Culture method for high-performance synchronously denitrifying and desulphurizing anaerobic sludge

An anaerobic sludge and culture method technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as damage to the survival of aquatic plants and other organisms, acidification and eutrophication, etc. , to achieve the effect of enhancing operation stability, fast settling speed and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

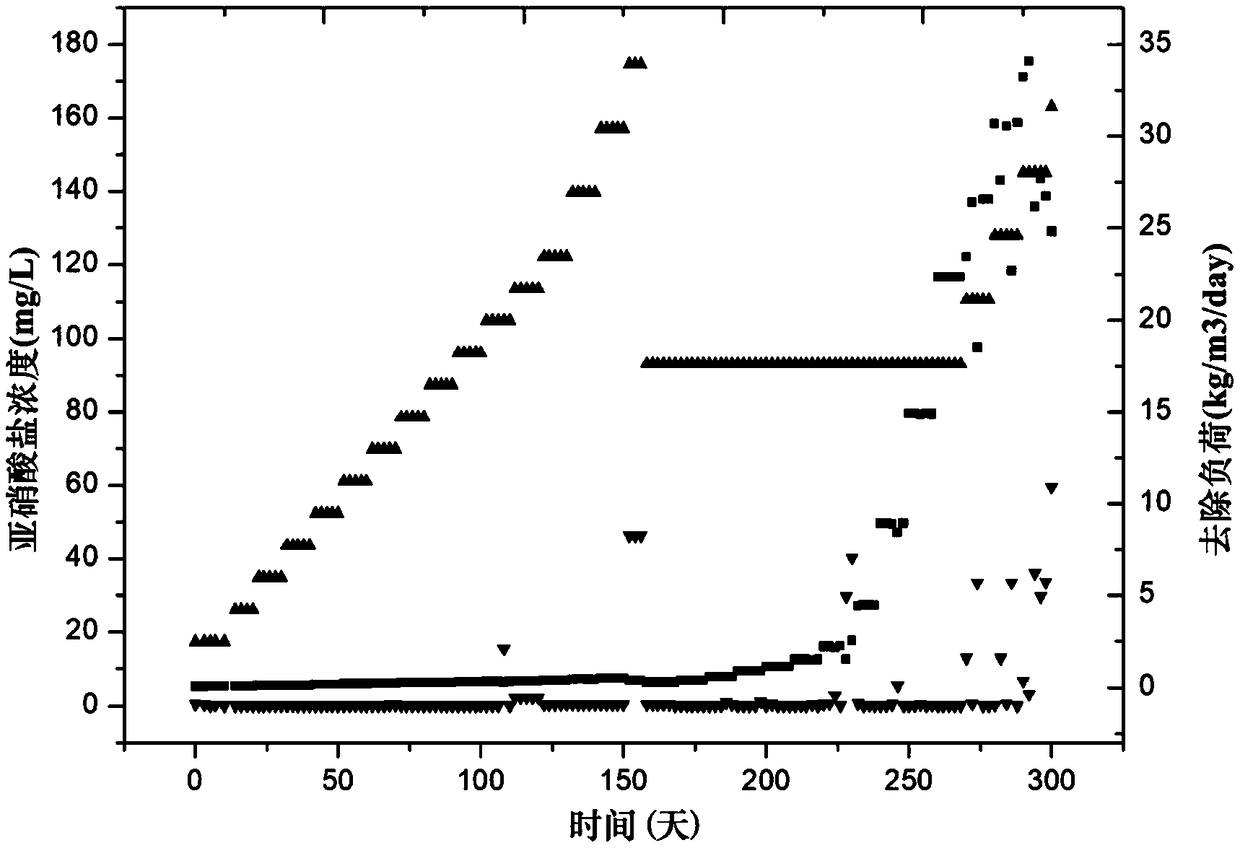

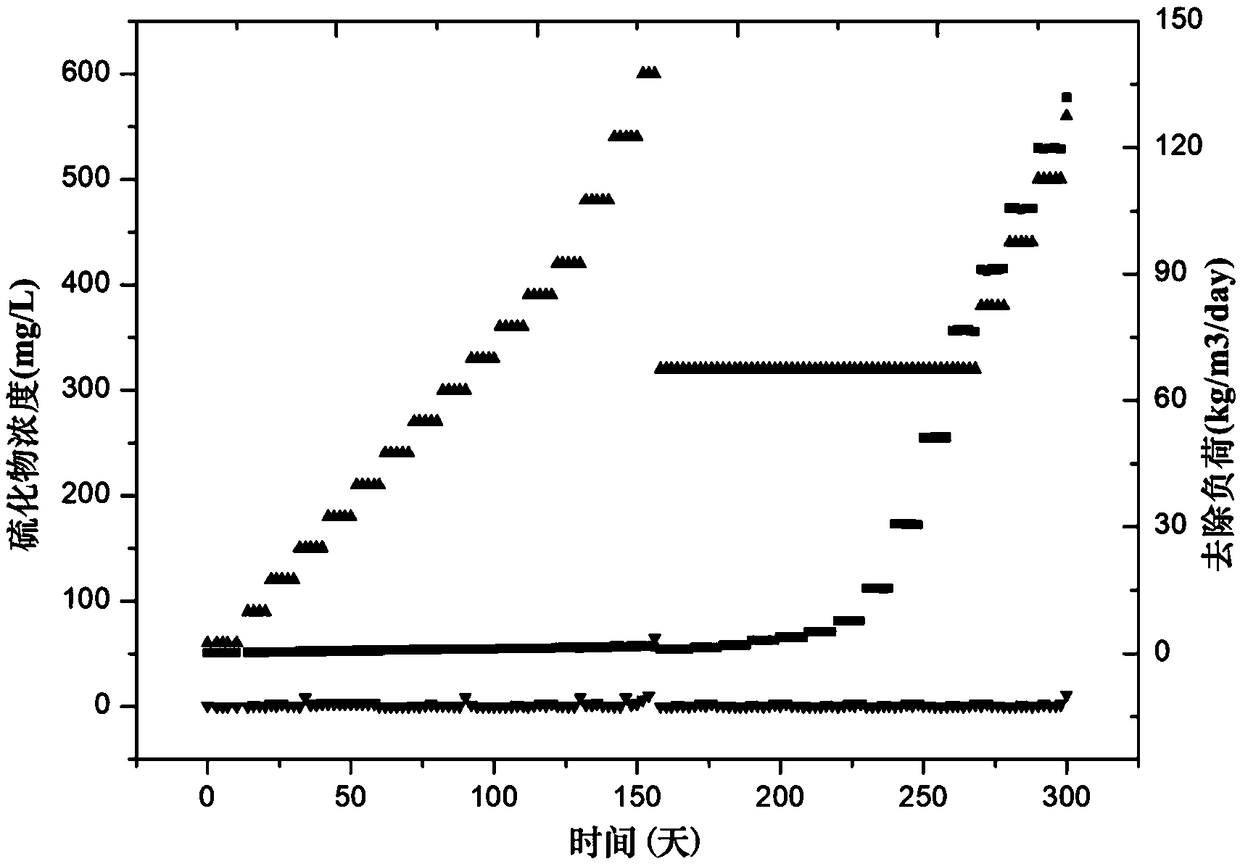

[0025] Under continuous flow conditions, an upflow anaerobic sludge bed reactor with an effective volume of 0.8L is used, and the anaerobic ammonium oxidation granular sludge cultivated at a constant temperature of 35°C is used as the inoculation sludge. The denitrification performance of the inoculation sludge is as high as 18.6kg·m -3 d -1 , the amount of inoculated sludge is 80% of the effective volume of the reactor. At the same time, with 60mg·L -1 Na 2 S·9H 2 O's culture medium A and containing 18mg·L -1 NaNO 2 The culture medium B of each medium was fed independently (in order to avoid substrate reaction and sulfide precipitation, the strategy of separating different culture liquids was adopted for the reactor water intake, and the pH of the water intake was not adjusted), and the hydraulic retention time of the reactor was controlled to 8h. The molar ratio of nitrite to sulfide is 2:3, and the operation is stable for 10 days.

[0026] The composition of culture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com