A method for preparing high-purity silicon nitride powder by liquid-phase assisted combustion synthesis

A silicon nitride powder, auxiliary combustion technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of impurity residues and harm to the health of producers, and achieve high production efficiency, energy saving, and rapid synthesis reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh raw materials according to weight ratio: 200 mesh silicon powder is 30%, and silicon nitride (average particle size 2 μm) is 70%.

[0030] (2) After mixing the raw materials with alcohol, use silicon nitride balls as the medium, ball mill on a rolling ball mill for 1 hour, and then vacuum dry at 80°C.

[0031] (3) Mix the dried raw material powder with alcohol that accounts for 20% of the weight ratio of the raw material powder in a high-speed mixer. Then mix for 1 min.

[0032] (4) The raw material powder is directly loaded into a porous graphite boat and placed in a combustion synthesis device. After vacuuming, fill it with 1MPa high-purity nitrogen. Use titanium powder as the ignition agent to induce combustion synthesis reaction. After the combustion reaction is over, the gas in the device is released, and at the same time, when the circulating water is cooled to below 40°C, the door of the chamber is opened to take out the reaction product.

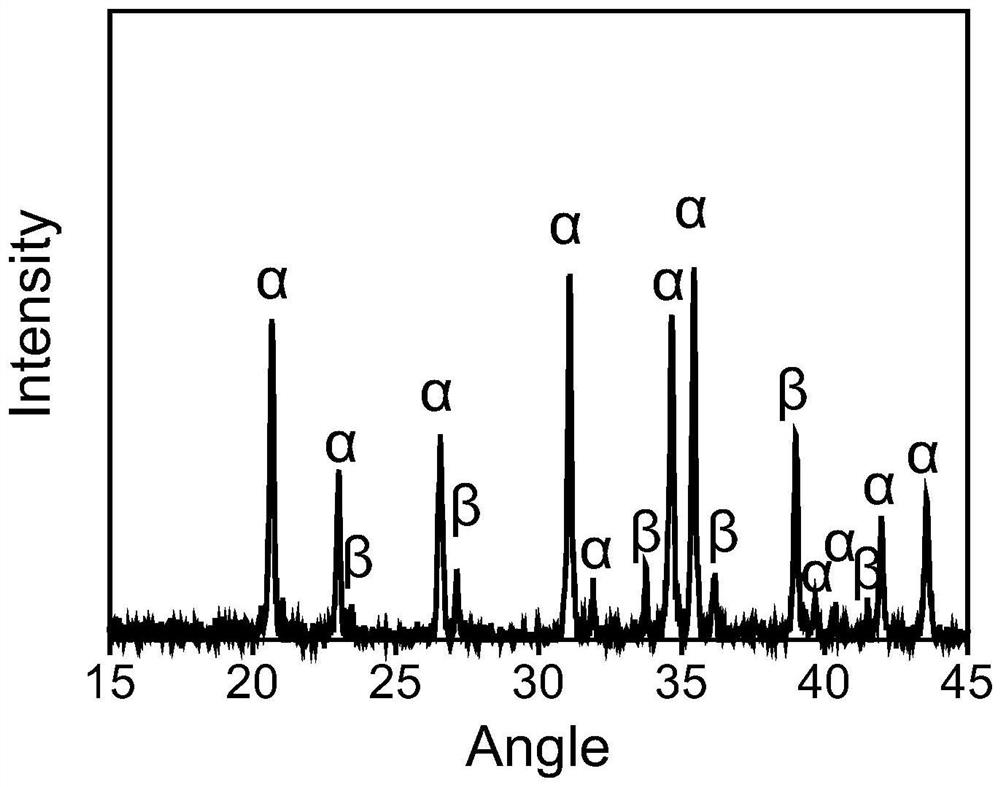

[0033] T...

Embodiment 2

[0035] (1) Weigh raw materials according to weight ratio: 200 mesh silicon powder is 70%, silicon nitride (average particle size 2 μm) is 30%.

[0036] (2) After the raw materials are mixed with alcohol, they are ball-milled on a rolling ball mill for 1 h with silicon nitride balls as the medium, and then vacuum-dried at 80°C.

[0037] (3) Mix the dried raw material powder with 0.5% alcohol in the weight ratio of the raw material powder in a high-speed mixer. During the mixing process, the alcohol is added to the raw material at one time and mixed for 5 minutes.

[0038] (3) The raw material powder is directly loaded into a porous graphite boat and placed in a combustion synthesis device. After vacuuming, fill it with 4.5MPa high-purity nitrogen. Use titanium powder as the ignition agent to induce combustion synthesis reaction. After the combustion reaction is over, the gas in the device is released, and at the same time, when the circulating water is cooled to below 40°C, t...

Embodiment 3

[0041] (1) Weigh raw materials according to weight ratio: 100 mesh silicon powder is 50%, silicon nitride (average particle size 2 μm) is 50%.

[0042] (2) After the raw materials are mixed with alcohol, they are ball-milled on a rolling ball mill for 1 h with silicon nitride balls as the medium, and then vacuum-dried at 80°C.

[0043] (3) Mix the dried raw material powder with 10% alcohol in a high-speed mixer in the weight ratio of the raw material powder. During the mixing process, the alcohol is mixed into the raw material in a small amount and multiple times. 1min.

[0044] (4) The raw material powder is directly loaded into a porous graphite boat and placed in a combustion synthesis device. After vacuuming, fill it with 1MPa high-purity nitrogen. Use titanium powder as the ignition agent to induce combustion synthesis reaction. After the combustion reaction is over, the gas in the device is released, and at the same time, when the circulating water is cooled to below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com