Method for synthesizing stannum strontium hydroxide nanorod by adopting room temperature solid-phase chemical method

A room temperature solid phase, nanorod technology, applied in chemical instruments and methods, inorganic chemistry, tin compounds, etc., can solve the problems of increasing experimental safety hazards, cumbersome post-treatment process of high-concentration strong bases, etc., and achieves easy mass production. The effect of low cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

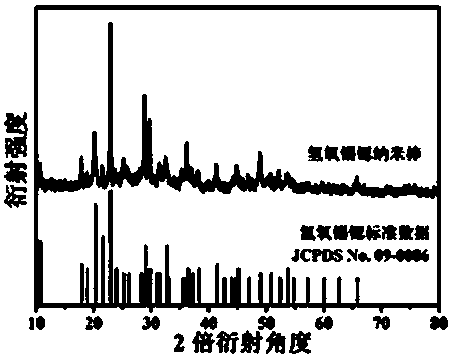

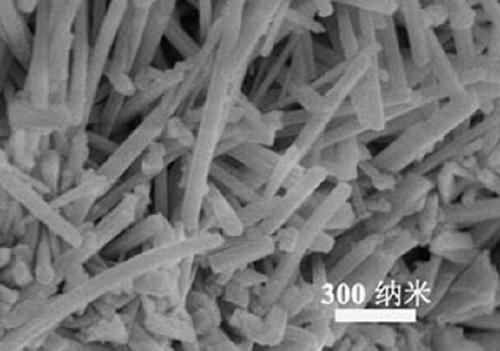

[0012] Accurately weigh 0.01 mole of solid strontium nitrate and place it in an agate mortar to grind finely, then add 0.01 mole of solid tin chloride and grind for 5 minutes, finally add 0.07 mole of sodium hydroxide and grind it quickly, after continuous grinding for 40 minutes, use The sample was washed with ion water and suction filtered to obtain strontium tin hydroxide nanorods.

Embodiment 2

[0014] Accurately weigh 0.01 mole of solid strontium chloride and place it in an agate mortar to grind finely, then add 0.01 mole of solid tin chloride and grind for 5 minutes, and finally add 0.08 mole of sodium hydroxide and grind it quickly. After continuous grinding for 40 minutes, use The samples were washed with deionized water and suction filtered to obtain strontium tin hydroxide nanorods.

Embodiment 3

[0016] Accurately weigh 0.01 mole of solid strontium acetate and grind it into an agate mortar, then add 0.01 mole of solid tin chloride and grind it for 5 minutes, and finally add 0.09 mole of sodium hydroxide and grind it quickly. After continuous grinding for 40 minutes, use The sample was washed with ion water and suction filtered to obtain strontium tin hydroxide nanorods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com