Magnetic memory alloy with large strain and preparation method thereof

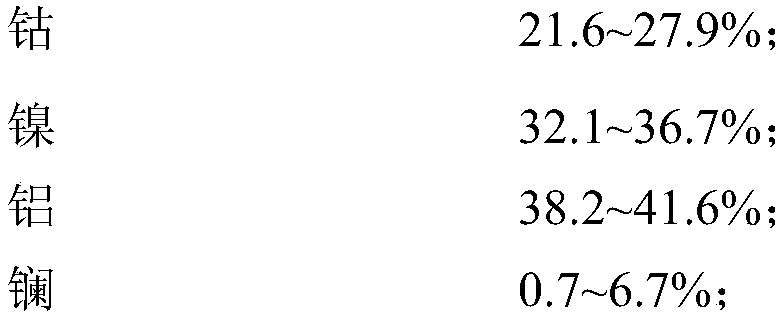

A technology of memory alloy and large strain, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc. It can solve the problem that magnetic shape memory alloys have not made obvious breakthroughs, hinder the application and promotion of alloys, and have unsatisfactory repeatability and other issues, to achieve the effect of broadening the scope of industrial applications, excellent mechanical properties, and large magnetic strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

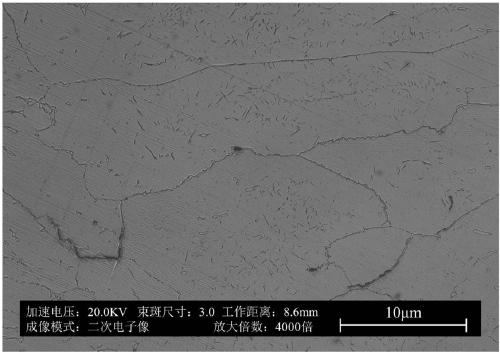

Image

Examples

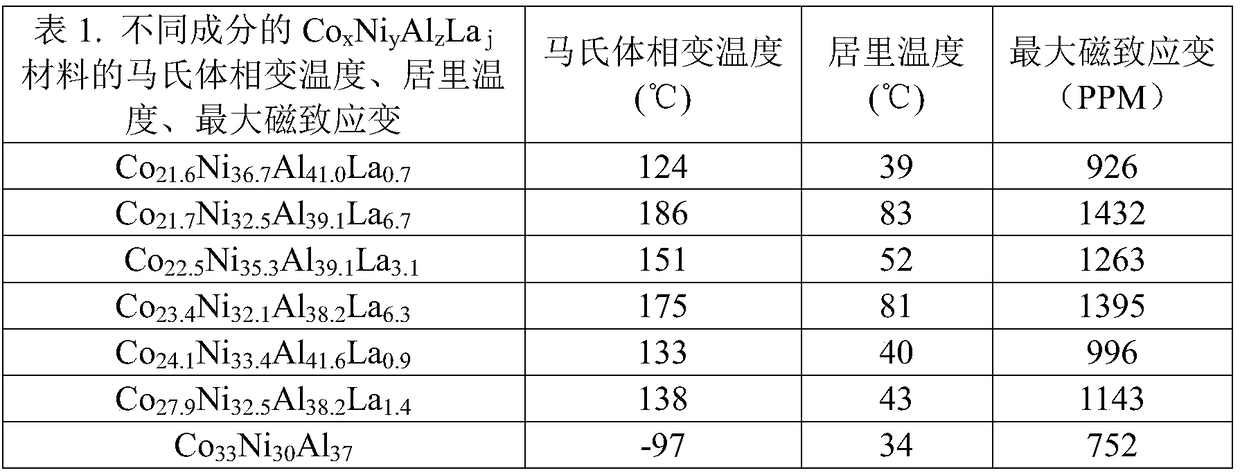

Embodiment 1

[0026] Prepare 500g composition as Co 21.6 Ni 36.7 al 41.0 La 0.7 A magnetic memory alloy with large strain, its preparation method is as follows:

[0027] S1. Ingredients: Weigh Co, Ni, Al, La with a purity of 99.99% respectively;

[0028] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, the melting conditions are: a.5×10 -2 The low vacuum state of MPa; b. the smelting temperature is 1450 ℃; c. the smelting process adopts magnetic stirring; d. the smelting time is 335s (according to the formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 15s g -1 / 2 , M is 500g);

[0029] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum melting is subjected to vacuum magnetic field heat treatment, the treatment conditions are: temperature 655°C; time: 6 hours; vacuum degree: 1×10 -3 MPa; Applied magnetic field strength: 5×10 5 A·m -1 ; Magnetic field rise rate: 500A·m -1 ·s -1 ;

[0030] S4. Cooling: then c...

Embodiment 2

[0033] Prepare 800g composition as Co 21.7 Ni 32.5 al 39.1 La 6.7 A magnetic memory alloy with large strain, its preparation method is as follows:

[0034] S1. Ingredients: Weigh Co, Ni, Al, La with a purity of 99.99% respectively;

[0035] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, the melting conditions are: a.8×10 -2 The low vacuum state of MPa; b. melting temperature is 1480 ℃; c. melting process adopts magnetic stirring; d. melting time is 368s (according to formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 13s g -1 / 2 , M is 800g);

[0036] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum melting is subjected to vacuum magnetic field heat treatment, the treatment conditions are: temperature 670°C; time: 5.5 hours; vacuum degree: 7×10 -2 MPa; Applied magnetic field strength: 6×10 5 A·m -1 ; Magnetic field rise rate: 500A·m -1 ·s -1 ;

[0037] S4. Cooling: followed by furnace coo...

Embodiment 3

[0040] Prepare 400g composition as Co 22.5 Ni 35.3 al 39.1 La 3.1 A magnetic memory alloy with large strain, its preparation method is as follows:

[0041] S1. Ingredients: Weigh Co, Ni, Al, La with a purity of 99.99% respectively;

[0042] S2. Melting: Put the prepared raw materials in a crucible for vacuum melting, and the melting conditions are: a.9×10 -2 The low vacuum state of MPa; b. the smelting temperature is 1500 ℃; c. the smelting process adopts magnetic stirring; d. the smelting time is 240s (according to the formula t=K×(M -1 / 2 ) to obtain, where the element coefficient K is 12s g -1 / 2 , M is 400g);

[0043] S3. Magnetic field heat treatment: The alloy ingot obtained by the above vacuum melting is subjected to vacuum magnetic field heat treatment, the treatment conditions are: temperature 680°C; time: 5 hours; vacuum degree: 9×10 -2 MPa; Applied magnetic field strength: 1×10 6 A·m -1 ; Magnetic field rise rate: 500A·m -1 ·s -1 ;

[0044] S4. Cooling: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com