A large mode field double-clad ytterbium-doped fiber

A technology of ytterbium-doped fiber and double cladding, applied in cladding fiber, multi-layer core/cladding fiber, optics, etc., to increase the manufacturing cost and difficulty, improve the doping distribution, and ensure the fundamental mode field area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

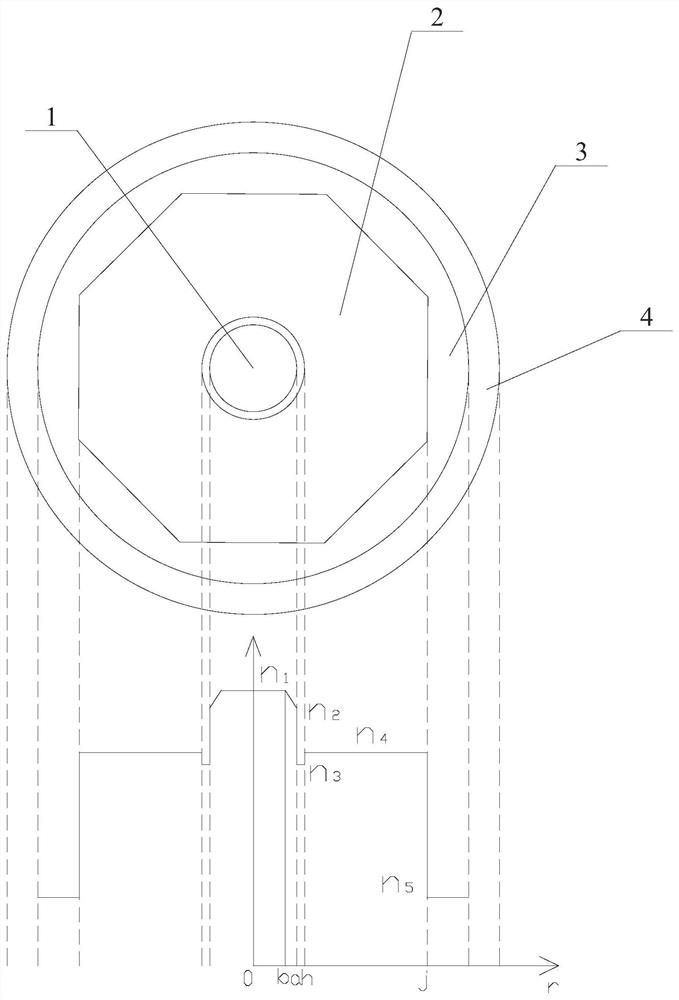

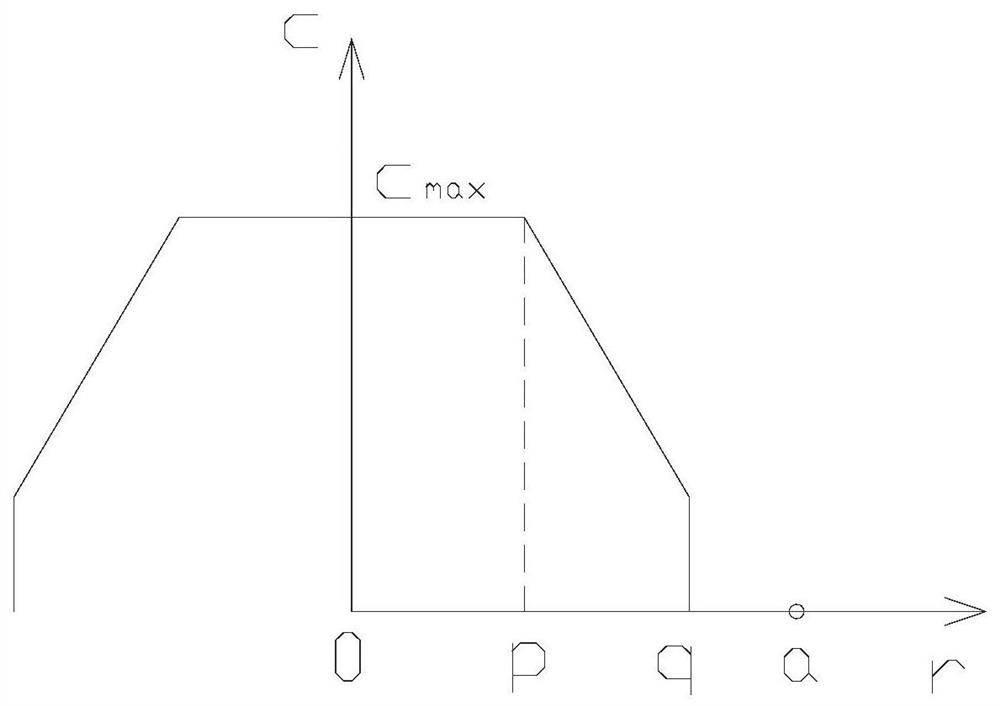

[0055] The ytterbium doping concentration of the core 1 is a trapezoidal distribution, the radius q of the ytterbium doping region is 11.9 μm, the radius p of the region with the highest ytterbium doping concentration is 5.8 μm, and the highest ytterbium doping concentration C max is 1200ppm, and the concentration of ytterbium in the outermost part of the doped region is 400ppm, so the core 1 adopts a triangular and step-shaped composite refractive index design, and the refractive index measured by a laser with a wavelength of 632.8nm is n 1 = 1.45891, n 2 = 1.45840, n 3 = 1.45719, n 4 =1.45762, and the refractive index n 1 The radius of the region b=9.0μm, the outer diameter of the refractive index concave region h=17.0μm, the measured output mode field diameter is 20.7μm, and the beam quality factor M 2 = 1.32.

Embodiment 2

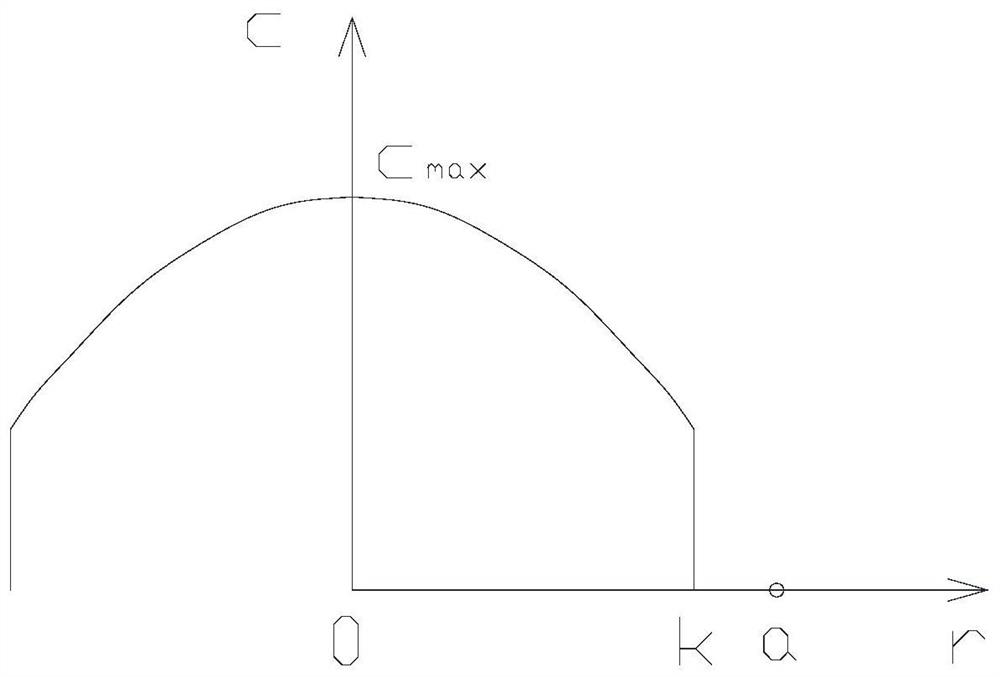

[0057] The ytterbium doping concentration of core 1 is a parabola-like distribution, the radius k of the doping region is 12.0 μm, and the highest ytterbium doping concentration C max is 1200ppm, the concentration of ytterbium in the outermost part of the doped region is 480ppm, and the coefficient t=5ppm·μm -2 , the refractive index design of the core 1 is the same as that of the first embodiment, and the measured output mode field diameter is 21.0 μm, and the beam quality factor M 2 = 1.41.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com