Metal pipe and corrosion protection method thereof

A technology for metal pipes and outer pipes, applied in anti-corrosion coatings, alkali metal silicate coatings, pipes, etc., can solve the problems of needing improvement, inseparability, high cost, etc., to improve cathodic protection efficiency, facilitate spraying construction, and prevent corrosion The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

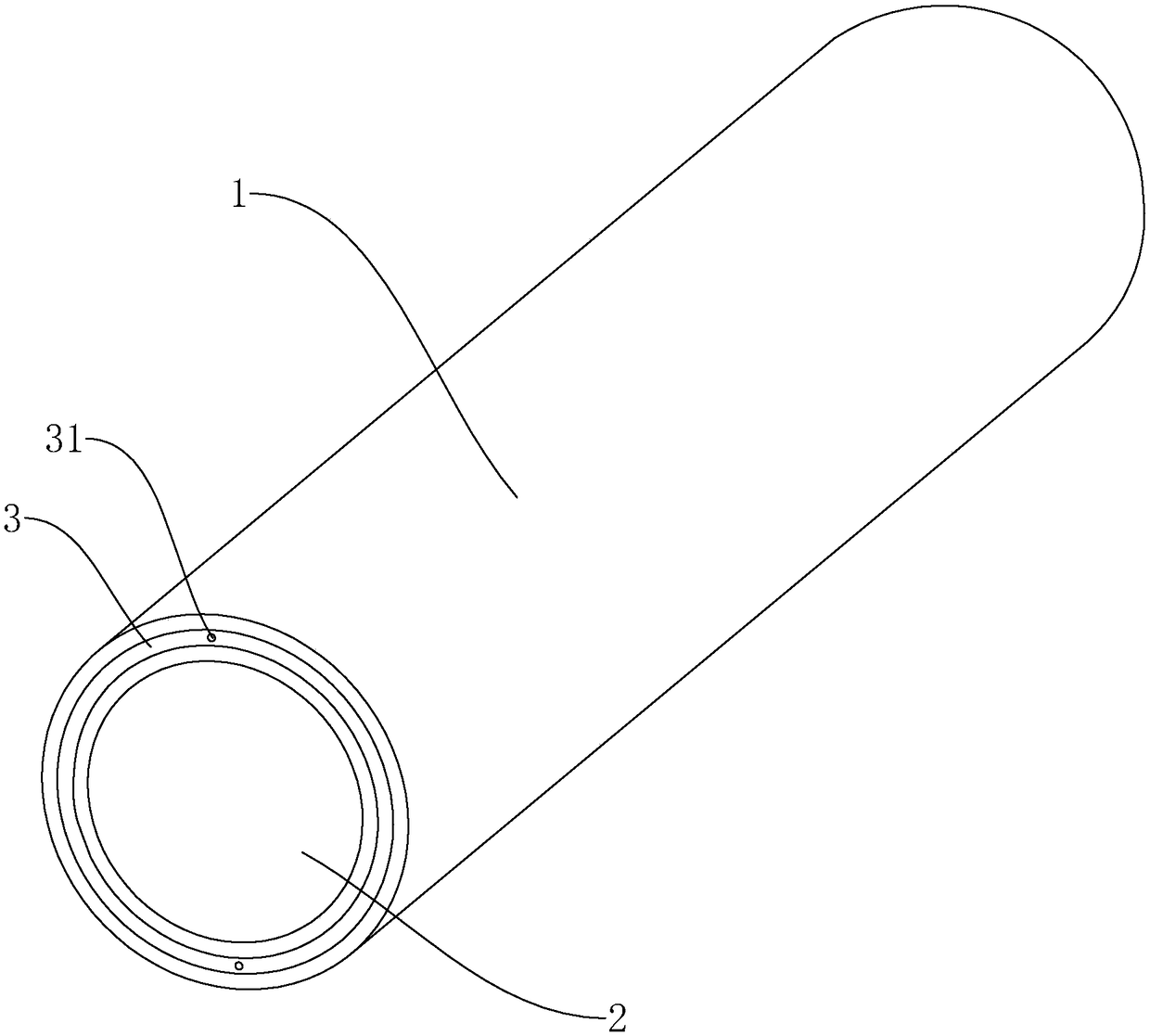

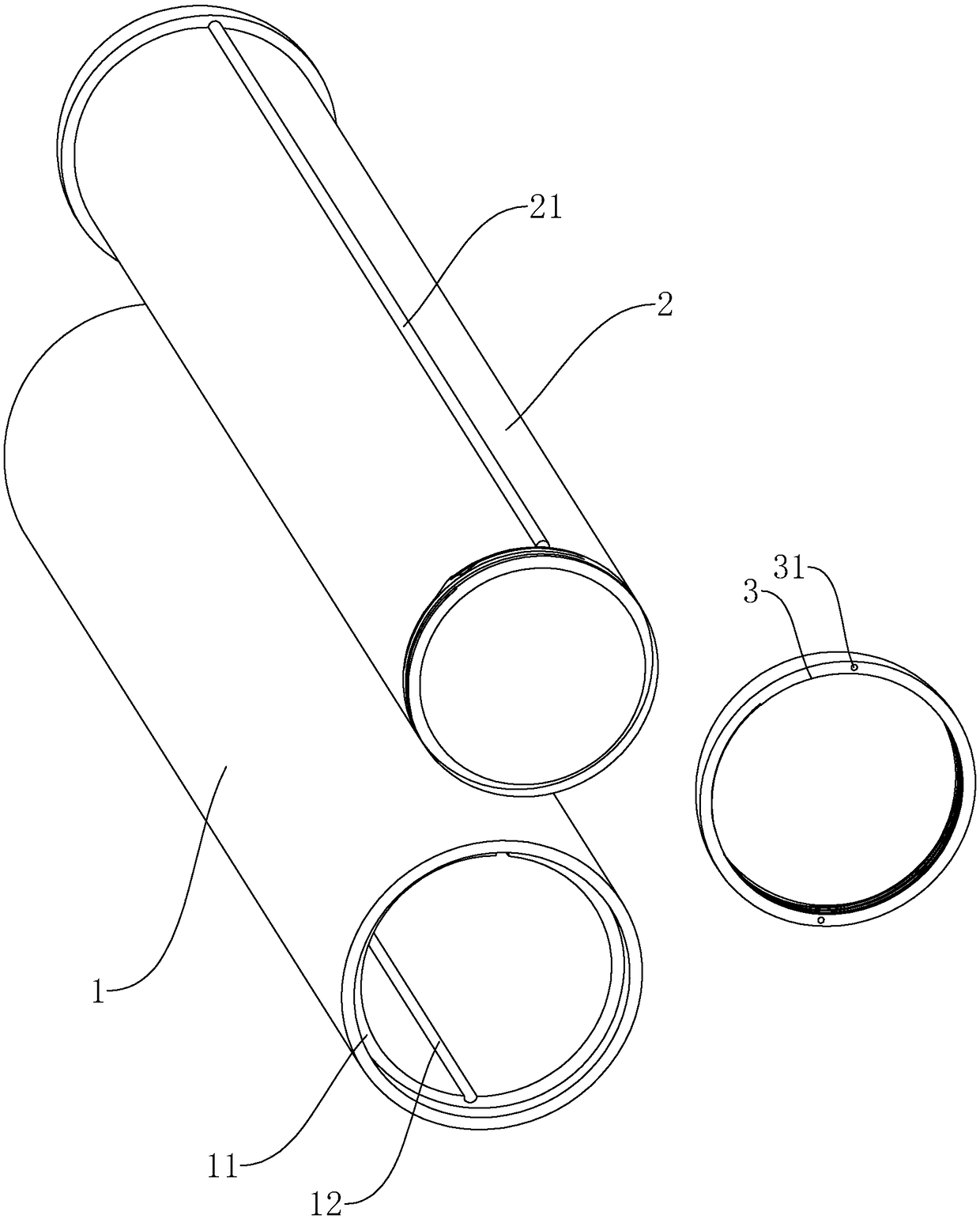

[0053] a metal tube such as figure 1 As shown, it includes the outer pipe 1 and the inner pipe 2. The inner pipe 2 is close to the inner wall of the outer pipe 1 and has the same length. Therefore, when the metal pipe is used to transport corrosive media such as brine and sulfuric acid, the inner wall of the inner pipe 2 contacts with it to resist corrosion. And the outer tube 1 is not prone to corrosion. The outer tube 1 can be made of high-strength metal material or alloy to provide high compressive strength, such as: iron, steel, etc.; the inner tube 2 can be made of corrosion-resistant metal material or alloy to provide corrosion resistance, such as: copper, stainless steel, Nickel-based alloys, etc. Since corrosion-resistant metals are generally more expensive than high-strength metals, unless they are used in some environments that require extremely high strength, the thickness ratio of the outer tube 1 and the inner tube 2 can be controlled at (2-3):1 to ensure a lower...

Embodiment 2

[0057] The anticorrosion method of metal pipe in embodiment one, comprises the steps:

[0058] Step A: First polish the surface of the inner and outer tubes, then immerse in a medium-alkaline degreaser for 25 minutes, take it out, rinse it with clean water, and dry it. The degreaser includes 14 parts of sodium hydroxide, 7 parts of sodium phosphate, 7 parts of sodium carbonate, 2 parts of sodium silicate, 100 parts of water;

[0059] Step B: Shot blasting the inner and outer pipes to Sa2.5 level, and the surface roughness is controlled at 50 μm;

[0060] Step C: Use a spraying machine to spray water-based zinc-rich paint on the surface of the inner tube and the outer tube, the compression ratio is 65:1, the intake pressure is 0.3MPa, the ambient temperature is ≥10°C, and the relative air humidity is ≤85%;

[0061] Step D: Spray a sealer paint, dry for 3 hours, and the dry film thickness is 20 μm, so that it can completely penetrate into the primer;

[0062] Step E: Spray two...

Embodiment 3

[0085] The anticorrosion method of metal pipe in embodiment one, comprises the steps:

[0086] Step A: First polish the surface of the inner and outer tubes, then immerse in a medium-alkaline degreaser for 20 minutes, take it out, rinse it with clean water, and dry it. The degreaser includes 14 parts of sodium hydroxide, 7 parts of sodium phosphate, 7 parts of sodium carbonate, 2 parts of sodium silicate, 100 parts of water;

[0087] Step B: Shot blasting the inner and outer pipes to Sa2.5 level, and the surface roughness is controlled at 40 μm;

[0088] Step C: Use a spraying machine to spray water-based zinc-rich paint on the surface of the inner tube and the outer tube, the compression ratio is 65:1, the intake pressure is 0.28MPa, the ambient temperature is ≥10°C, and the relative air humidity is ≤85%;

[0089] Step D: Spray a sealer paint, dry for 2 hours, and the dry film thickness is 15 μm, so that it can completely penetrate into the primer;

[0090] Step E: Spray tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com