A decoupling control method for a suspension system of a four-degree-of-freedom magnetic levitation motor

A decoupling control and decoupling controller technology, applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve the problems of slow convergence speed, good generalization performance, difficult to determine the accuracy of the magnetic levitation control system model, etc. problem, to achieve the effect of improving dynamic performance, simplifying control steps, and getting rid of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

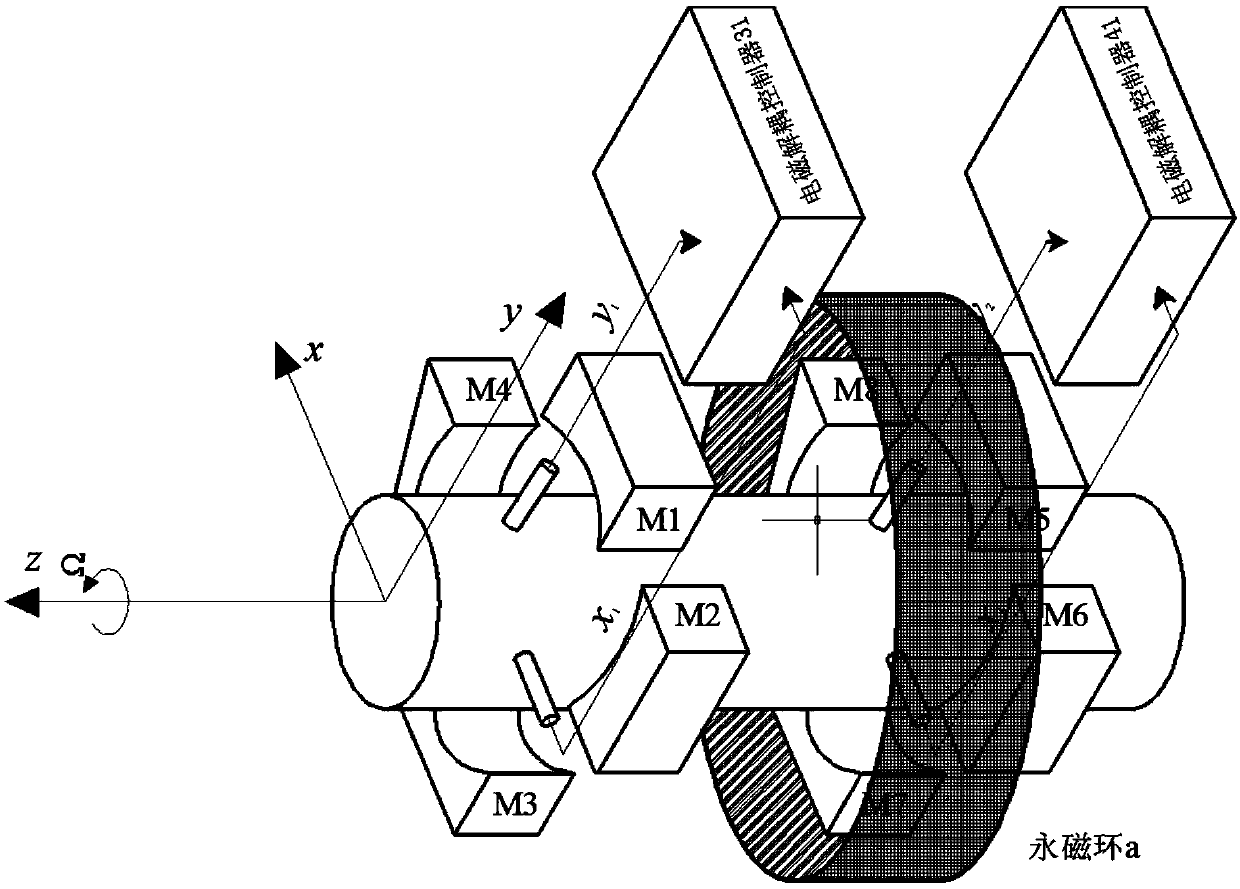

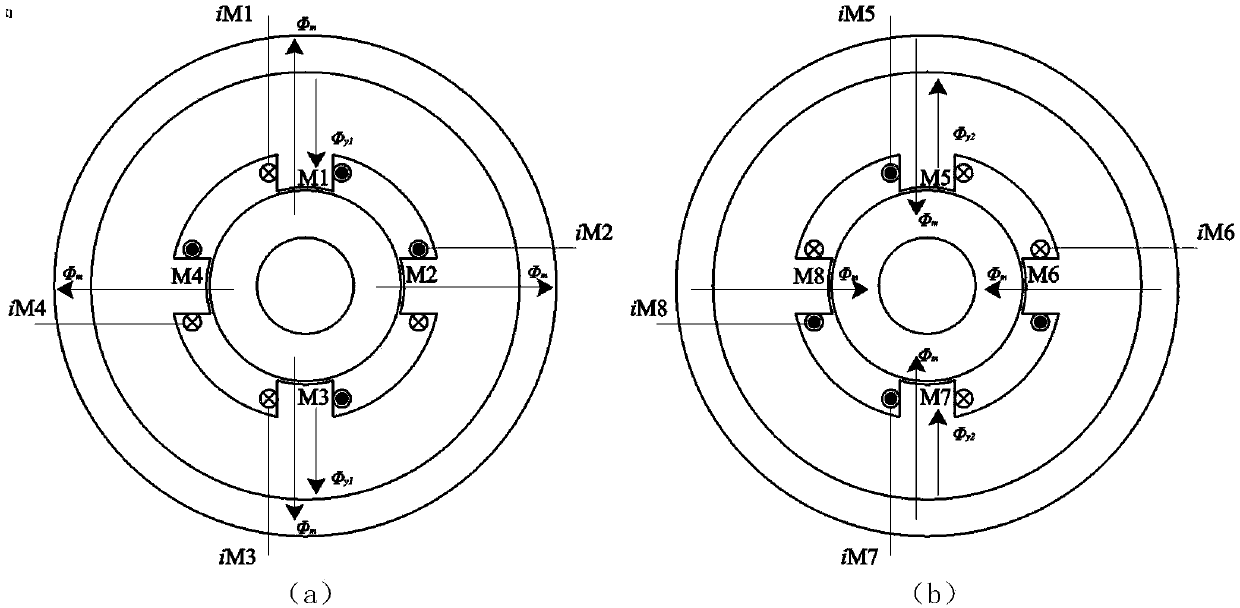

[0025] Such as figure 1 and 2 As shown, the levitation system of the four-degree-of-freedom magnetic levitation motor consists of a permanent magnet ring a, a rotor, and 8 magnetic poles M1-M8 on the stator, and 8 control coils iM are wound on the magnetic poles respectively. 1 ~iM 8 To form, the magnetic pole coils on the same degree of freedom are connected in series, controlled by the same direct current, that is, iM 1 , iM 3 in series, iM 2, iM 4 in series, iM 5 , iM 7 Tandem and iM 6 , iM 8 connected in series, direct current is passed through the coil respectively to excite i y1 i x1 i y2 i x2 , the center of the rotor is balanced at the geometric center of the stator.

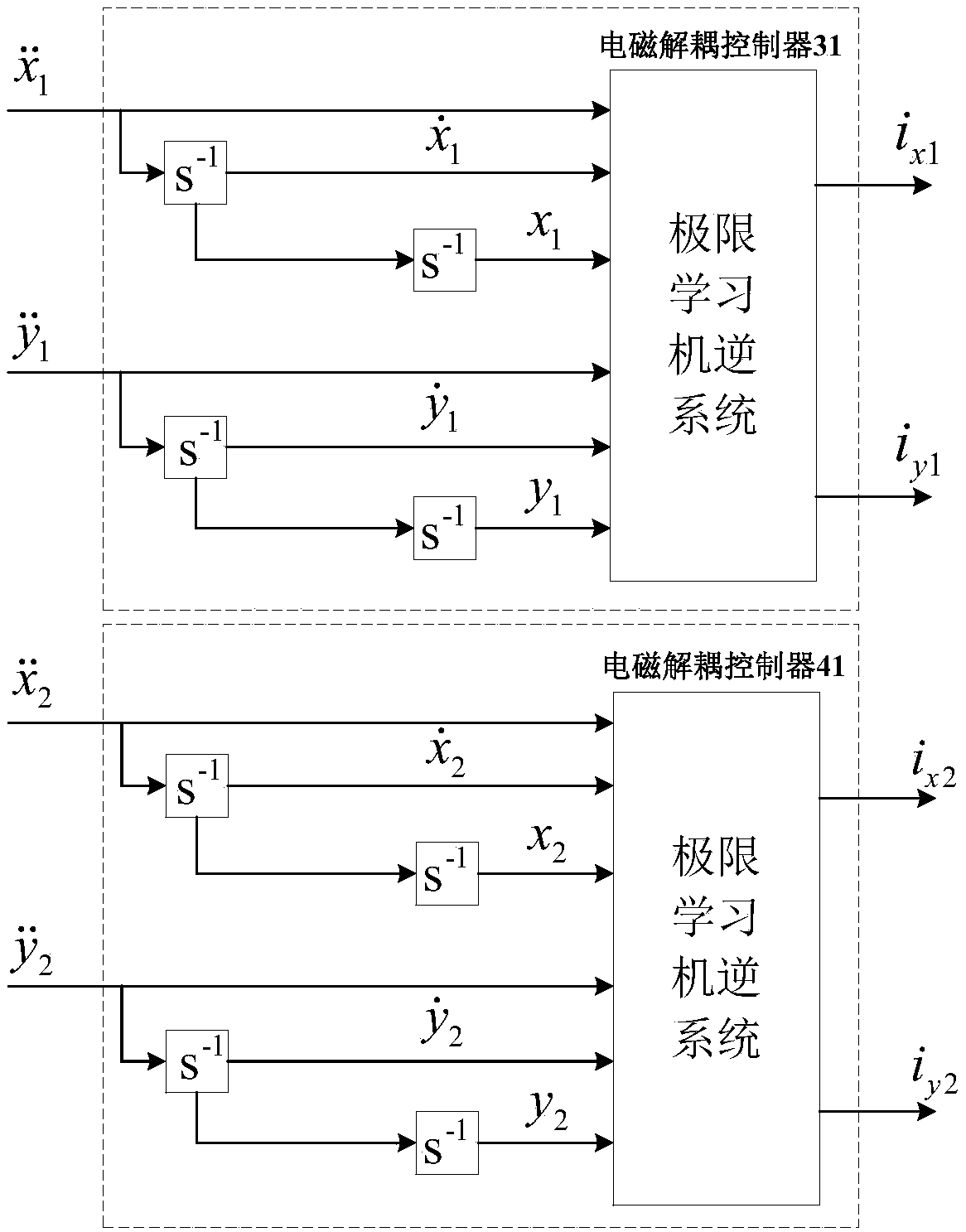

[0026] Such as image 3 As shown, the electromagnetic decoupling controllers 31, 41 respectively use the second derivative of the displacement deviation and Is the input, the output controls the DC excitation current i of the bearing movement x1 i y1 with i x2 i y2 , the rotor of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com