Method for preheating sintering mixture in steel works

A technology for sintering mixtures and mixtures, applied in the field of comprehensive utilization of resources, can solve the problems of insufficient steam pressure, clogging of steam nozzles, unsatisfactory preheating effect, etc., and achieve the effects of saving fuel consumption, increasing temperature, and improving the quality of sintered minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

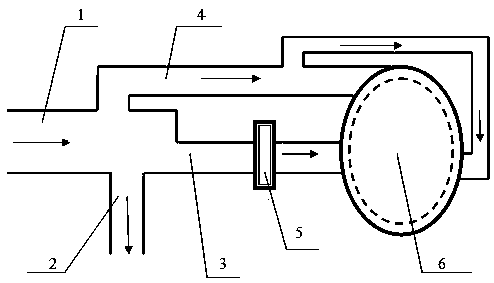

[0019] The method for preheating the mixture of Xiangtan Iron and Steel's new second sinter mixture, including:

[0020] (1) The waste heat of the new 2nd sintering ring cooler of Hunan Iron and Steel Co., Ltd. is collected to generate medium-pressure steam with a pressure of 1.5Mpa for power generation. A small part of the low-pressure steam with a pressure of 0.3Mpa is kept in the sintering head electric dust collector, and most of it is passed into the sintering machine. The mixing silo preheats the mixture.

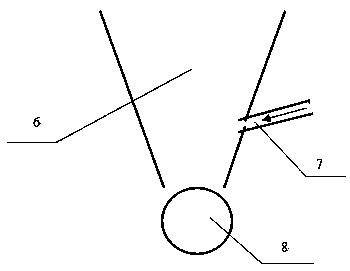

[0021] (2) A total of 42 steam nozzles 7 are installed in the mixing silo of the new No. 2 sintering plant of Xiangshan Iron and Steel Co., Ltd. The total cross-sectional area of the 42 steam nozzles 7 is 0.013188㎡, while the original design of the steam supply pipeline is DN80, and its cross-sectional area is 0.005024㎡. The difference between the two is 0.008164㎡. That is to say, the gas supply is seriously insufficient, and the total amount of gas supply must be ...

Embodiment 2

[0026] The method for preheating the sintering mixture of Xiangtan Iron and Steel Co., Ltd. includes:

[0027] (1) The waste heat of the sintering ring cooler of Hunan Iron and Steel Co., Ltd. is collected to generate medium-pressure steam with a pressure of 1.4Mpa for power generation. A small part of the low-pressure steam with a pressure of 0.28Mpa is kept in the sintering head electric dust collector, and most of it is passed into the sintering mixture The silo preheats the mixture.

[0028] (2) A total of 38 steam nozzles 7 are installed in the mixing silo of Hunan Iron and Steel No. 1. The total cross-sectional area of the 38 steam nozzles 7 is 0.011932㎡, while the original design of the steam supply pipeline is DN80, and its cross-sectional area is 0.005024㎡. The difference between them is 0.006908㎡. That is to say, the gas supply is seriously insufficient, and the total amount of gas supply must be increased. The DN200 steam main pipe at the head of the sintering m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com