CeO2/CuO (cerium oxide/copper oxide) heterojunction composite oxide and preparation method and application thereof

A composite oxide, heterojunction technology, applied in chemical instruments and methods, separation methods, instruments, etc., can solve the problems of inaccurate detection results of sensors, poor CuO selectivity, etc., and achieve easy integration and portability, low cost, and preparation. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

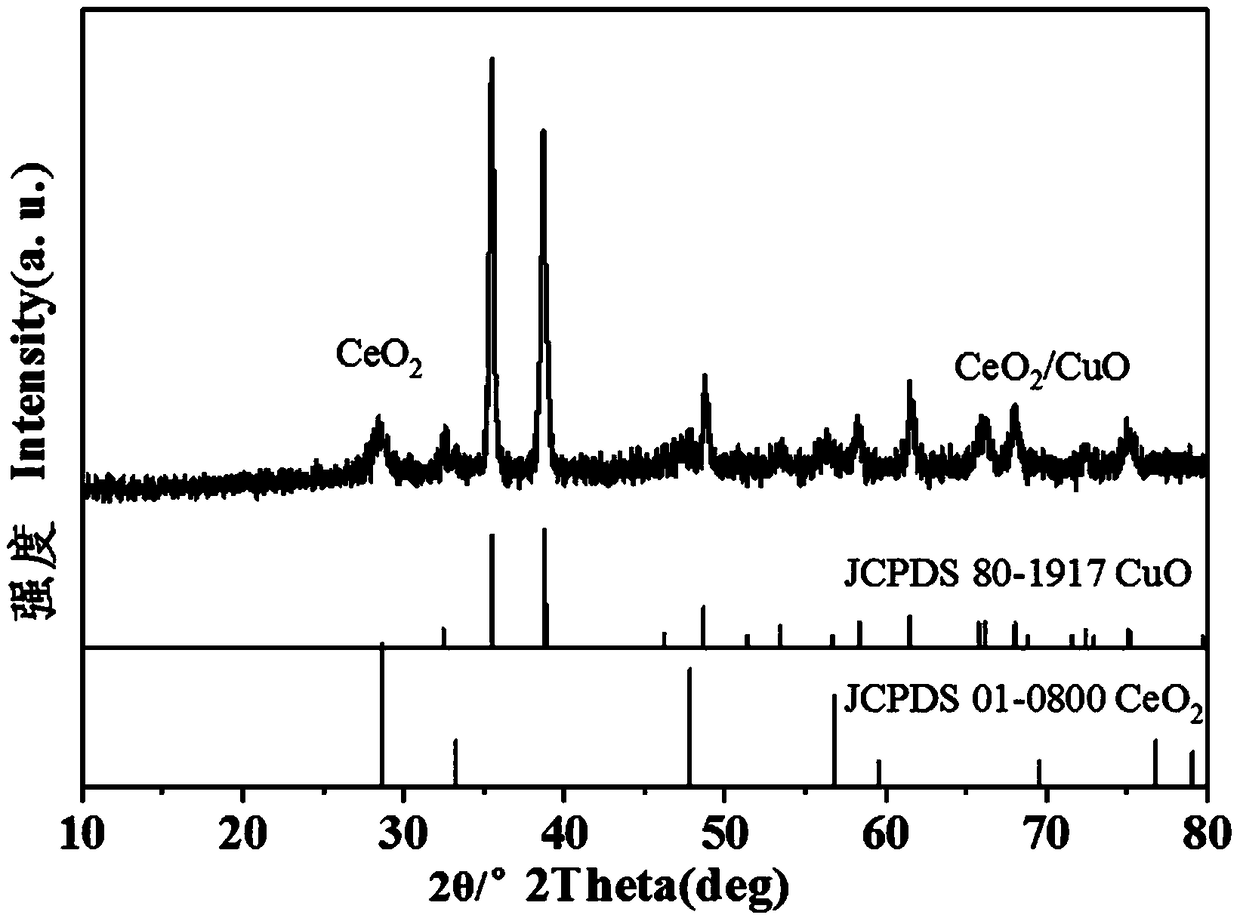

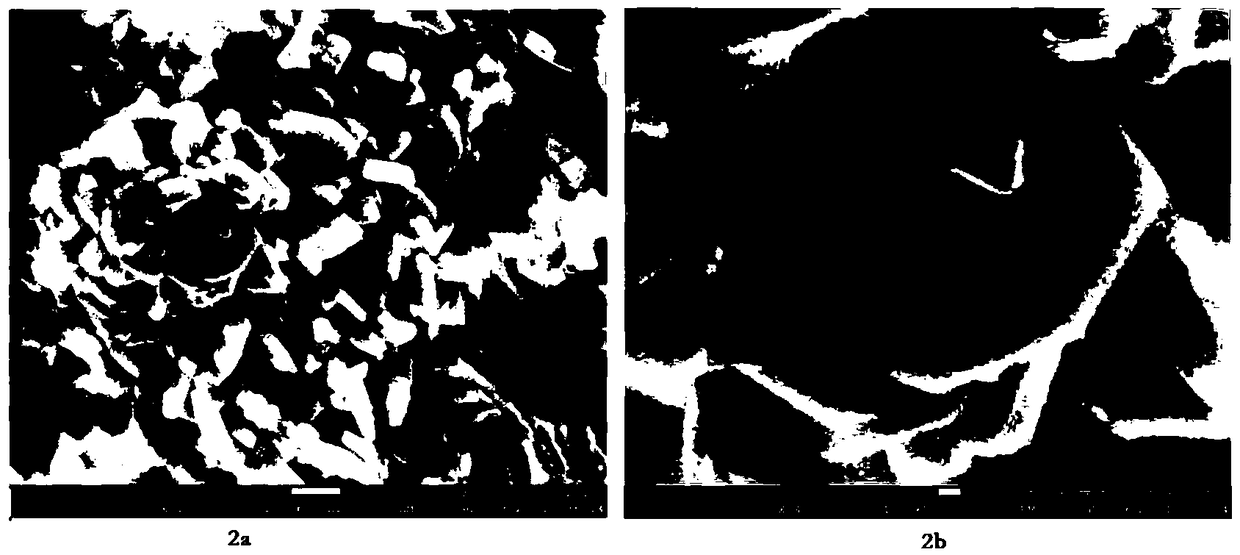

[0057] An embodiment of the present invention provides a cerium oxide / copper oxide heterojunction composite oxide, including a CuO substrate and supported CeO on the surface of the CuO substrate 2 , the chemical formula is: xCeO 2 / yCuO, where x:y=1:10, the particle size is 0.5-2 μm.

[0058] The preparation method of the above-mentioned cerium oxide / copper oxide heterojunction composite oxide comprises the following steps:

[0059] Step a, preparation of CuO substrate

[0060] Weigh 1.8756g of copper nitrate into a 50mL small beaker, add 15mL of deionized water, and then add 10mL of absolute ethanol to dissolve to obtain an aqueous copper nitrate ethanol solution; weigh 0.6006g of urea, add 10mL of deionized water to dissolve to obtain an aqueous urea solution;

[0061] Under magnetic stirring, add urea aqueous solution dropwise to copper nitrate ethanol aqueous solution, ultrasonically treat for 20 minutes, add to a 50mL polytetrafluoroethylene-lined autoclave, and conduct...

Embodiment 2

[0068] An embodiment of the present invention provides a cerium oxide / copper oxide heterojunction composite oxide, including a CuO substrate and supported CeO on the surface of the CuO substrate 2 , the chemical formula is: xCeO 2 / yCuO, where x:y=1.5:9, particle size is 0.5-2 μm.

[0069] The preparation method of the above-mentioned cerium oxide / copper oxide heterojunction composite oxide comprises the following steps:

[0070] Step a, preparation of CuO substrate

[0071] Weigh 2.12g of copper nitrate into a 50mL small beaker, add 10mL of deionized water, and then add 15mL of absolute ethanol to dissolve to obtain an aqueous solution of copper nitrate in ethanol; weigh 0.72g of urea, add 10mL of deionized water to dissolve to obtain an aqueous solution of urea;

[0072] Under magnetic stirring, add urea aqueous solution dropwise to copper nitrate ethanol aqueous solution, ultrasonically treat for 25 minutes, add to a 50mL polytetrafluoroethylene-lined autoclave, and condu...

Embodiment 3

[0079] An embodiment of the present invention provides a cerium oxide / copper oxide heterojunction composite oxide, including a CuO substrate and supported CeO on the surface of the CuO substrate 2 , the chemical formula is: xCeO 2 / yCuO, where x:y=0.8:11, particle size is 0.5-2 μm.

[0080] The preparation method of the above-mentioned cerium oxide / copper oxide heterojunction composite oxide comprises the following steps:

[0081] Step a, preparation of CuO substrate

[0082] Weigh 1.65g of copper nitrate into a 50mL small beaker, add 13mL of deionized water, and then add 12mL of absolute ethanol to dissolve to obtain an aqueous solution of copper nitrate in ethanol; weigh 0.49g of urea, add 10mL of deionized water to dissolve to obtain an aqueous urea solution;

[0083] Under magnetic stirring, add urea aqueous solution dropwise to copper nitrate ethanol aqueous solution, ultrasonically treat for 15 minutes, add to a 50mL polytetrafluoroethylene-lined autoclave, and conduct...

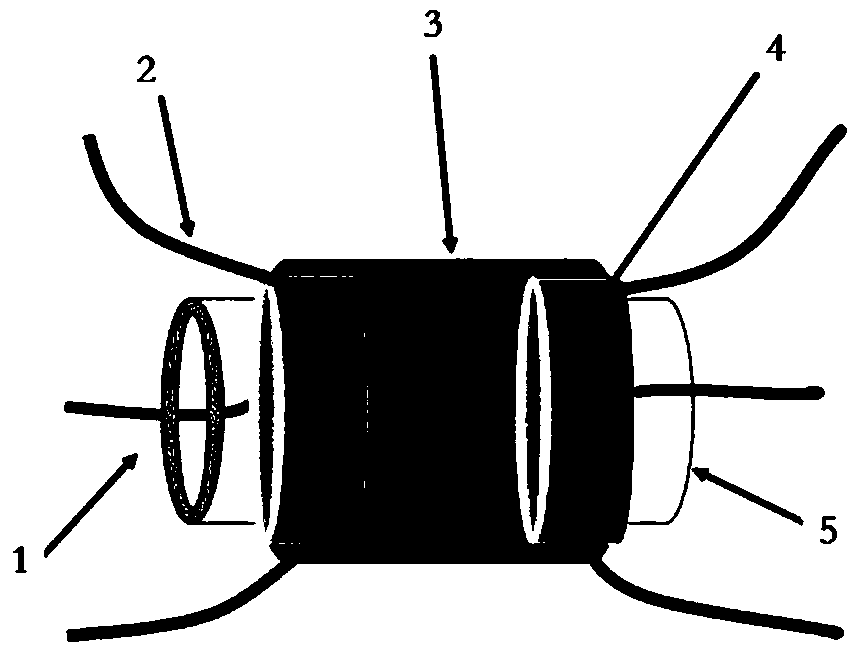

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com