Submicron fragrance capsule capable of emulsification, and preparation method and application thereof

A technology with fine submicron and emulsifying function, which is applied in the direction of medical preparations containing active ingredients, cosmetic preparations, skin care preparations, etc., can solve problems such as restrictions on wide application, and achieve avoidance of skin irritation, mild reaction conditions, The effect of improving the fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

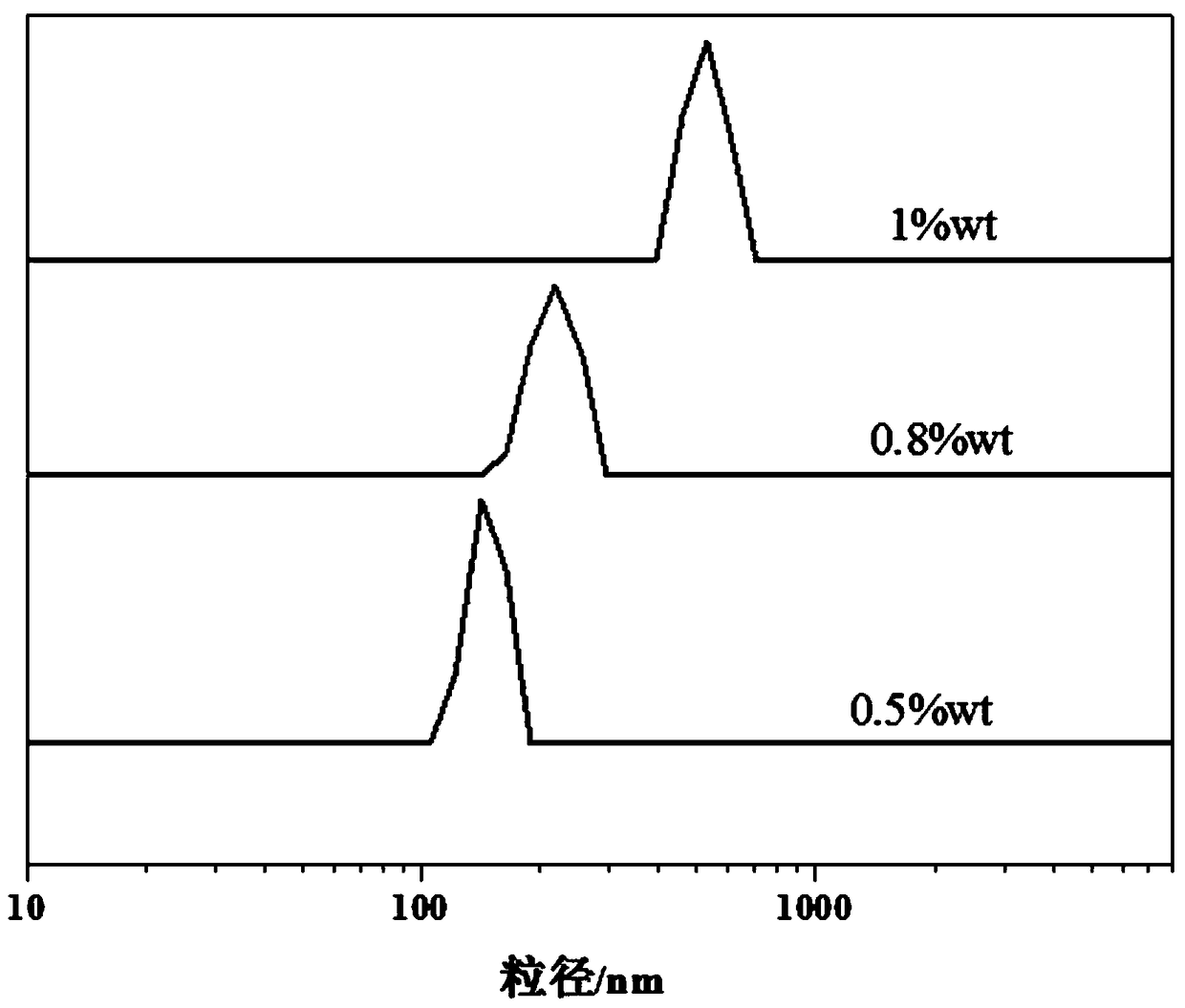

[0035] A fragrance submicron capsule with emulsification function is made of the following raw materials: 0.5 parts by weight of octyl alginate, 0.25 parts by weight of essence, and 0.5 parts by weight of calcium monohydrogen phosphate.

[0036] Concrete preparation method comprises the following steps:

[0037] (1) Add octyl alginate powder into deionized water, stir at room temperature until completely dissolved, and prepare a octyl alginate solution with a concentration of 0.5% by mass.

[0038] (2) Slowly add the essence dropwise into the alginic acid octylamide solution, stir and mix evenly at a constant temperature of 20°C, and then perform shear emulsification at 15000rpm for 13min to form a primary emulsion. (3) Pass the emulsion through a jet micromixer to obtain an emulsion with a smaller particle size and uniform distribution, receive it in the calcium monohydrogen phosphate suspension under magnetic stirring, and continue magnetic stirring for 3 hours at room tempe...

Embodiment 2

[0041] A fragrance submicron capsule with emulsifying function is made of the following raw materials: 0.8 parts by mass of octyl alginate, 0.4 parts by mass of essence, and 0.8 parts by mass of calcium monohydrogen phosphate.

[0042] Concrete preparation method comprises the following steps:

[0043] (1) Add octyl alginate powder into deionized water, stir at room temperature until completely dissolved, and prepare a octyl alginate solution with a concentration of 0.8% by mass.

[0044] (2) The essence was slowly added dropwise to the alginic acid octylamide solution, stirred and mixed evenly at a constant temperature of 20°C, and shear emulsified at 12000rpm for 10min to form a primary emulsion.

[0045] (3) Pass the emulsion through a jet micromixer to obtain an emulsion with smaller particle size and uniform distribution, receive it in the calcium monohydrogen phosphate suspension under magnetic stirring, and continue magnetic stirring for 4 hours at room temperature to c...

Embodiment 3

[0048] A fragrance submicron capsule with an emulsifying function is made of the following raw materials: 1 part by mass of octyl alginate, 0.5 part by mass of essence, and 1 part by mass of calcium monohydrogen phosphate.

[0049] Concrete preparation method comprises the following steps:

[0050](1) Add octyl alginate powder into deionized water, stir at room temperature until completely dissolved, and prepare a octyl alginate solution with a concentration of 1% by mass.

[0051] (2) The essence was slowly added dropwise to the alginic acid octylamide solution, stirred and mixed evenly at a constant temperature of 20°C, and shear emulsified at 10,000rpm for 5min to form a primary emulsion.

[0052] (3) Pass the emulsion through a jet micromixer to obtain an emulsion with smaller particle size and uniform distribution, receive it in the calcium monohydrogen phosphate suspension under magnetic stirring, and continue magnetic stirring for 5 hours at room temperature to carry ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com