Molten nitrate salt heat transfer and heat accumulation medium and preparation method thereof

A heat storage medium and nitrate technology, applied in lighting and heating equipment, chemical instruments and methods, solar heat storage, etc., can solve the problems of high melting point, easy solidification, and blocked pipes, and achieve low melting point, low cost, and improved The effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A kind of preparation of nitrate heat transfer heat storage medium:

[0060] (1) Take by weighing 42.7g calcium nitrate, 48.2g sodium nitrate, 9.1g lithium nitrate mixed grinding;

[0061] (2) Dry the uniformly mixed powder above in a drying oven at 80°C for 48 hours, then raise the temperature to 150°C and heat for 48 hours, so that the water in the mixture overflows;

[0062] (3) Heating in a muffle furnace at 300° C. for 12 hours, and cooling to obtain the nitrate heat transfer and heat storage medium.

Embodiment 2

[0064] A kind of preparation of nitrate heat transfer heat storage medium:

[0065] (1) Take by weighing 44.8g calcium nitrate, 50.5g sodium nitrate, 4.7g lithium nitrate mixed grinding;

[0066] (2) Dry the uniformly mixed powder above in a drying oven at 60°C for 36 hours, then heat up to 120°C for 36 hours, so that the water in the mixture overflows;

[0067] (3) Heating in a muffle furnace at 300° C. for 12 hours, and cooling to obtain the nitrate heat transfer and heat storage medium.

Embodiment 3

[0069] A kind of preparation of nitrate heat transfer heat storage medium:

[0070] (1) Take by weighing 20g calcium nitrate, 70g sodium nitrate, 10g lithium nitrate mixed grinding;

[0071] (2) Dry the uniformly mixed powder above in a drying oven at 100°C for 60 hours, then heat up to 180°C for 60 hours, so that the water in the mixture overflows;

[0072] (3) Heating in a muffle furnace at 300° C. for 12 hours, and cooling to obtain the nitrate heat transfer and heat storage medium.

PUM

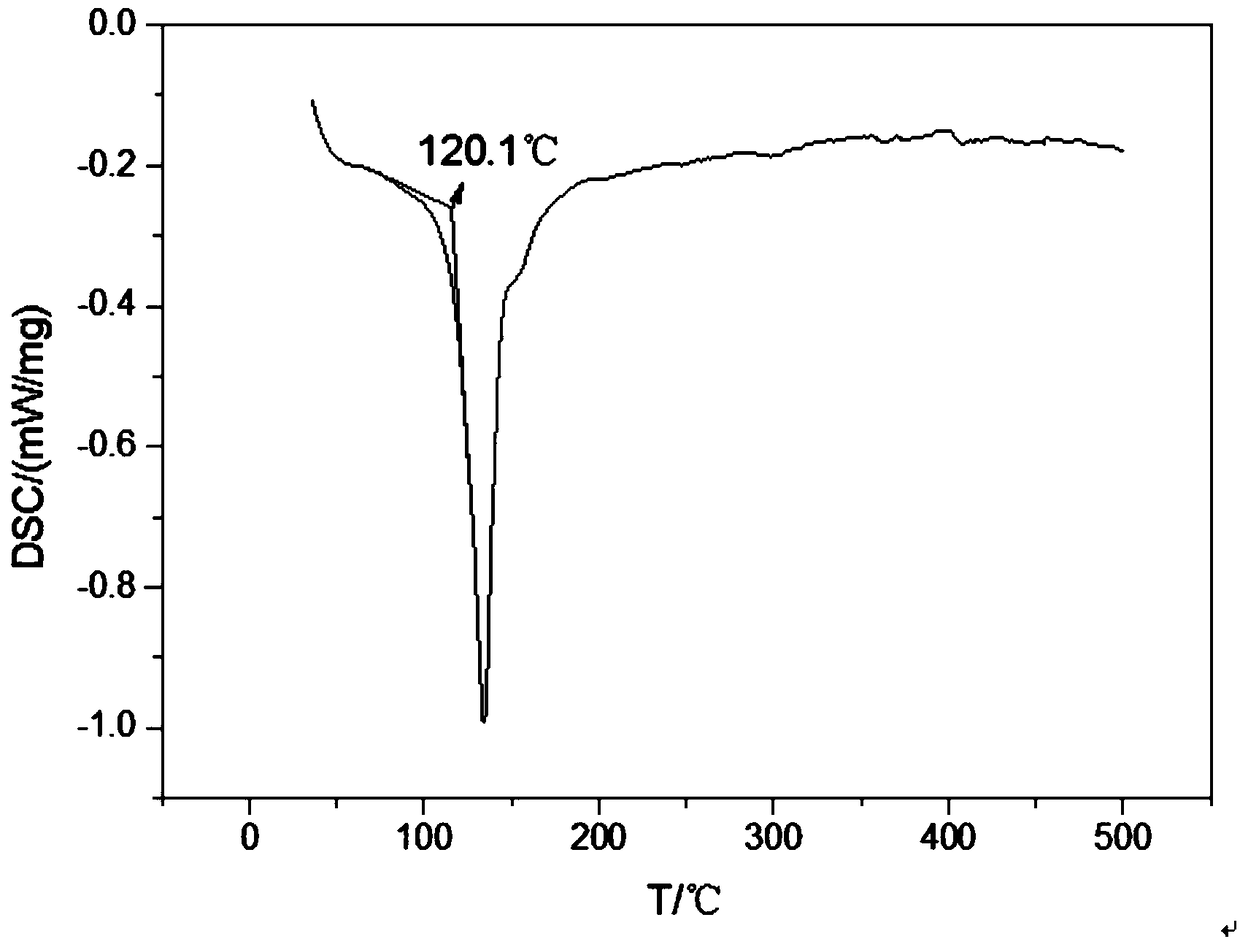

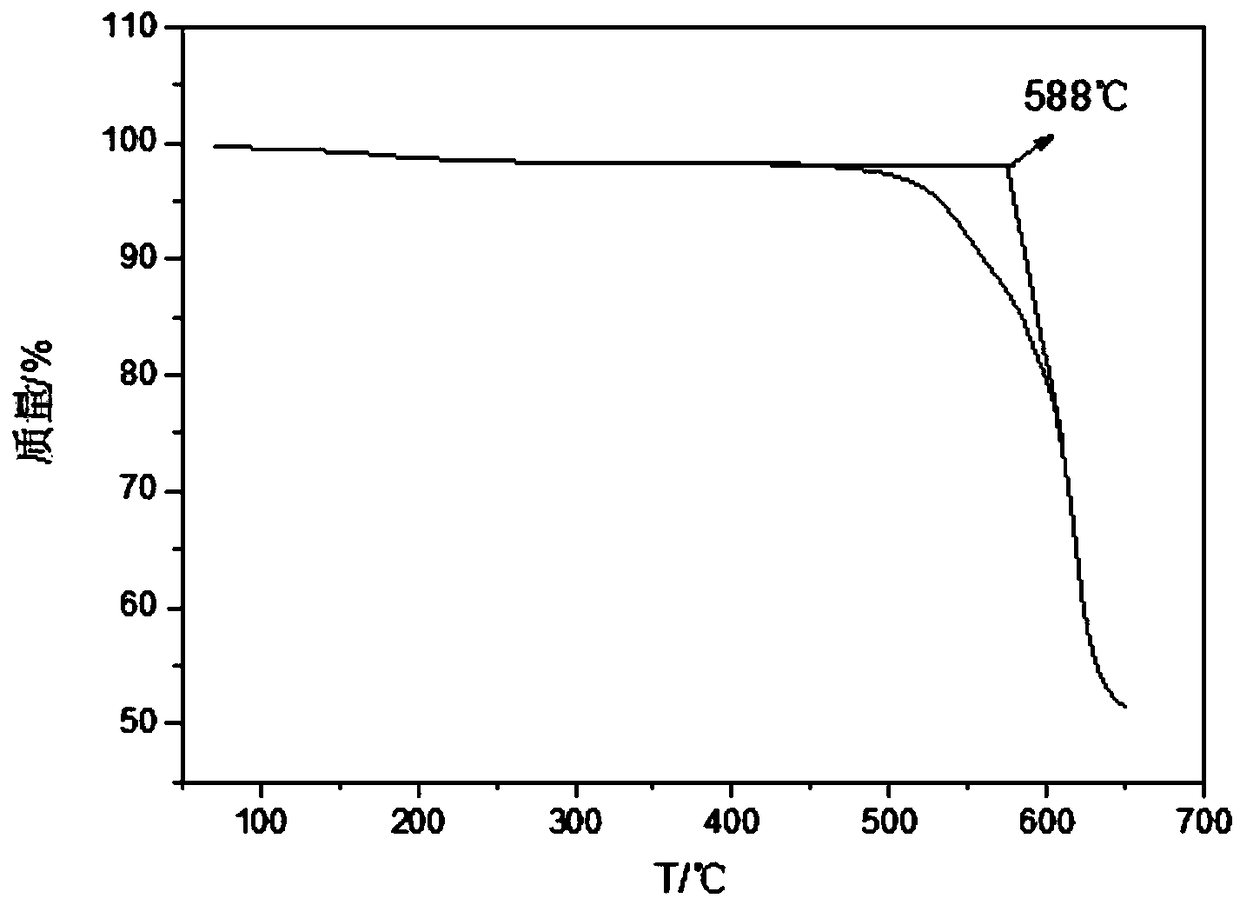

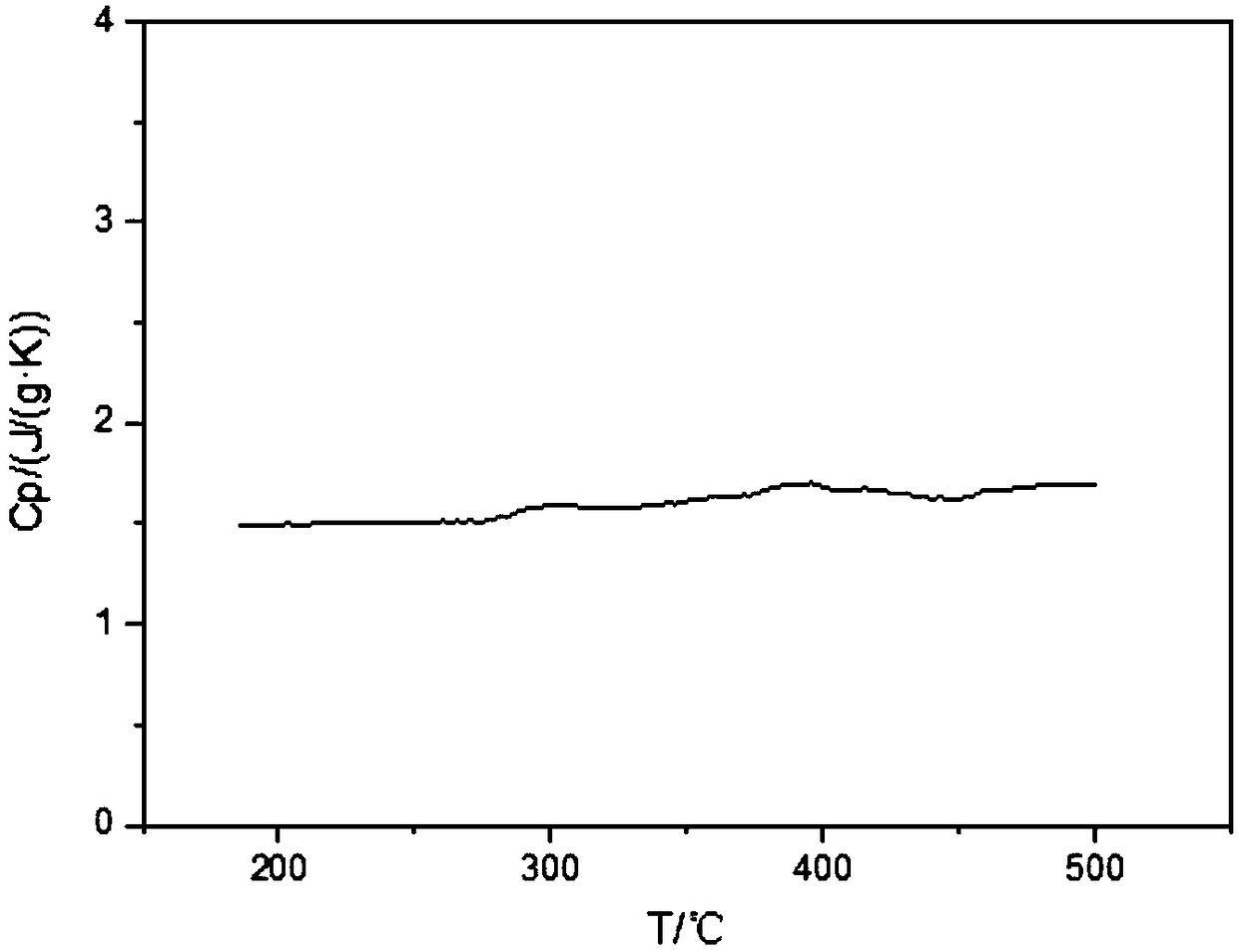

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com