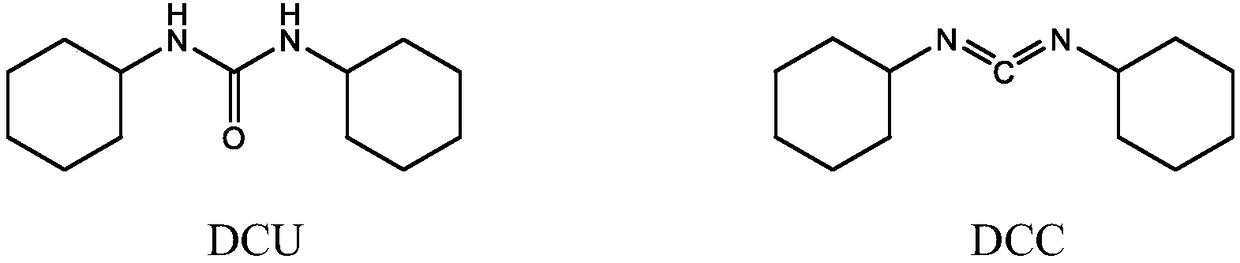

Preparation method to recycle pyribenzoxim byproduct dicyclohexylurea

A technology of dicyclohexylurea and saflufenacil, which is applied in the field of agrochemicals, can solve problems affecting the continuous production of saflufenacil, inconsistencies in green manufacturing, and potential safety hazards, and achieve safe and green industrial production and waste utilization , the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

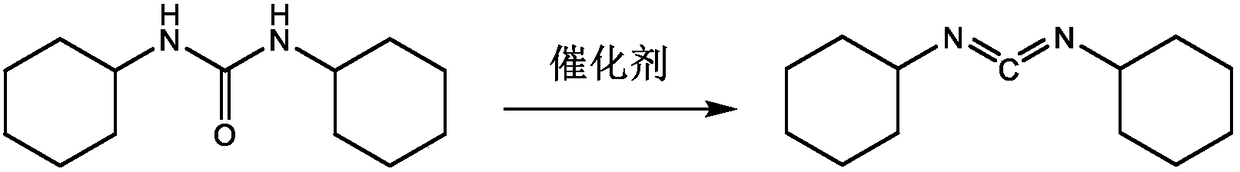

Method used

Image

Examples

Embodiment 1

[0025] Put the by-product DCU (170g) and the catalyst 1-phenyl-3-methyl-phosphole-1-oxide (3.4g) into a 1000mL reactor, heat to 150°C for reaction, and react at 150°C After 12 hours, cool to 80°C to react, filter to recover the catalyst, distill the filtrate under reduced pressure, collect fractions at 125-130°C (6mmHg), and cool to obtain white solid DCC with a yield of 84.4% and a purity of 98.3%.

Embodiment 2

[0027] Put the by-product DCU (170g) and the catalyst 1-phenyl-3-methyl-phosphole-1-oxide (1.7g) into a 1000mL reactor, heat to 160°C for reaction, and react at 160°C 8h, cooled to 70°C for reaction, recovered the catalyst by filtration, distilled the filtrate under reduced pressure, collected fractions at 125-130°C (6mmHg), and cooled to obtain white solid DCC with a yield of 88.2% and a purity of 98.1%.

Embodiment 3

[0029] Put the by-product DCU (170g) into a 1000mL reactor, recover the catalyst 1-phenyl-3-ethyl-phosphole-1-oxide (2.1g), heat to 140°C for reaction, and react at about 140°C React for 18 hours, cool to 60°C to react, filter to recover the catalyst, distill the filtrate under reduced pressure, collect fractions at 135-140°C (8mmHg), and cool to obtain white solid DCC with a yield of 85.1% and a purity of 98.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com