Preparation method of aluminum-coated magnesium composite rod wire rod

A composite rod and aluminum-coated magnesium technology, which is applied in the field of composite metal processing, can solve the problems that aluminum-coated magnesium double-gold composite materials cannot be used, the product range is too narrow, and energy consumption is high, so as to eliminate adverse effects, avoid excessive fusion and Effect of diffusion reaction and process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

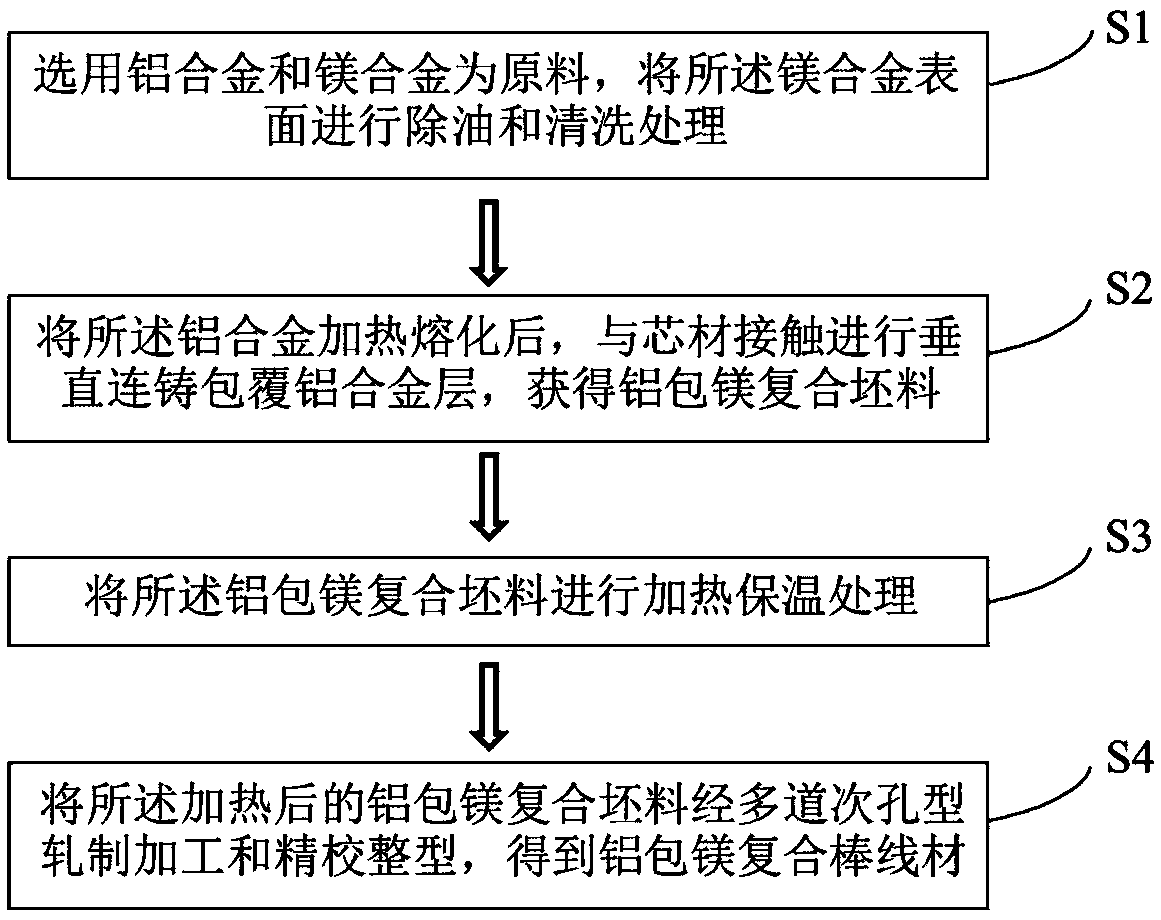

[0043] refer to figure 1 , figure 2 with image 3 , the embodiment of the present invention provides a method for preparing an aluminum-clad magnesium composite rod and wire, which specifically includes the following steps:

[0044] S1. Using magnesium alloy 1 and aluminum alloy 2 as raw materials, degreasing and cleaning the surface of the magnesium alloy 1;

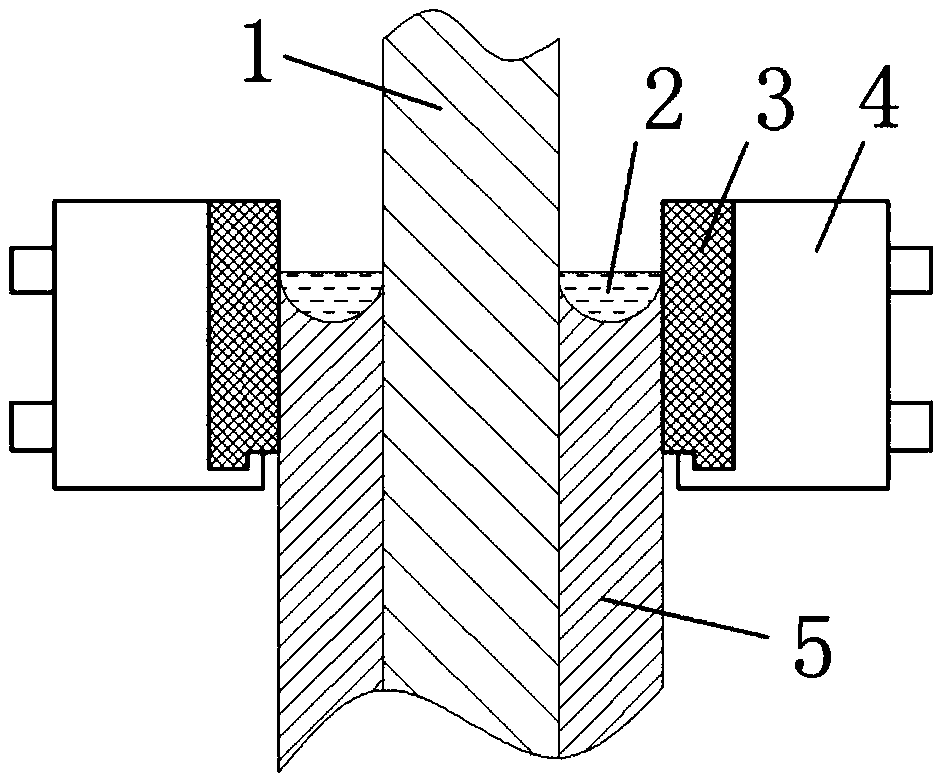

[0045] S2. Heat and melt the aluminum alloy 2 and pour it into the inner cavity of the annular split heat conduction module 3. The annular split heat conduction module 3 is assembled on the inner wall of the crystallizer 4. The liquid aluminum alloy 2 is in contact with the surface of the magnesium alloy 1 and is on the surface. solidification to form a coated aluminum alloy layer 5, and obtain an aluminum-clad magnesium composite billet;

[0046] S3, heating the aluminum-clad magnesium composite billet;

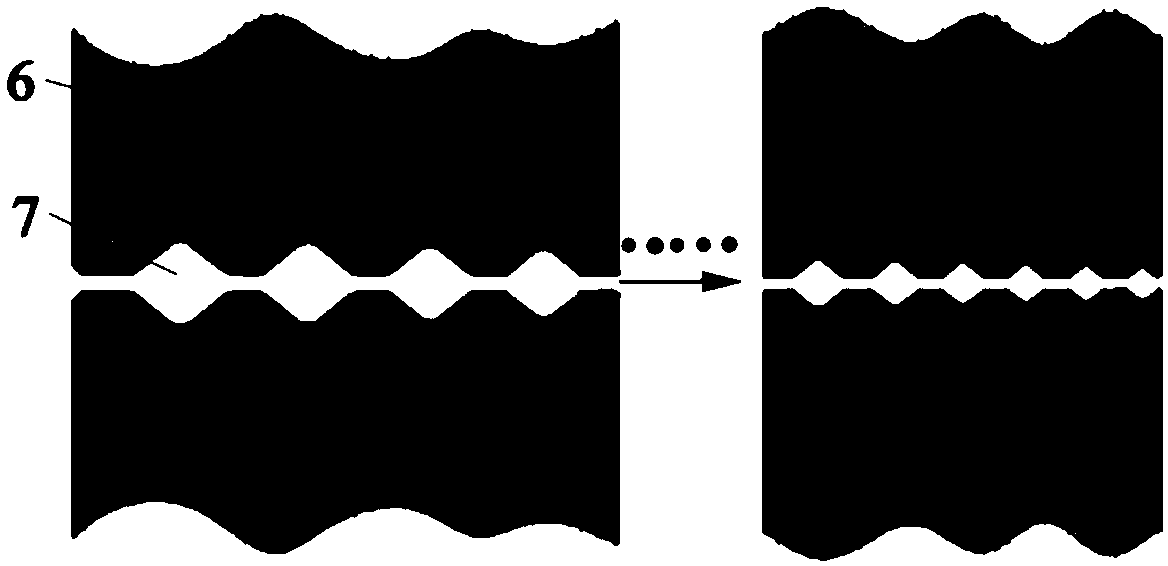

[0047] S4, subjecting the heated aluminum-clad magnesium composite billet to multi-pass pass rolling and fine-...

Embodiment 1

[0063] In this embodiment, industrial pure magnesium (≧99.94wt.%) with a diameter of 10mm is used as the core material, and industrial pure aluminum (≧99.79wt.%) is used as the cladding layer material. The outer surface of the pure magnesium rod is polished with a steel brush and cleaned by chemical methods to remove oil and oxide layers, and then it is placed in the center of the crystallizer and fixed with the traction device.

[0064] Install the annular split graphite module (made of high-purity graphite, with a carbon content of 99.96%) on the inner wall of the crystallizer, the outer wall of the module is in close contact with the inner wall of the crystallizer, the thickness is 11mm, the height of the inner wall is 23mm, and the inner cavity size is 20mm; The pure aluminum is heated and melted in the furnace, the heating temperature is 740°C, the temperature is lowered to 700°C for 5 minutes after refining and slag removal, and then the aluminum metal liquid is poured in...

Embodiment 2

[0068] In this embodiment, industrial pure magnesium (≧99.94wt.%) with a diameter of 16mm is used as the core material, and industrial pure aluminum (≧99.79wt.%) is used as the cladding layer material. The outer surface of the pure magnesium rod is polished with a steel brush and cleaned by chemical methods to remove oil and oxide layers, and then it is placed in the center of the crystallizer and fixed with the traction device.

[0069] The annular split graphite module is installed on the inner wall of the crystallizer, the outer wall of the module is in close contact with the inner wall of the crystallizer, the thickness is 6mm, the height of the inner wall is 42mm, and the inner cavity size is 30mm; the pure aluminum is heated and melted in a resistance heating furnace at a heating temperature of 740°C, After refining and slag removal, the temperature is lowered to 700°C, and then the aluminum metal liquid is poured into the inner cavity of the crystallizer to contact the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com