Variable component multi-pressure evaporation non-azeotropic refrigerant Rankine cycle system with ejector

A circulation system and injector technology, applied in the direction of machines/engines, steam applications, steam engine installations, etc., can solve problems such as limited heat exchange equipment design parameters, thermal performance limitations, system performance deterioration, etc., to achieve improved matching and enhanced adaptation performance, and the effect of improving power generation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

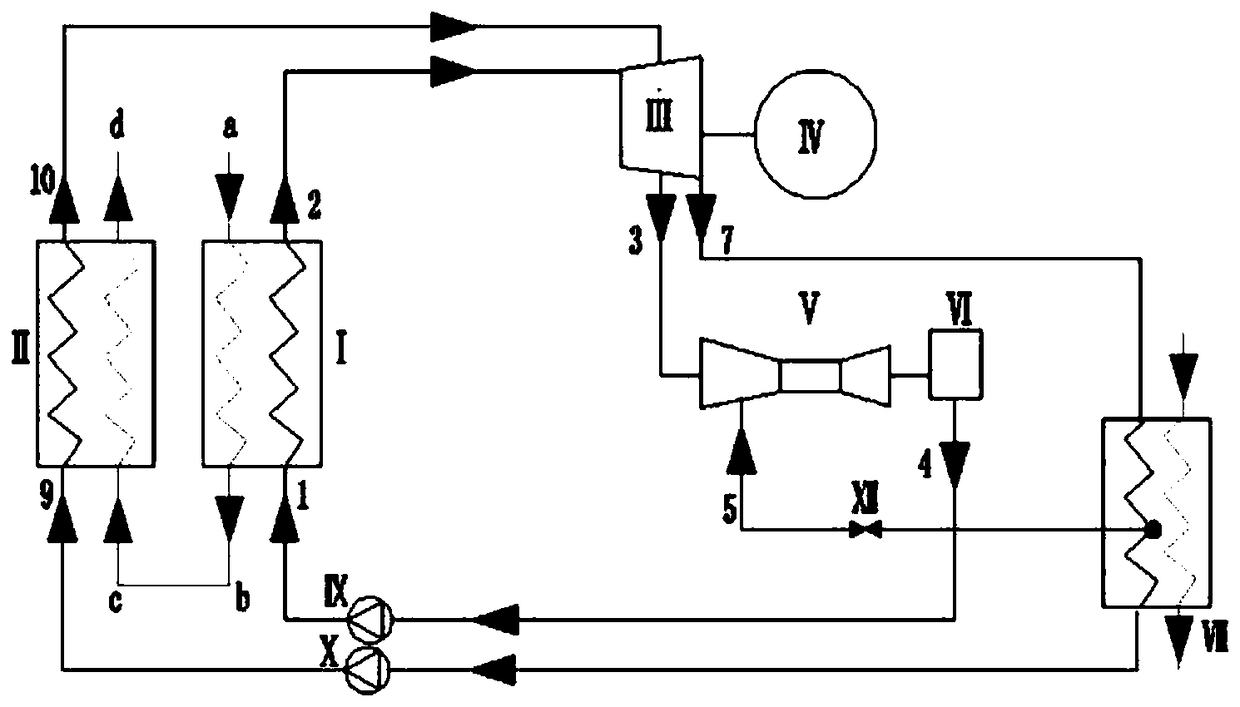

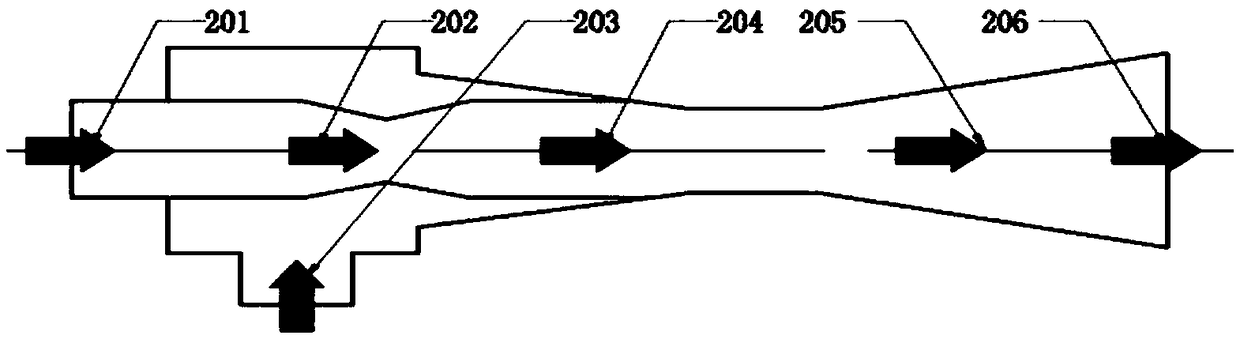

[0016] The present invention will be further described below in conjunction with the accompanying drawings. Among them, the direction marked by the arrow in the figure is the flow direction of the medium, and the description of the gas-liquid injector in this article takes Figure 2 as a reference standard.

[0017] Such as figure 1 As shown, a variable component multi-pressure evaporation zeotrope boiling organic Rankine cycle system with an ejector, such as figure 1 As shown, it includes an expander III, a circulation pump, an evaporator, a condenser VII and a gas-liquid ejector V, the working fluid outlet 3 of the expander III is connected to the working fluid inlet of the gas-liquid ejector V, and the expander The exhaust steam outlet 7 of the machine III is connected to the condenser VII, and the middle part of the condenser VII is provided with a pipeline connected to the low-pressure injection fluid inlet 5 of the gas-liquid ejector V, and the condenser VII is circulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com