Novel high-resistance electrothermal alloy Cr20Ni80Al and preparation method thereof

A cr20ni80al, electrothermal alloy technology, applied in the field of electrothermal alloys, can solve the problems of insufficient durable strength and service life, insufficient resistivity, unweldability, etc., achieve excellent electrical characteristics, increase resistivity, and reduce brittle phase effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

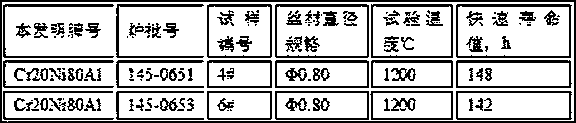

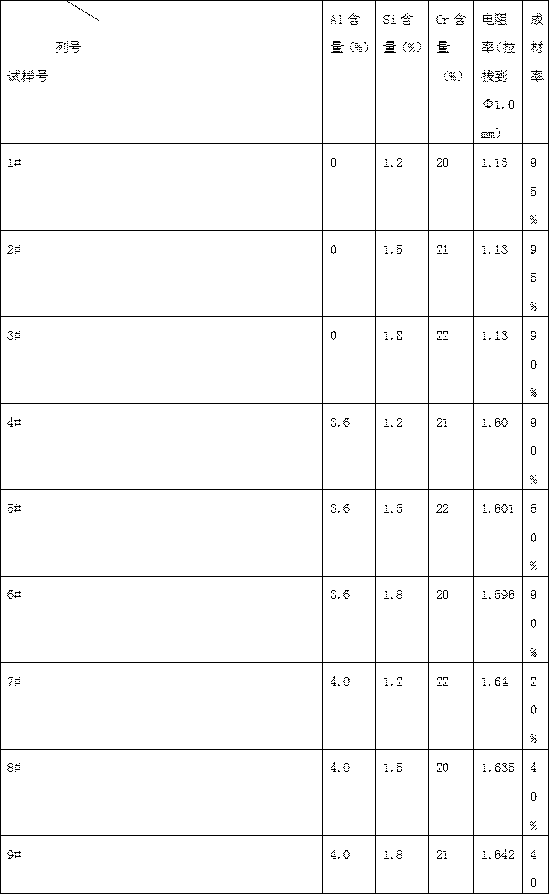

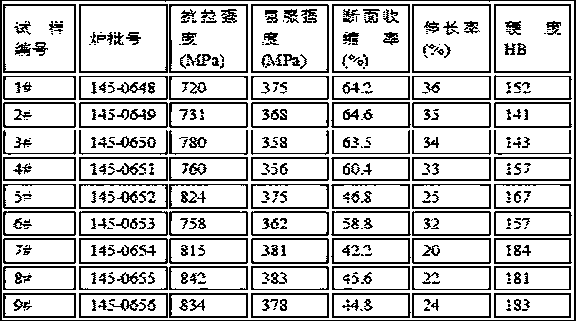

[0028] The features and advantages of the present invention will be described in detail below with reference to specific examples and comparative experiments.

[0029] Below by using a three-level orthogonal table L 9 (3 4 ) design experiments, according to the existing experience and description in the Electrothermal Alloy Handbook that the content of Al, Si, Cr can directly affect the resistivity of the material, and according to the upper and lower line principle of element design, three groups of variables of these three factors are used to carry out the research. The process is described in Table 1:

[0030] Table 1

[0031]

[0032] The preparation process of the above nine groups of embodiments is as follows: select pure metal materials with a content of Ni, Cr, Mn, Fe, Si, AL, Ti, and Zr greater than 99% as raw materials for production and manufacture, and the remaining elements are controlled proportionally.

[0033]According to the above-mentioned nine groups o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com