Method for improving dyeing efficiency of fishing net

A fishing net and high efficiency technology, applied in the field of improving fishing net dyeing efficiency, can solve the problems of affecting the use effect of fishing nets, slow dyeing speed, weak staining, etc., to improve fading fastness, not easy to fade, improve staining fastness and Effect of Dyeing Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

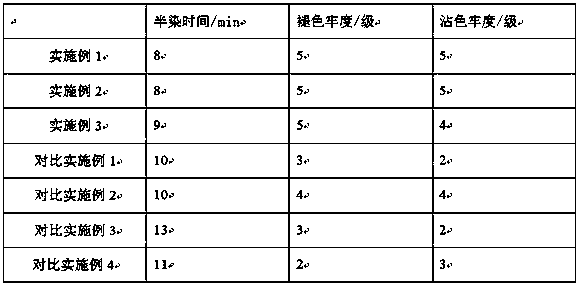

Examples

Embodiment 1

[0018] A method for improving fishing net dyeing efficiency is characterized in that it comprises the following steps:

[0019] (1) Put the fishing net into the composite dyeing solution, raise the temperature to 40°C, stir at 300 rpm for 20 minutes, then take it out, drain off the excess composite dyeing solution, and transfer the obtained fishing net into the reaction kettle;

[0020] (2) Put steam into the reaction kettle, the steam pressure is 200KPa, the temperature is 120°C, keep it for 30min, then discharge the steam, and evacuate to -0.08MPa, cool down to -10°C, and treat for 1h;

[0021] (3) Repeat the operation of step (2) 3 times, and finally place it at 60°C for 5 hours, wash it with clean water for 3 times, spray it with 3% chitosan solution, and put the fishing net at 30°C after spraying evenly Just tumble dry.

[0022] Further, the composite dyeing liquid in step (1) is made of cationic dyes, castor oil, nano diatomaceous earth, polyvinyl alcohol, calcium ligno...

Embodiment 2

[0029] A method for improving fishing net dyeing efficiency is characterized in that it comprises the following steps:

[0030] (1) Put the fishing net into the composite dyeing solution, raise the temperature to 45°C, stir at 350 rpm for 25 minutes, then take it out, drain off the excess composite dyeing solution, and transfer the obtained fishing net into the reaction kettle;

[0031] (2) Put steam into the reaction kettle, the steam pressure is 220KPa, the temperature is 123°C, keep it for 40min, then discharge the steam, and evacuate to -0.09MPa, cool down to -13°C, and treat for 2h;

[0032] (3) Repeat the operation of step (2) 4 times, and finally place it at 65°C for 8 hours, wash it with water for 4 times, spray it with 5% chitosan solution, and put the fishing net at 35°C after spraying evenly Just tumble dry.

[0033] Further, the composite dyeing liquid in step (1) is made of cationic dyes, castor oil, nano diatomaceous earth, polyvinyl alcohol, calcium lignosulfon...

Embodiment 3

[0040] A method for improving fishing net dyeing efficiency is characterized in that it comprises the following steps:

[0041] (1) Put the fishing net into the composite dyeing solution, raise the temperature to 50°C, stir at 400rpm for 30 minutes, then take it out, drain off the excess composite dyeing solution, and transfer the obtained fishing net into the reaction kettle;

[0042] (2) Put steam into the reaction kettle, the steam pressure is 250KPa, the temperature is 125°C, keep for 60min, then discharge the steam, and vacuumize to -0.1MPa, cool down to -15°C, and treat for 2h;

[0043] (3) Repeat the operation of step (2) 4 times, and finally place it at 70°C for 10 hours, wash it with water for 5 times, spray it with 6% chitosan solution, and put the fishing net at 40°C after spraying evenly Just tumble dry.

[0044] Further, the composite dyeing liquid in step (1) is made of cationic dyes, castor oil, nano diatomaceous earth, polyvinyl alcohol, calcium lignosulfonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com