FRP pipe-PHC pipe pile interlayer in-fill concrete combined structure

A technology of PHC pipe piles and composite structures, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems affecting structural safety, insufficient durability and corrosion resistance, and low design life of pipe piles, so as to improve the bearing capacity ability and bending stiffness, improving durability and seismic performance, and delaying the development of longitudinal micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

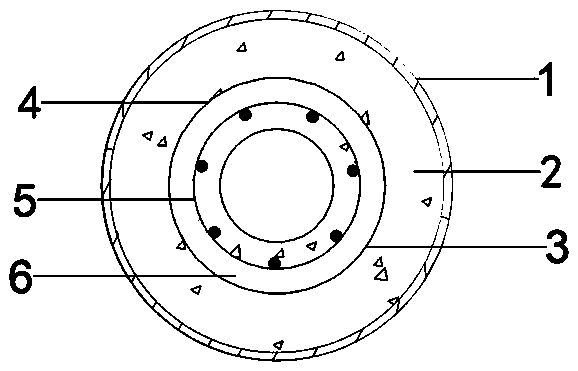

[0024] Such as figure 1 As shown, the composite structure of FRP pipe-PHC pipe pile interlayer filled with concrete in this embodiment includes the FRP pipe 1 as the outer wall, the PHC pipe pile core pipe 3 as the inner wall, and the PHC pipe pile core pipe 3 poured on the FRP pipe and the PHC pipe pile. The concrete layer 2 between the core pipes, the FRP pipe 1, the PHC pipe pile core pipe 3 and the concrete layer 2 form a hollow pipe pile, and the geometric centers of the FRP pipe and the PHC pipe pile core pipe coincide.

[0025] The cross section of the FRP pipe 1 is circular, and the cross section of the PHC pipe pile core pipe 3 is circular.

[0026] In addition to the carbon fiber CFRP pipe itself, the outer wall FRP pipe can also be made of glass fiber GFRP pipe or aramid fiber AFRP pipe according to local conditions.

[0027] The concrete layer can be poured with ordinary concrete and self-compacting concrete, and can also be filled with sea sand and gravel from of...

Embodiment 2

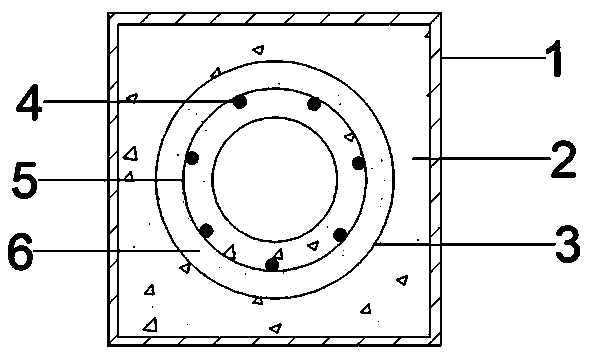

[0032] The cross-section of the FRP pipe 1 in this embodiment is square, and the rest are the same as in Embodiment 1.

Embodiment 3

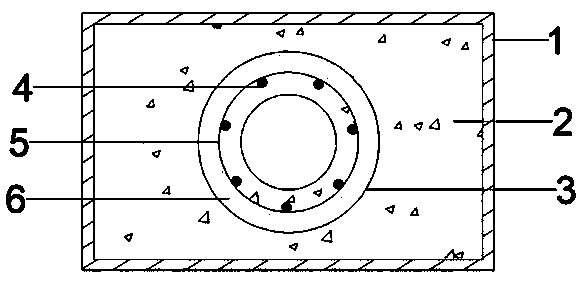

[0034] The cross-section of the FRP pipe 1 in this embodiment is rectangular, and the rest are the same as in Embodiment 1.

[0035] The invention can be specifically applied to the field of pile foundations in civil engineering, and is especially suitable for supporting piles under long-term harsh geological environments and marine engineering with high requirements on corrosion resistance and durability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com