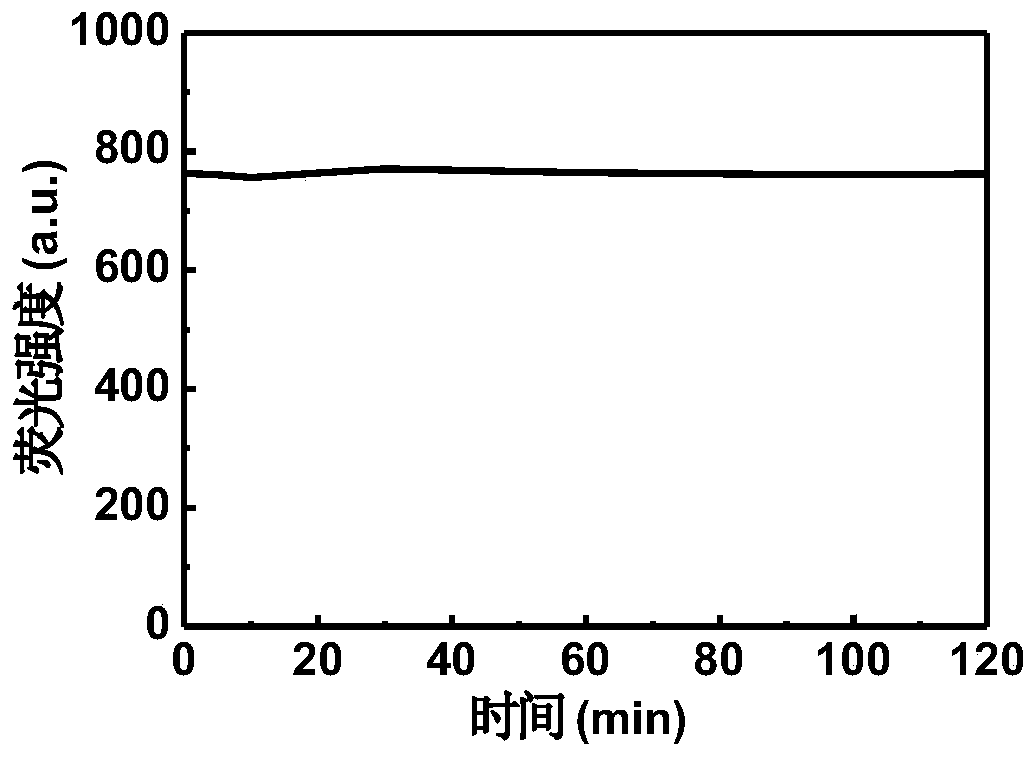

[0024] First, 9 mg of PyCz fluorescent probe and 455 mg of PNIPAM polymer were dissolved in 4 mL of DMF solution, and vigorously stirred at 10° C. to form a 2 wt% transparent and uniform electrospinning solution. The electrospinning polymer solution was put into a 2mL disposable syringe, and a 10kV DC voltage was applied to a stainless steel needle with an inner diameter of 0.6mm through electrospinning technology. The polymer solution was injected at a flow rate of 0.003mm / s, and the receiver The distance to the needle is 15cm, the air humidity is 30%HR, and the temperature is 10℃. Electrospinning is carried out. The fiber is deposited on a quartz sheet of 5mm × 25mm × 1mm on aluminum foil to obtain a PNIPAM / PyCz nanofiber film. 5min.

[0025] The experimental procedure for detecting explosive vapor is as follows: firstly take 15mg of 2,4,6-trinitrotoluene, urea, naphthalene, and sodium nitrite into a cylindrical (diameter φ5mm×height 3mm) aluminum container and use plastic wrap...

Embodiment 2

[0033] First, 2.5 mg of PyCz fluorescent probe and 240 mg of PNIPAM polymer were dissolved in 2 mL of DMF solution, and vigorously stirred at 10° C. to form a 1 wt% transparent and uniform electrospinning solution. The electrospinning polymer solution was put into a 2mL disposable syringe, and a 10kV DC voltage was applied to a stainless steel needle with an inner diameter of 0.6mm through electrospinning technology. The polymer solution was injected at a flow rate of 0.003mm / s, and the receiver The distance to the needle is 15cm, the air humidity is 30%HR, and the temperature is 10℃. Electrospinning is carried out, and the fiber is deposited on a 5mm×25mm×1mm quartz plate on the aluminum foil to obtain PNIPAM / PyCz nanofibers. The time is 5min.

[0034] The experimental procedure for detecting explosive vapor is as follows: firstly take 15mg of 2,4,6-trinitrotoluene, urea, naphthalene, and sodium nitrite into a cylindrical (diameter φ5mm×height 3mm) aluminum container and use pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com