Flue gas recirculating system based on bypass heat exchanger

A recirculation system and recirculation technology, applied in feed water heaters, preheating, exhaust gas devices, etc., can solve the problems of complicated outlet temperature adjustment, and achieve the effect of effectively controlling the furnace temperature level and suppressing or preventing furnace coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

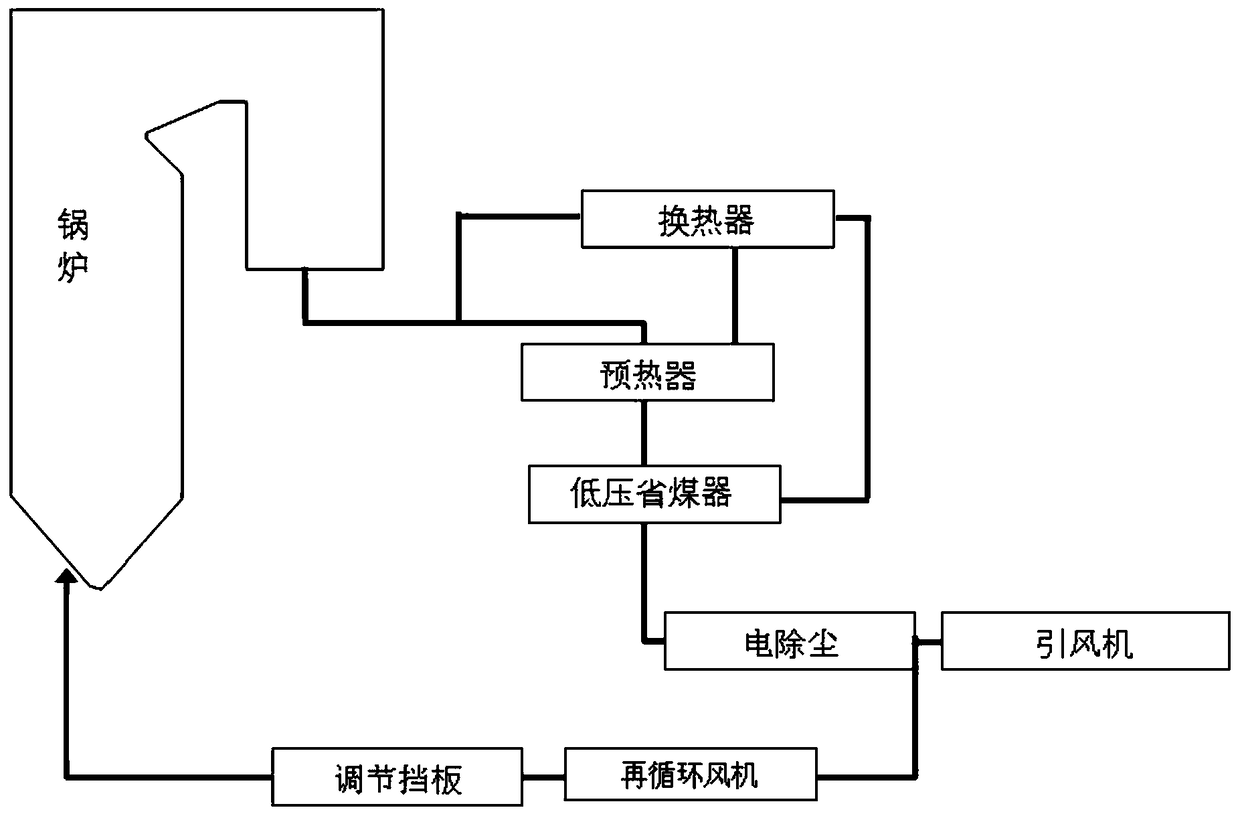

[0021] Such as figure 1 As mentioned above, the flue gas recirculation system based on the bypass heat exchanger in this embodiment includes: a main flue is connected to the flue gas outlet of the boiler, and a preheater and a low-pressure economizer are sequentially arranged on the flue gas main pipe , electrostatic precipitator, induced draft fan, the flue gas main pipe behind the electric precipitator is connected with a recirculation flue, and the recirculation flue is connected to the boiler furnace, at the air inlet of the recirculation fan to the boiler furnace The recirculation flue between them is equipped with an adjusting baffle device, the preheater is provided with a cooling bypass, and a heat exchanger is installed on the cooling bypass, and the heat exchange working fluid of the heat exchanger adopts the unit The low-pressure economizer system exports low-temperature flue gas.

[0022] In this embodiment, the cold flue gas is exchanged with the flue gas after u...

Embodiment 2

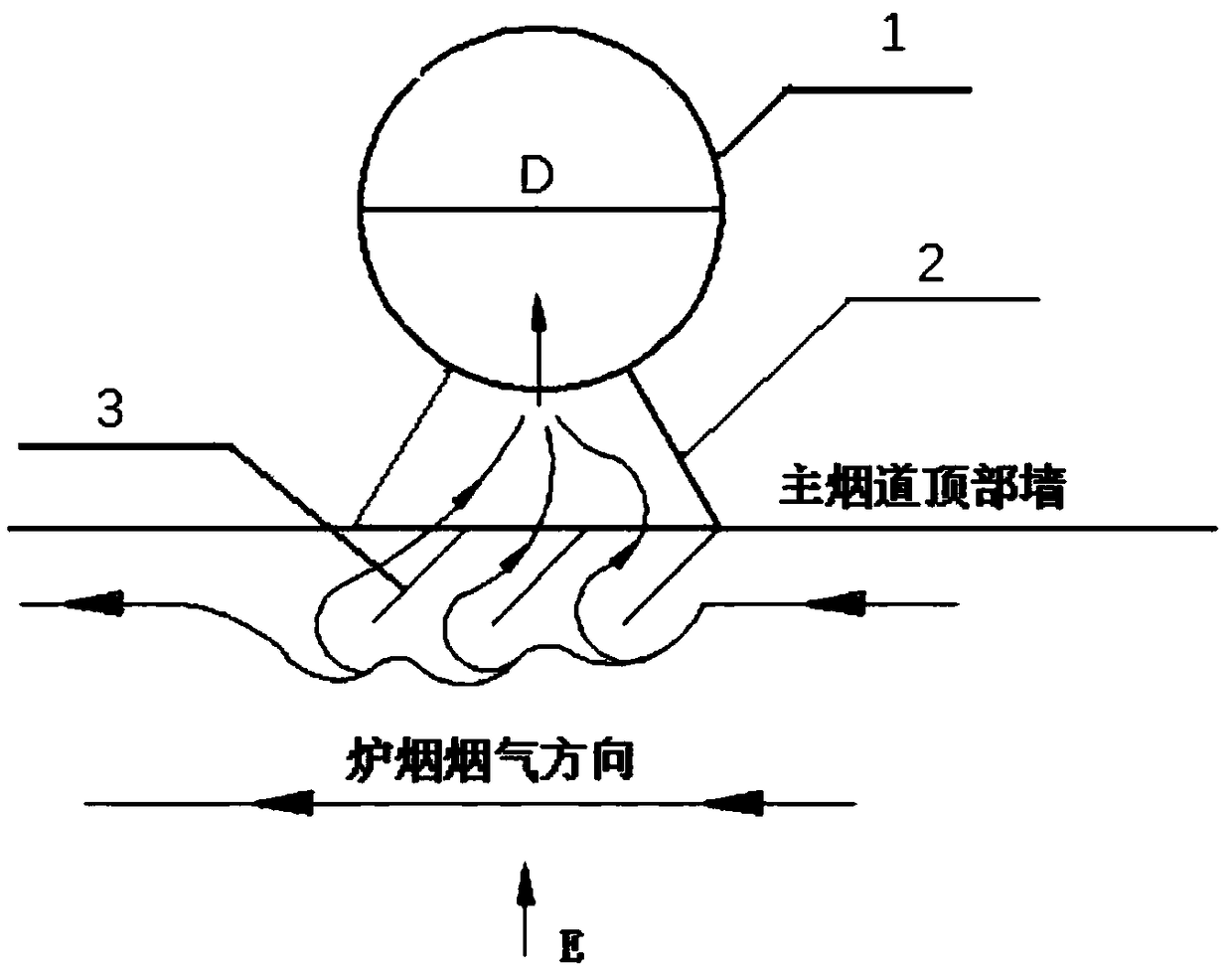

[0025] This embodiment is based on the flue gas recirculation system of the bypass heat exchanger. On the basis of Embodiment 1, the recirculation fan is a centrifugal or axial flow fan, and 4 recirculation fans are provided. Each recirculation fan The flue gas extracted separately is sent to the lower four corners of the boiler furnace respectively.

[0026] In this embodiment, the recirculated flue gas directly enters the flue gas recirculation fan, and then is sent to the lower four corners of the boiler furnace. In order to increase the flexibility of flue gas regulation, Anyuan Project has installed four 30% capacity centrifugal furnace fume fans, all of which are controlled by frequency conversion.

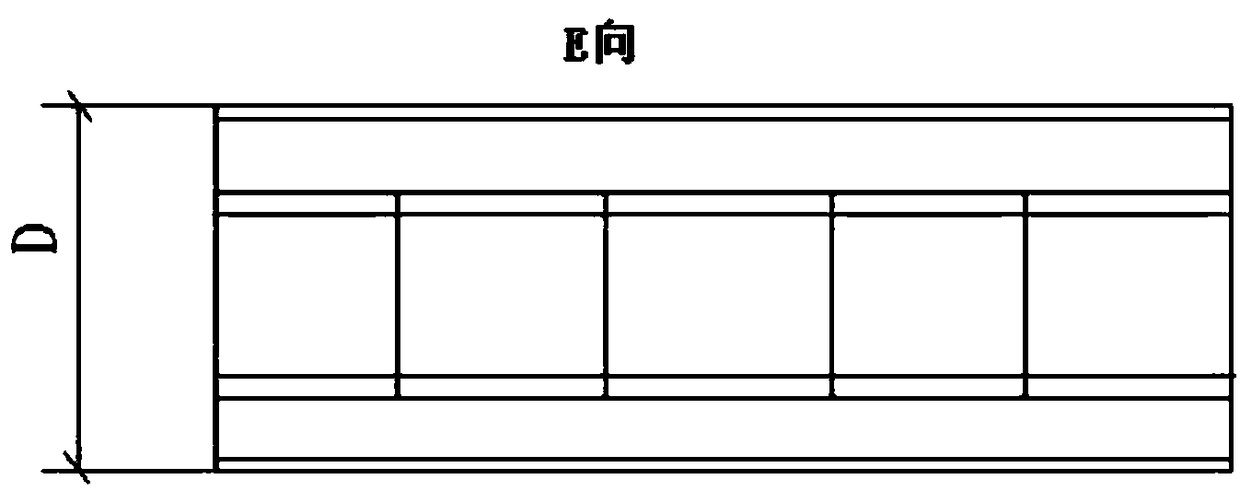

[0027] The flow medium of the flue gas recirculation fan is a high-temperature and high-dust medium. The mechanism of wear is the erosion and wear of materials caused by dust being entrained in the airflow and impacting the wall under its own inertia. In the outlet area of ...

Embodiment 3

[0029] This example is based on the flue gas recirculation system of the bypass heat exchanger. On the basis of Example 1, the flue gas recirculation fan adopts the following combined anti-wear technical measures:

[0030] Low-speed fans are used, and the fan speed does not exceed 1000rpm.

[0031] The impeller and casing are cast with new wear-resistant alloy, the impeller is integrally cast, and the upper part of the casing is equipped with a wear-resistant composite plate.

[0032] The surface of the impeller is made of new surfacing and wear-resistant Fe-05 material.

[0033] The new technology of fan flow field design (such as three-dimensional flow) is adopted to further optimize the fan flow field and improve the overall wear resistance.

[0034] After adopting the above-mentioned anti-wear technical measures, the continuous operation period of the fan can reach more than 2 years, which fully meets the maintenance and operation requirements of thermal power plants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com