Grease epoxidation continuous production method

A production method and epoxidation technology, applied in organic chemistry and other directions, can solve the problems of high heat release, complex equipment volume, large stirring power, etc., and achieve the effects of high product selectivity, simple engineering scale-up, and simple equipment structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

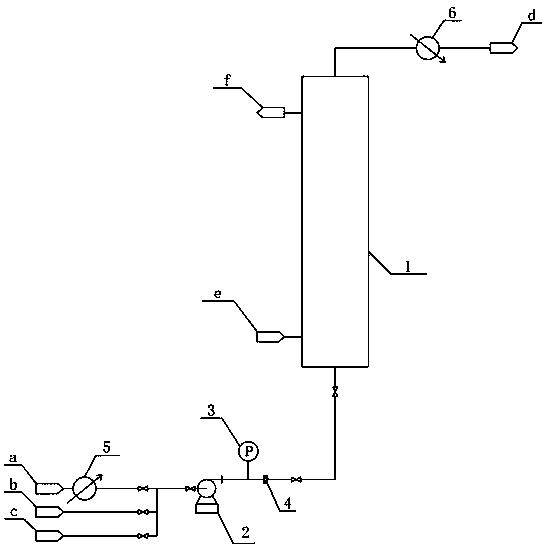

[0026] refer to figure 1 , add PEG-30 with a mass fraction of 0.03% to raw oil (soybean oil) with an iodine value of 125, and formic acid with a mass fraction of 95% and hydrogen peroxide with a mass fraction of 50%, in a molar ratio of 1:1.5 : 0.3 (carbon-carbon double bond in the raw material oil: hydrogen peroxide: formic acid), through the grease inlet a, the formic acid inlet b and the hydrogen peroxide inlet c respectively by the pump 2 continuous suction (wherein the oil inlet a and the pump A preheater 5 is installed on the pipeline between 2 to preheat the mixture of raw oil and PEG-30 to 60°C), and then transported to the hydraulic cavitation element 4 to realize the two-phase mixing of oil and water (in pump 2 and hydraulic cavitation A pressure gauge 3 is set on the pipeline between the elements 4 to control the pressure of the reaction liquid entering the hydraulic cavitation element 4 to be 2 bar, where the hydraulic cavitation element 4 is a Venturi tube);

[0...

Embodiment 2

[0030] refer to figure 1 , adding PEG-30 with a mass fraction of 0.05% in the raw oil (fatty acid methyl ester) with an iodine value of 120, with formic acid with a mass fraction of 95% and hydrogen peroxide with a mass fraction of 50%, the molar ratio is 1: 1.5:0.3 (carbon-carbon double bond in raw oil: hydrogen peroxide: formic acid), respectively through the grease inlet a, the formic acid inlet b and the hydrogen peroxide inlet c, are continuously inhaled by the pump 2 (wherein the oil inlet a and A preheater 5 is installed on the pipeline between the pumps 2 to preheat the mixture of raw oil and PEG-30 to 60°C), and then transported to the hydraulic cavitation element 4 to realize the two-phase mixing of oil and water (in the pump 2 and the hydraulic air A pressure gauge 3 is set on the pipeline between the chemical elements 4 to control the pressure of the reaction liquid entering the hydraulic cavitation element 4 to be 3 bar, where the hydraulic cavitation element 4 is...

Embodiment 3

[0034] refer tofigure 1 , adding PEG-30 with a mass fraction of 0.1% in the raw oil (octyl fatty acid ester) with an iodine value of 90, with formic acid with a mass fraction of 95% and hydrogen peroxide with a mass fraction of 50%, the molar ratio is 1: 1.5:0.3 (carbon-carbon double bond in raw oil: hydrogen peroxide: formic acid), respectively through the grease inlet a, the formic acid inlet b and the hydrogen peroxide inlet c, are continuously inhaled by the pump 2 (wherein the oil inlet a and A preheater 5 is installed on the pipeline between the pumps 2 to preheat the mixture of raw oil and PEG-30 to 60°C), and then transported to the hydraulic cavitation element 4 to realize the two-phase mixing of oil and water (in the pump 2 and the hydraulic air A pressure gauge 3 is set on the pipeline between the chemical elements 4 to control the pressure of the reaction liquid entering the hydraulic cavitation element 4 to be 4 bar, where the hydraulic cavitation element 4 is a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com