Solenoid valve drive device and drive method

A solenoid valve drive, solenoid valve technology, applied in the direction of the valve device, valve operation/release device, valve details, etc., can solve the problems of slow response time of relays, increase product energy consumption, unfavorable equipment protection, etc., to achieve stable protection and operation Performance and operational safety, low manufacturing cost and maintenance cost, high practical value and promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

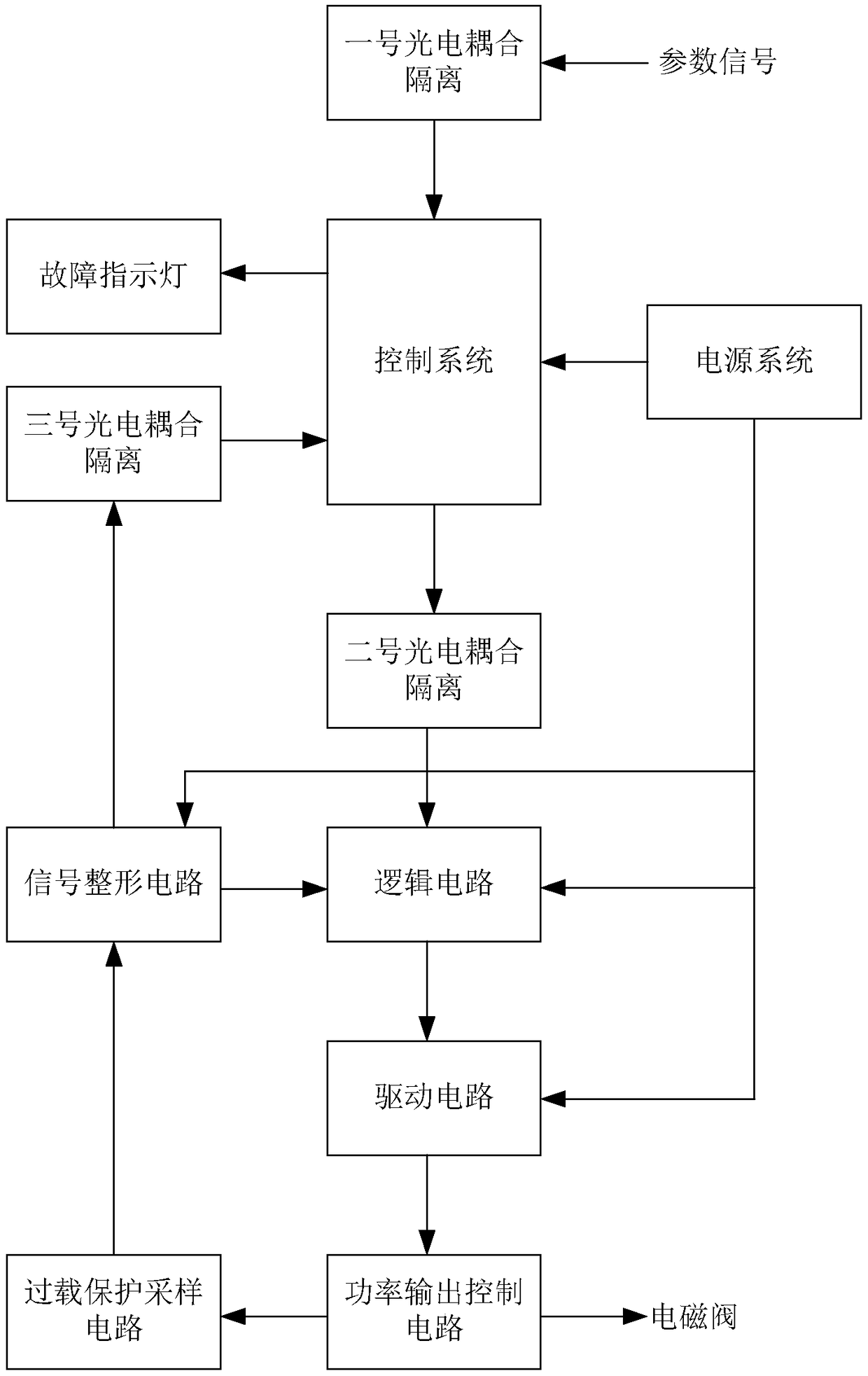

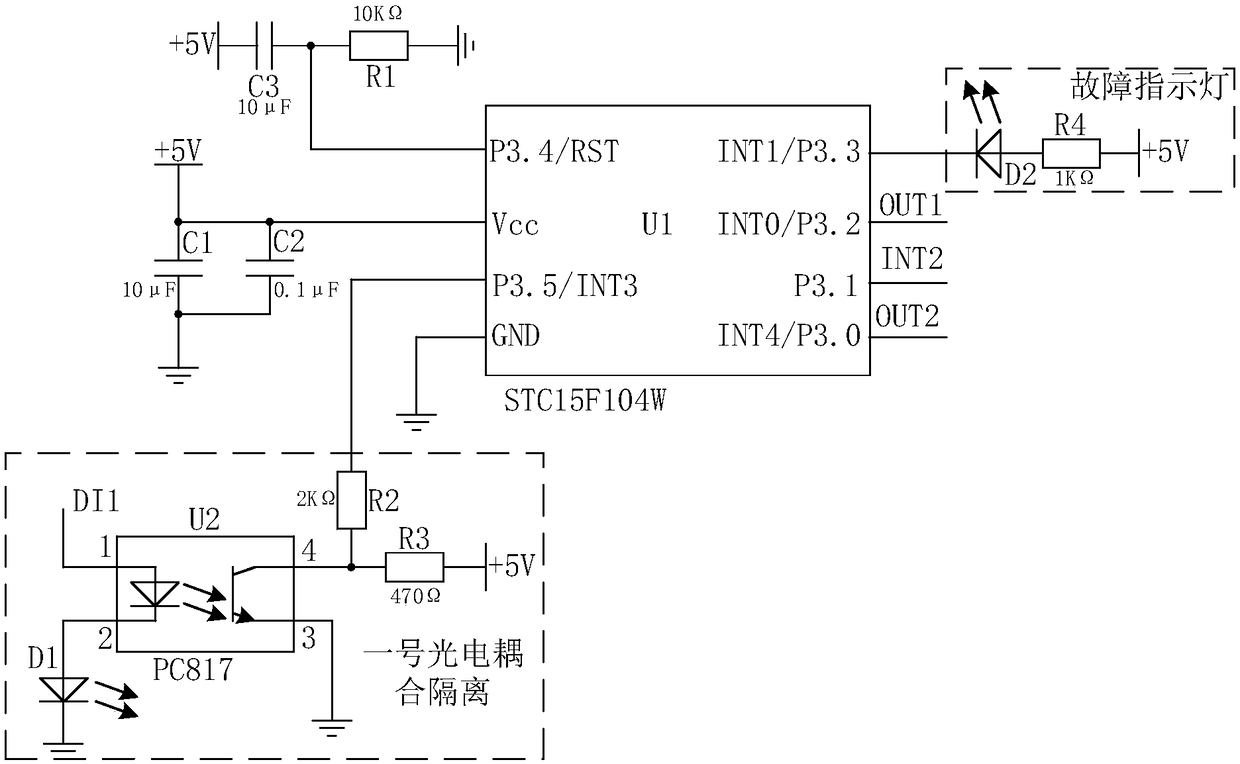

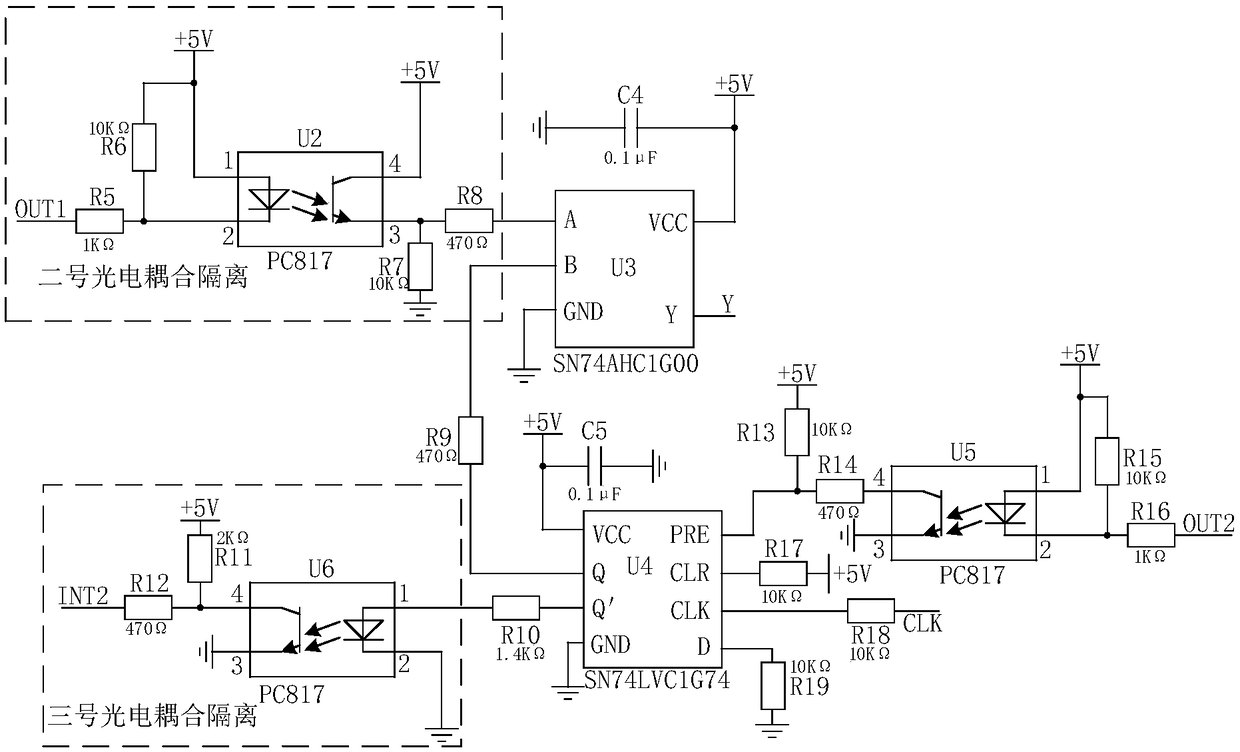

[0043] Such as figure 1 As shown, a solenoid valve drive device includes a control system, a power supply system, a logic circuit, a drive circuit, a power output control circuit, an overload protection sampling circuit and a signal shaping circuit.

[0044] The control system can accept parameter signals, the logic circuit is connected to the control system, the drive circuit is connected to the logic circuit, the power output control circuit is connected to the drive circuit and used to control the solenoid valve, and the overload protection sampling circuit is connected to the power output control circuit. Connection, the signal shaping circuit is connected with the overload protection sampling circuit, and the power supply system provides full power supply to each circuit in the whole device, and the power supply voltage is DC+5V or DC+8V or AC220V.

[0045] The specific circuit for the power system to convert 220V AC power into +5V or +8V DC power is a conventional techni...

Embodiment 2

[0088] This embodiment discloses a method for driving a solenoid valve, which includes the following operating steps:

[0089] (1) Connect the solenoid valve driving device to the solenoid valve through the power output control circuit;

[0090] (2) Through the computer, the parameter signal is imported into the single-chip microcomputer chip of the control system in real time through No. 1 photoelectric coupling isolation;

[0091] (3) The control system generates a PWM drive control signal according to the imported parameter signal, and outputs it through the No. 2 photoelectric coupling isolation;

[0092] The initial pulse width of the generated PWM drive control signal is relatively wide, so that the solenoid valve can have enough driving force to pull in. After the solenoid valve pulls in, the PWM drive control signal with a low pulse width is periodically output to So that the solenoid valve can maintain the pull-in state;

[0093] Such as Figure 8 shown, t 1 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com