Energy-saving and efficient annealing furnace

An annealing furnace, high-efficiency technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of high energy consumption, affecting the service life of the heating furnace, increasing the heat loss of the furnace body, and reducing dust and flue gas emissions. , the effect of optimizing energy consumption structure and reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

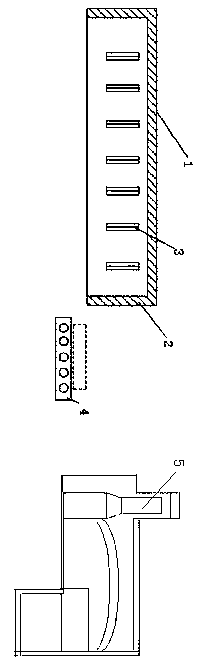

[0014] Embodiment: An energy-saving and high-efficiency annealing furnace mainly includes a furnace body 1. The furnace body 1 includes a furnace body shell 2, a furnace temperature system 3, a track 4, and a furnace top exhaust device 5. The furnace body shell 2 is welded by shaped steel and steel plates , The temperature control of the furnace temperature system 3 is divided into three areas, in which the heating area has the upper part of the wall and the off-duty staggered layout, the furnace temperature system 3 is equipped with four burners, and the furnace lining inside the furnace body 1 is a refractory fiber structure.

[0015] In this embodiment, the top exhaust device 5 is made of all-fiber structure. The cooling speed in the furnace is slow after the power is cut off. In order to meet the cooling process requirements, two sets of cooling exhaust devices are installed on the top of the furnace, which are controlled by the manual mechanism on the side of the furnace. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com