Catalyst for preparing tetrahydronaphthalene through selective catalytic naphthaline hydrogenation and preparation method and application thereof

A technology for selective and catalytic hydrogenation of naphthalene, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Harsh nickel preparation conditions, expensive precious metals and other problems, to achieve the effect of high value-added utilization, simple preparation method, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042]The preparation method of the above-mentioned catalyst is as follows: the active component is loaded on the catalyst carrier by an equal-volume impregnation method, the catalyst is obtained by ultrasonication, standing still, drying and then roasting; wherein, the roasting temperature is 400-600°C. Preferably, the firing temperature is 450-550°C.

[0043] When the active component is two kinds of Co, Mo, Ni and W, the loading method is one-step impregnation loading or step-by-step impregnation loading, preferably one-step impregnation loading.

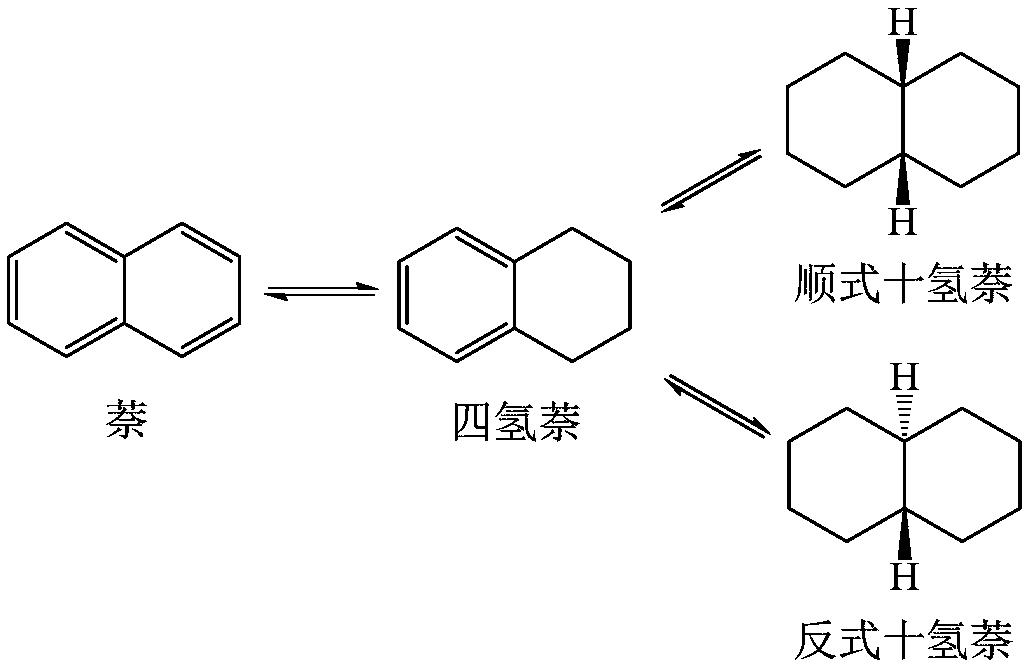

[0044] see figure 1 , the application of the catalyst in the reaction of preparing tetrahydronaphthalene by selective hydrogenation of naphthalene. The initial H of the reaction 2 The pressure is 2-10MPa, the reaction temperature is 160-240°C, and the reaction time is 2-10h.

[0045] Preferably, the initial H of the reaction 2 The pressure is 6-8MPa, the reaction temperature is 180-220°C, and the reaction time is 6-8h.

[00...

Embodiment 1

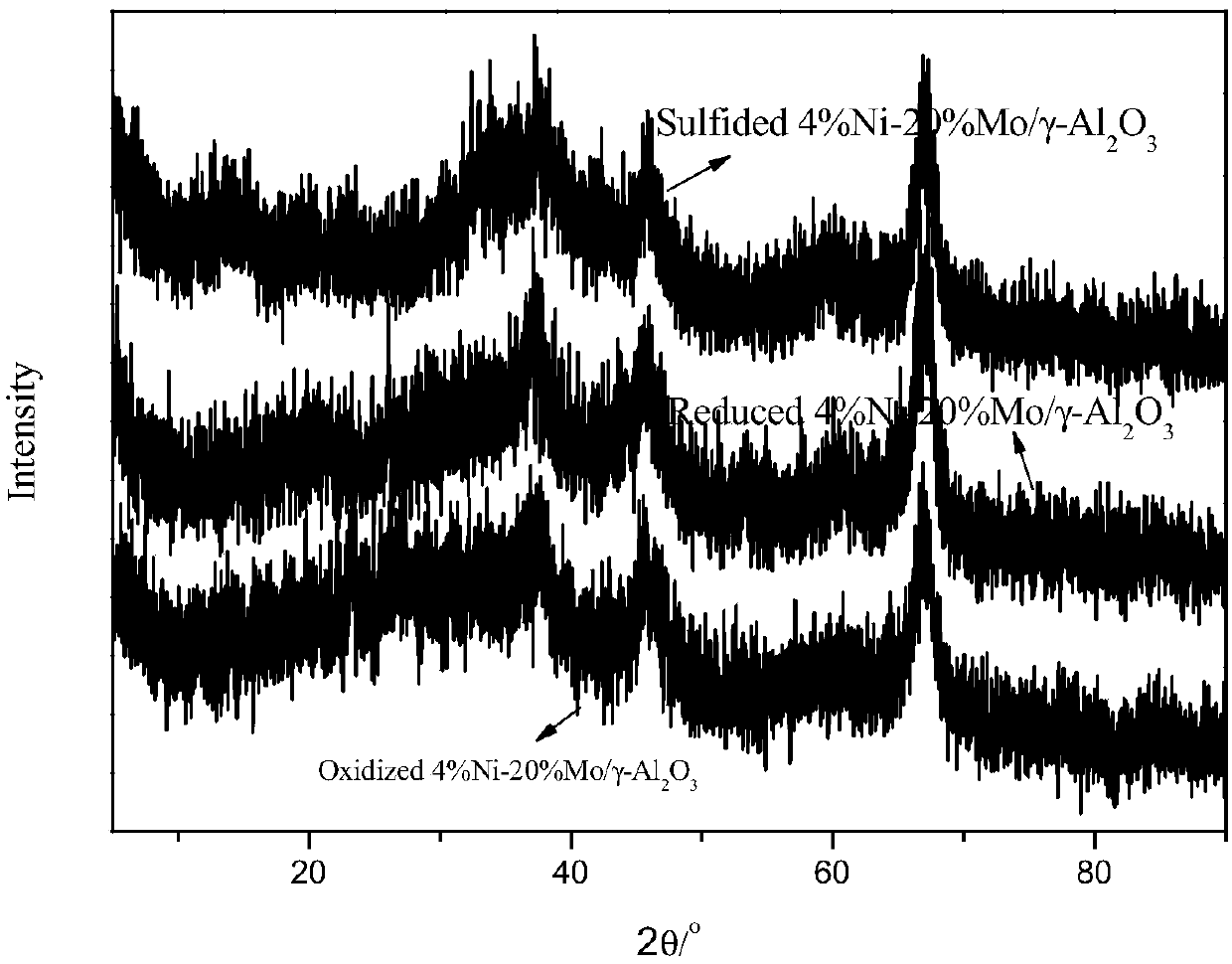

[0049] 4% NiO loading, MoO 3 Oxidation state NiO-MoO with a loading of 20% 3 / γ-Al 2 o 3 Preparation: Using the equal volume impregnation method, a certain amount of Ni salt (NiNO 3 ·6H 2 O) and Mo salt ((NH 4 ) 6 Mo 7 o 24 4H 2 O) adding a certain amount of distilled water to form a solution; dipping in γ-Al 2 o 3 On the carrier, after stirring evenly, ultrasonic for half an hour, let stand at room temperature for 12h; then dry at 120°C for 4h, and bake at 500°C for 4h; the oxidation state 4%NiO-20%MoO can be obtained 3 / γ-Al 2 o 3 .

Embodiment 2

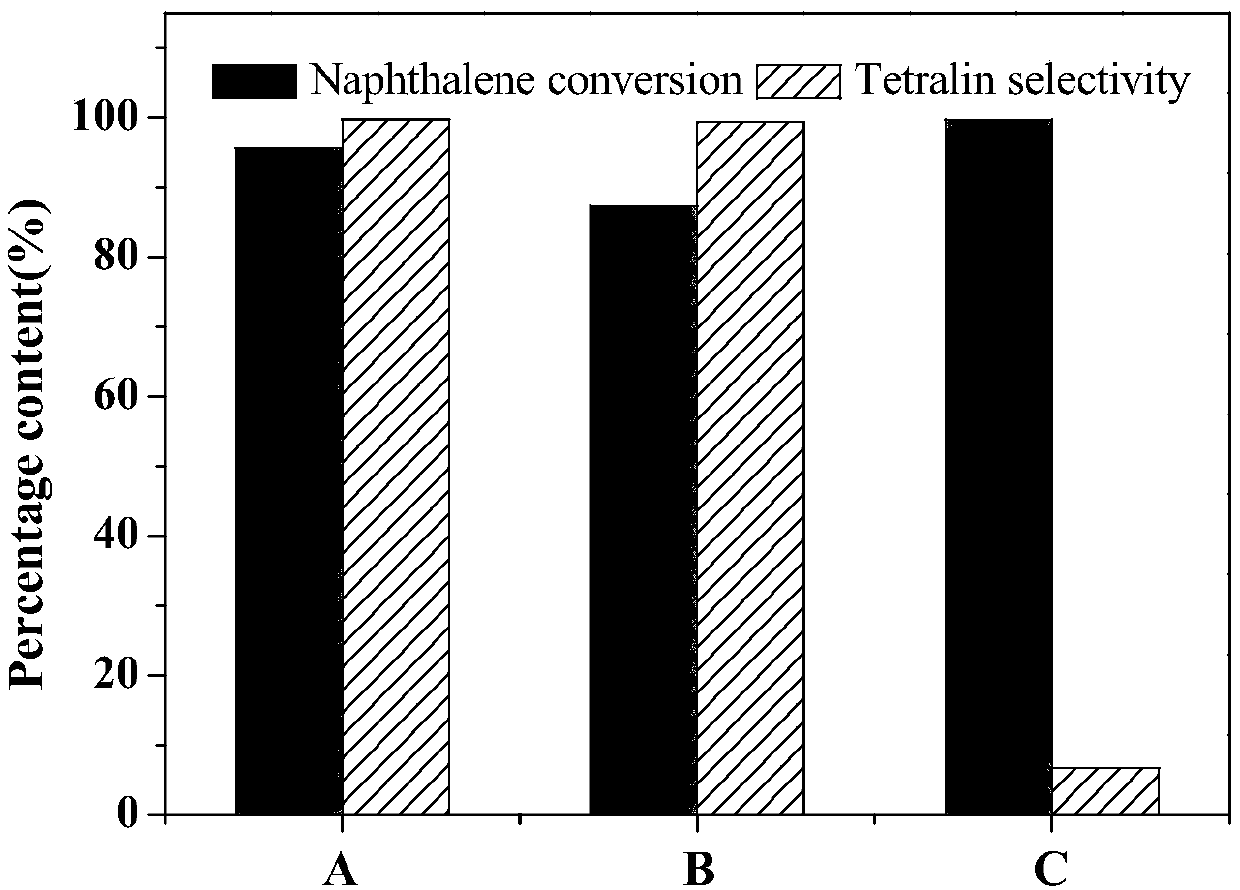

[0057] A catalyst with a nickel-molybdenum loading of 12% was prepared by one-step impregnation (the mass ratio of nickel oxide to molybdenum oxide was 1:5).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com