Defect type perovskite photocatalytic material as well as preparation method and application thereof

A photocatalytic material and defect-type technology, which is applied in the field of photocatalytic materials, can solve the problems of high cost, many steps in the preparation method, and the inability to prepare photocatalytic materials, and achieve the effects of high cost, high catalytic activity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

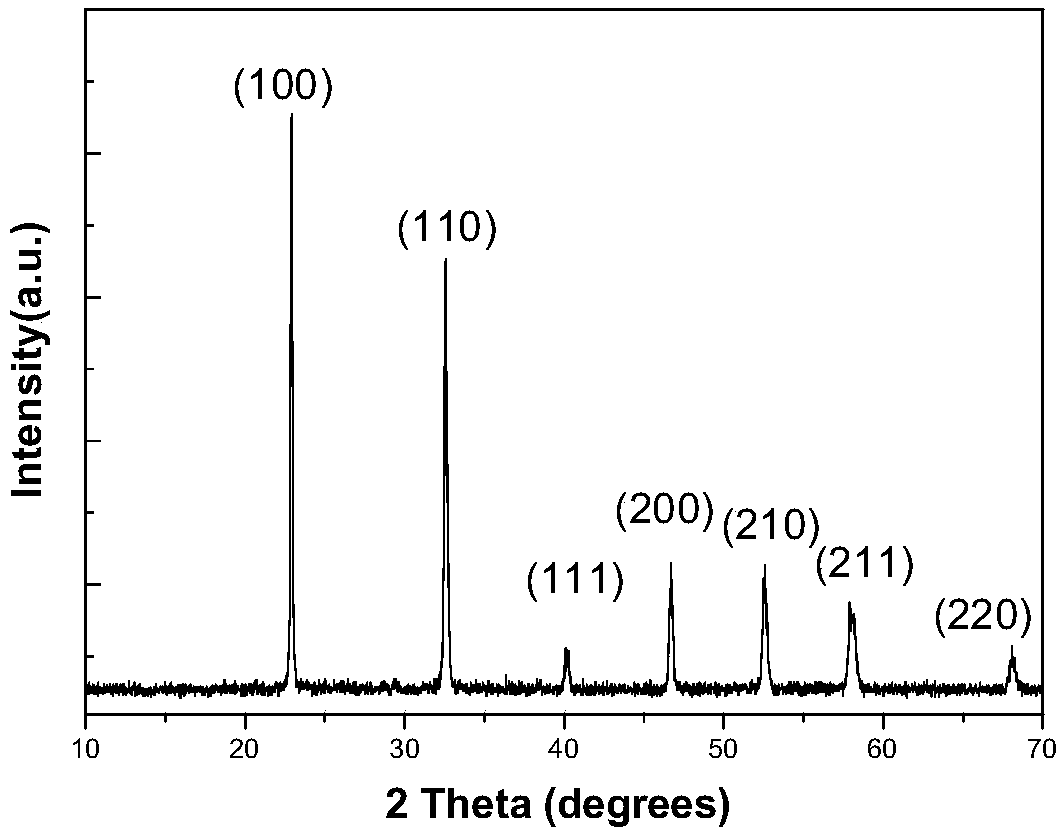

[0029] This embodiment relates to a method for preparing a defect-type perovskite photocatalytic material, comprising the following steps:

[0030] 0.884g Ta 2 o 5 and 1.8g NaF were added to a 100ml hydrothermal reaction kettle, then 1g KOH was added, and finally 70ml NH 3 ·H 2 O, after stirring for 30 minutes, seal the reaction kettle, place it in a blast oven, and react at 270°C for 12 hours. After the reaction system was cooled to room temperature, it was allowed to stand until it was precipitated and separated, centrifuged, and washed with deionized water to neutrality. The product was dried in a blast oven at 80°C for 24 hours to obtain a gray-blue powder defect NaTaO 3 photocatalytic material.

Embodiment 2

[0032] 8.84g Ta 2 o 5 and 5.4g NaF were added to a 100ml hydrothermal reaction kettle, then 1g KOH was added, and finally 70ml NH 3 ·H 2 O, after stirring for 30 minutes, seal the reaction vessel, place it in a blast oven, and react for 24 hours at 270°C. After the reaction system was cooled to room temperature, it was allowed to stand until it was precipitated and separated, centrifuged, and washed with deionized water to neutrality. The product was dried in a blast oven at 80°C for 24 hours to obtain a gray-blue powder defect NaTaO 3 photocatalytic material.

Embodiment 3

[0034] 1.140g Ta(OH) 5 and 1.8g NaF were added to a 100ml hydrothermal reaction kettle, then 1g KOH was added, and finally 70ml NH 3 ·H 2 O, after stirring for 30 minutes, seal the reaction kettle, place it in a blast oven, and react for 24 hours at 220°C. After the reaction system was cooled to room temperature, it was allowed to stand until it was precipitated and separated, centrifuged, and washed with deionized water to neutrality. The product was dried in a blast oven at 80°C for 24 hours to obtain a gray-blue powder defect NaTaO 3 photocatalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com