Novel rubber and plastic sports floor and preparation method

A technology for rubber, plastic and flooring, applied in chemical instruments and methods, lamination, building components, etc., can solve the problems of cumbersome production process, high price, not easy to age and service life, etc., and achieve simple and efficient preparation process and easy industrial production. , Overcome the effect of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention provides a new type of rubber and plastic sports floor and its preparation method. The present invention will be further described below in combination with specific embodiments.

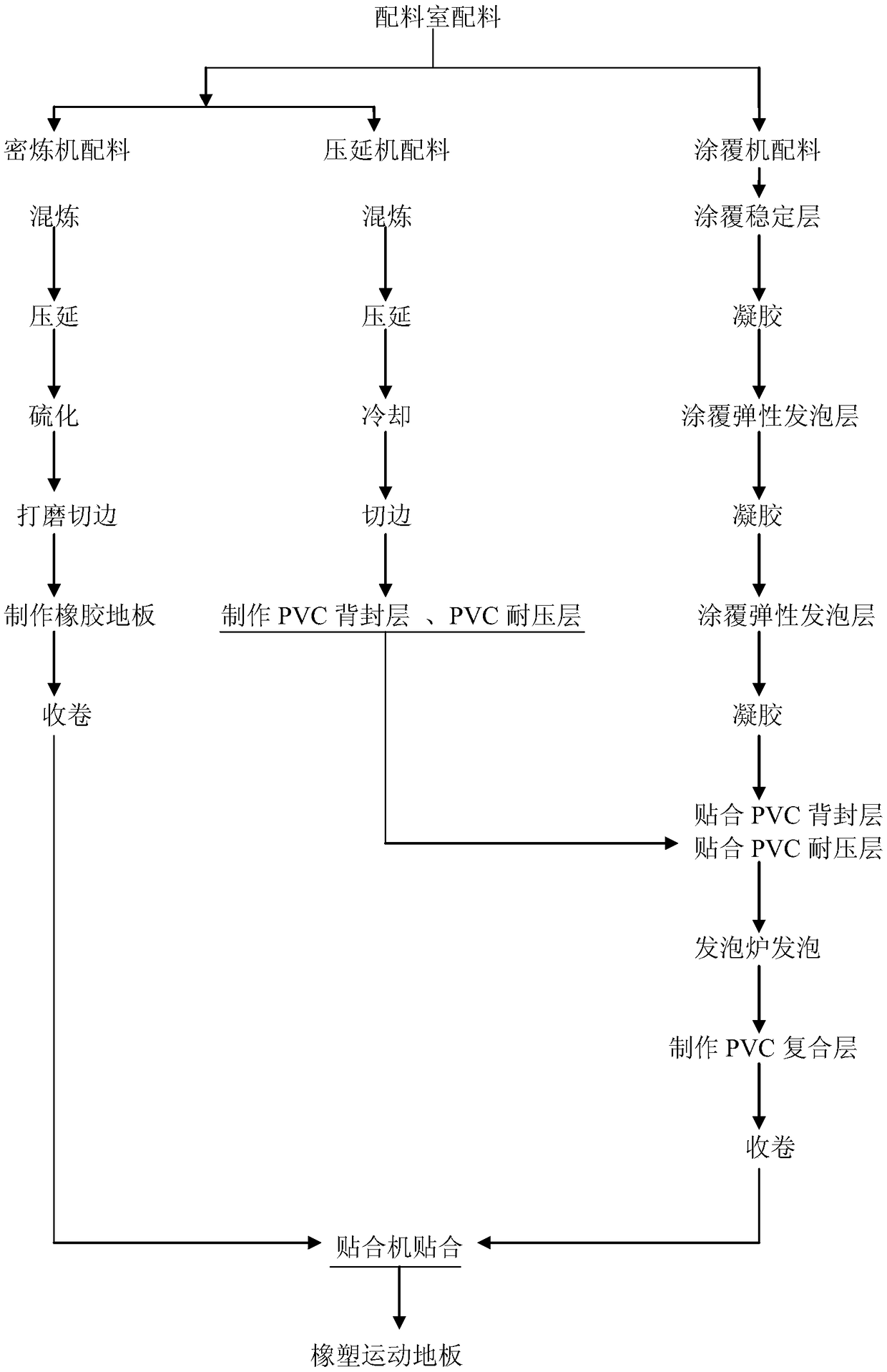

[0024] according to figure 1 The process flow chart shown in the preparation of the new rubber and plastic sports floor includes the following steps:

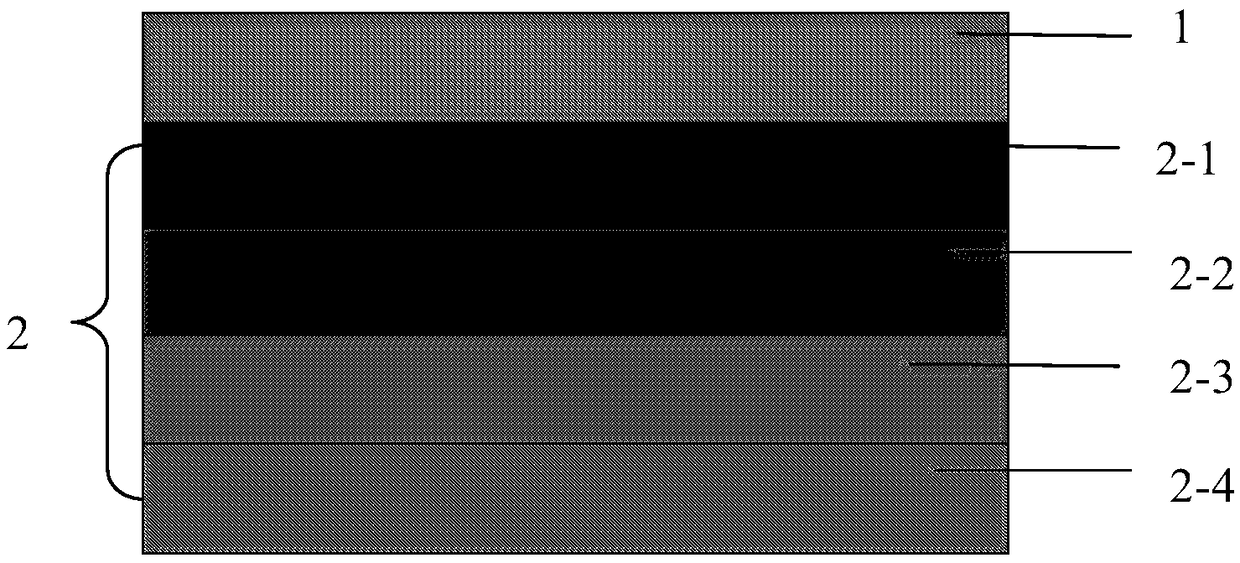

[0025] (1) Preparation of rubber wear-resistant layer 1

[0026] (1.1) According to the mass fraction, put one or more of 95% styrene-butadiene rubber, EPDM rubber, and high-styrene rubber into the internal mixer, soften it for 1.5min, and then put 0.2% zinc oxide, 0.2% stearic acid, 0.2% antioxidant, 0.2% antiaging agent, 0.2% sulfur accelerator, heating at 120°C for 2 minutes, and finally adding 4% of one or more of white carbon black, kaolin, and calcium carbonate as a reinforcing filling material;

[0027] (1.2) Release the pressure, discharge the mixed rubber material and put it in the open mill for 5 minutes, rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com