Anti-corrosion high-intensity natural gas pipeline corrosion prevention paint

A technology for natural gas pipelines and anti-corrosion coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems that affect the anti-corrosion effect of coatings on natural gas pipelines, complex raw materials and processes, and corrosion of the outer wall of the pipeline, so as to facilitate uniform coating and film formation, and improve Flexibility, corrosion inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

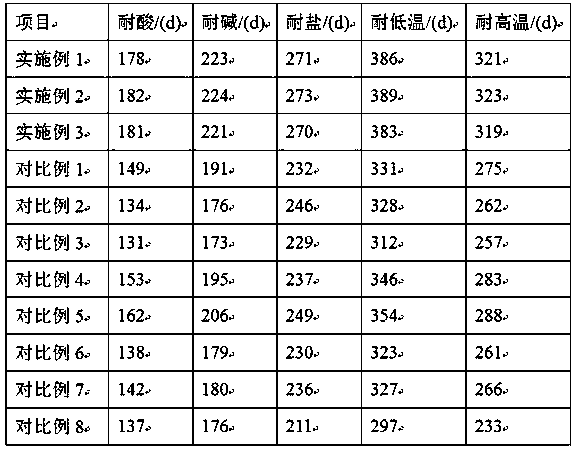

Examples

Embodiment 1

[0018] A corrosion-resistant high-strength anticorrosion coating for natural gas pipelines, made of the following raw materials in parts by weight: polyvinyl acetate emulsion 42, modified polyvinyl chloride resin 35, activated carbon fiber 6, sodium methyl silicate 4, fatty acid methyl ester 3, Titanium dioxide 1.1.

[0019] For the modified polyvinyl chloride resin, heat the polyvinyl chloride resin to 90°C, stir until it is completely melted, add 1.3% thiourea by weight of the polyvinyl chloride resin, keep stirring for 30 minutes, and cool down to normal temperature at 2°C / min. Make the polyvinyl chloride resin and thiourea fully branched, improve the fluidity and flexibility of the polyvinyl chloride resin, facilitate the close combination of the coating and the natural gas pipeline, and carry out comprehensive anti-corrosion protection on the natural gas pipeline, and obtain the modified polyvinyl chloride resin.

[0020] A method for preparing a corrosion-resistant high-...

Embodiment 2

[0028] A corrosion-resistant high-strength anticorrosion coating for natural gas pipelines, made of the following raw materials in parts by weight: polyvinyl acetate emulsion 43, modified polyvinyl chloride resin 36, activated carbon fiber 7, sodium methyl silicate 5, fatty acid methyl ester 4, Titanium dioxide 1.2.

[0029] For the modified polyvinyl chloride resin, heat the polyvinyl chloride resin to 95°C, stir until it is completely melted, add 1.4% thiourea by weight of the polyvinyl chloride resin, keep stirring for 35 minutes, and cool down to normal temperature at 2.5°C / min. Make the polyvinyl chloride resin and thiourea fully branched, improve the fluidity and flexibility of the polyvinyl chloride resin, facilitate the close combination of the coating and the natural gas pipeline, and carry out comprehensive anti-corrosion protection on the natural gas pipeline, and obtain the modified polyvinyl chloride resin.

[0030] A method for preparing a corrosion-resistant hig...

Embodiment 3

[0038]A corrosion-resistant high-strength anticorrosion coating for natural gas pipelines, made of the following raw materials in parts by weight: polyvinyl acetate emulsion 44, modified polyvinyl chloride resin 37, activated carbon fiber 8, sodium methyl silicate 6, fatty acid methyl ester 5, Titanium dioxide 1.3.

[0039] For the modified polyvinyl chloride resin, heat the polyvinyl chloride resin to 100°C, stir until it is completely melted, add 1.5% thiourea by weight of the polyvinyl chloride resin, keep stirring for 40 minutes, and cool down to normal temperature at 3°C / min. Make the polyvinyl chloride resin and thiourea fully branched, improve the fluidity and flexibility of the polyvinyl chloride resin, facilitate the close combination of the coating and the natural gas pipeline, and carry out comprehensive anti-corrosion protection on the natural gas pipeline, and obtain the modified polyvinyl chloride resin.

[0040] A method for preparing a corrosion-resistant high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com