Soot blowing system and method for SCR (Selective Catalytic Reduction) reactor

A technology of SCR reactor and soot blowing system, which is applied in the field of soot blowing and SCR reactor soot blowing system, which can solve the problems of increasing the difficulty of operation and maintenance of SCR reactor, reducing the reliability of SCR reactor, and complicated purge pipeline , to achieve the effect of not easy to cause failure, simple structure and good purging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

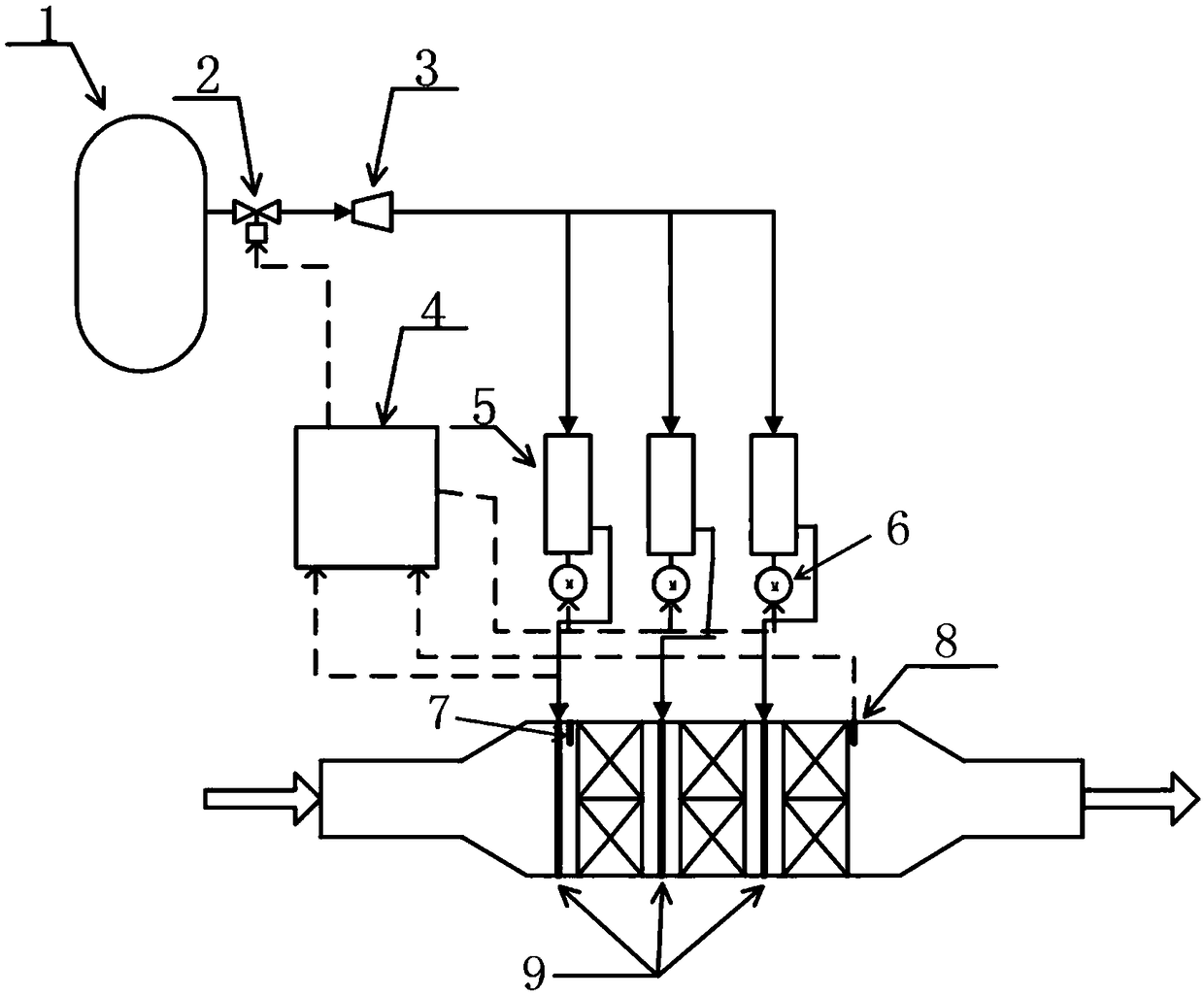

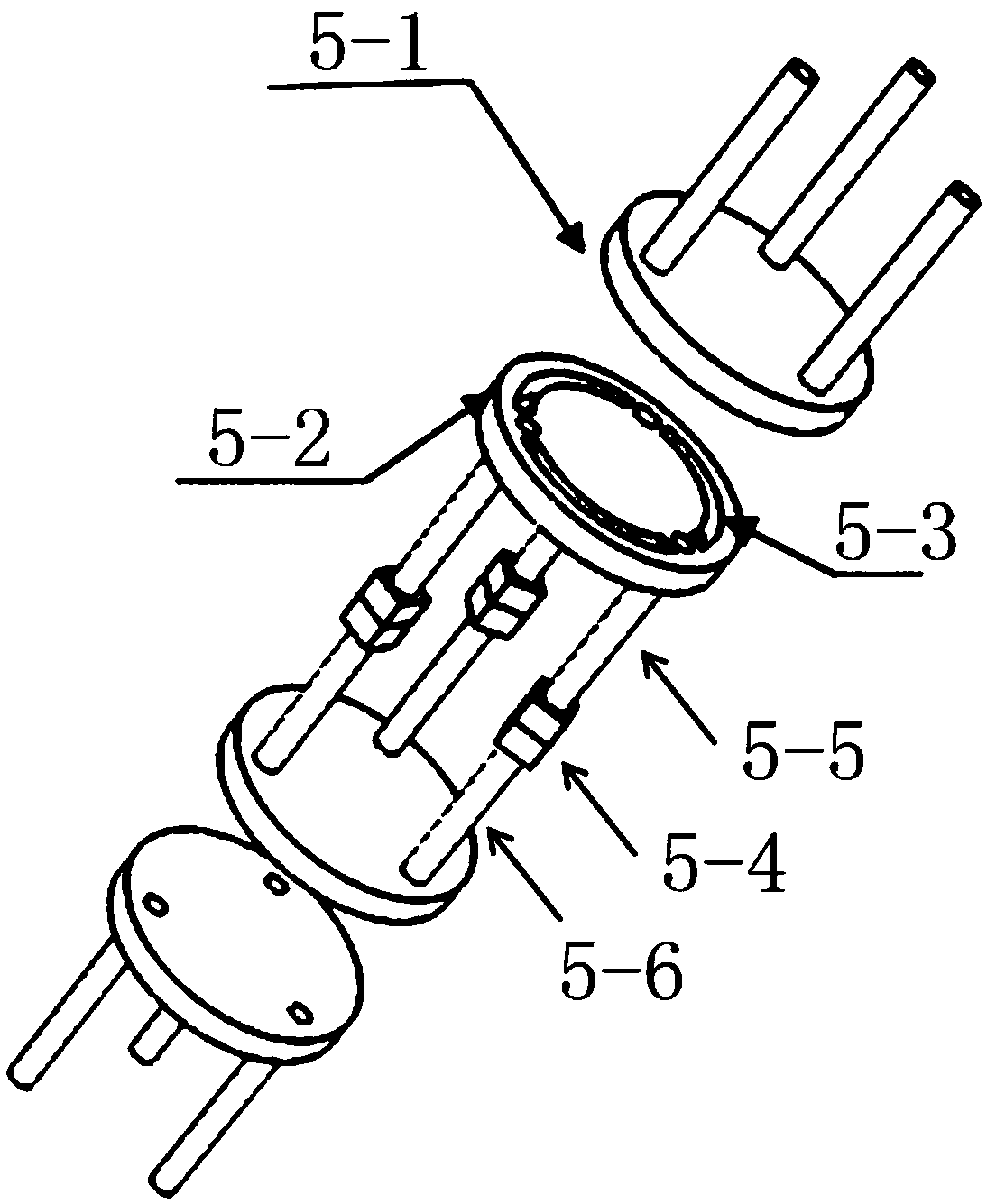

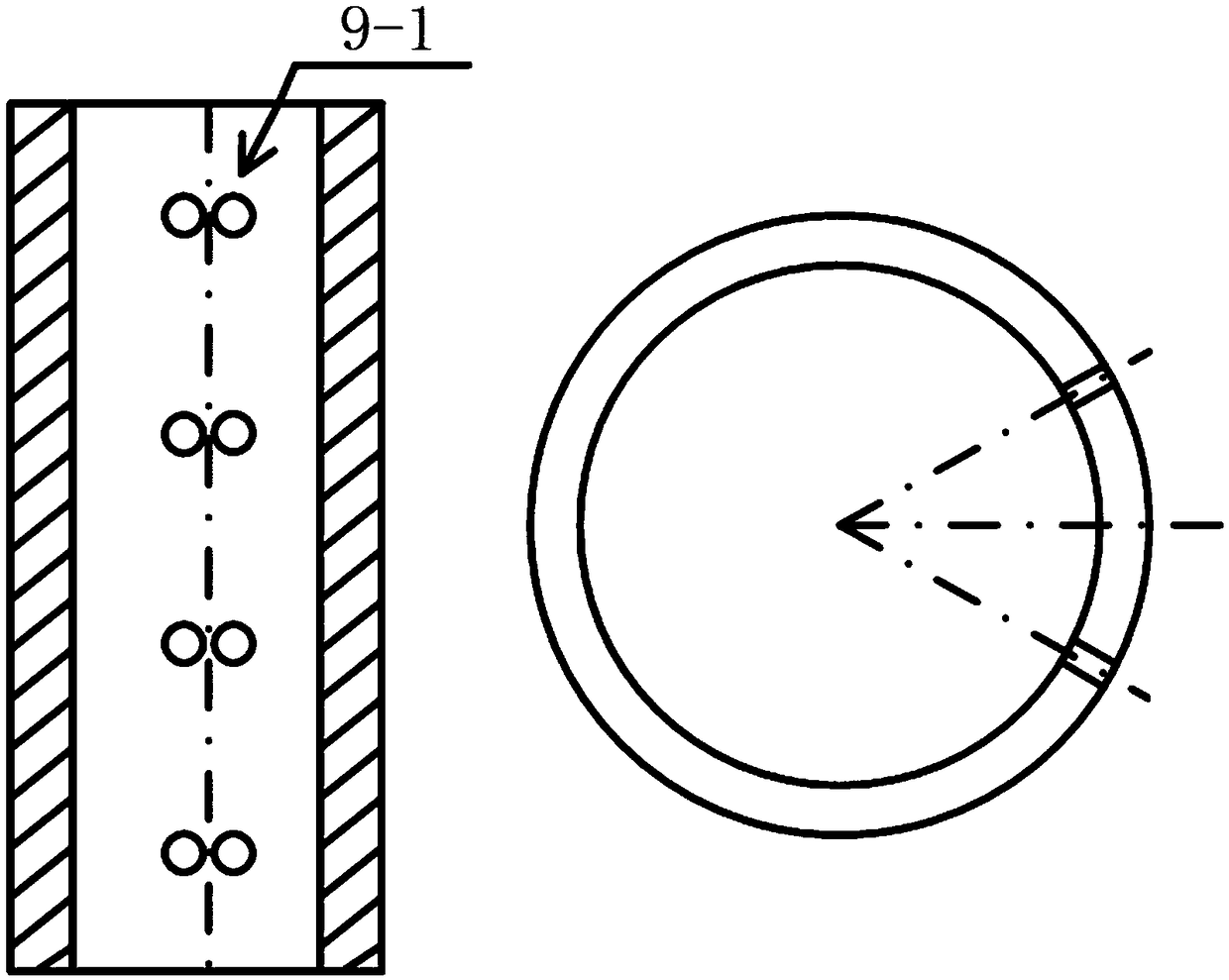

[0032] combine Figure 1 to Figure 3 , the present invention proposes a SCR reactor soot blowing system, which is mainly composed of an air bottle, a decompression system, a control system, a rotary pressure pulse converter, and a power unit. The soot blowing pipeline of the SCR reactor soot blowing system proposed by the present invention is a stainless steel pipeline with regularly arranged soot blowing holes, and the variable pressure compressed air generated by the rotary pressure pulse converter is used to control the SCR reactor. The dust accumulated on the surface of the catalyst is purged.

[0033] When the pressure difference between the inlet and outlet of the SCR reactor is large, the control system 4 of the soot blowing system will automatically turn on the dust purge mode. The compressed air solenoid valve 2 is opened, and the compressed air in the air b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com