Method for preparing high-purity polymerization-grade crystallized lactic acid

A polymerization-grade, high-purity technology, applied in the field of chemical production, can solve problems such as unreachable, high separation effect, and difficult effective separation, so as to improve product quality, optimize the preparation process, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

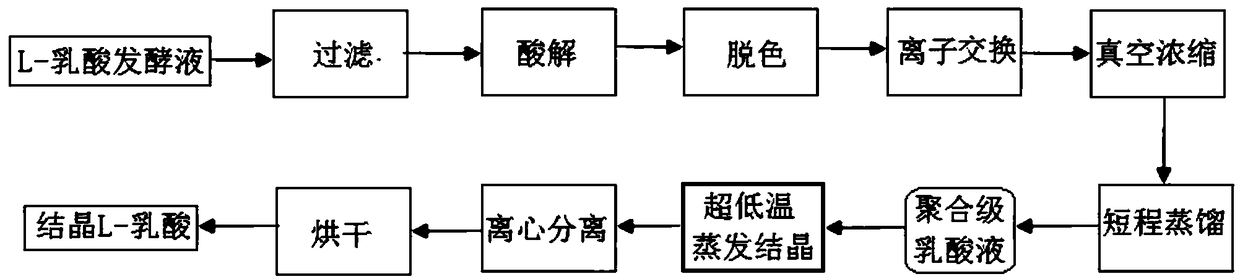

[0011] The present invention prepares the process of high-purity polymerization grade crystalline lactic acid such as figure 1 As shown, the process is as follows: the L-lactic acid fermentation broth is filtered, acidolyzed, activated carbon decolorized, ion exchange resin treated, vacuum concentrated and refined by short-path distillation to obtain a polymer grade lactic acid liquid with a purity of 90% (weight). Acidolysis is carried out with dilute sulfuric acid with a concentration of 5% (weight), and the conditions for acidolysis are temperature 75-85° C. and normal pressure. The decolorization is that the filtrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com