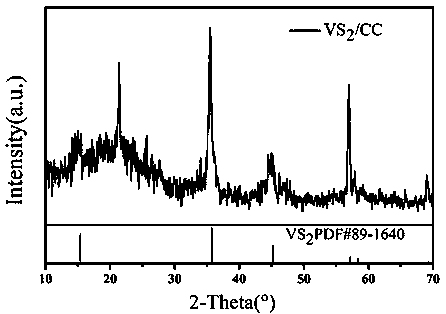

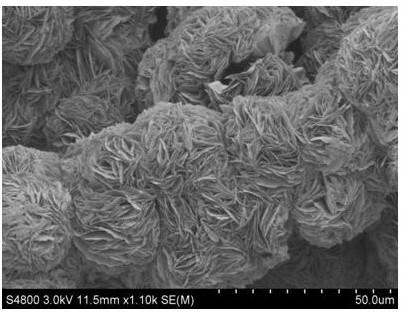

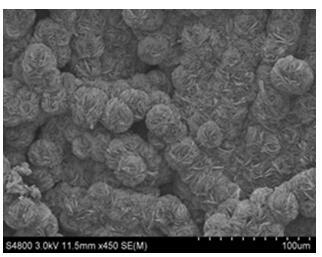

Three-dimensional (3D) multi-stage structure VS2 hydrogen evolution electrocatalyst and preparation method thereof

An electrocatalyst and 3D technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of limited electrode active area, slow diffusion, poor conductivity, etc., and achieve suitable for large-scale production, The effect of low cost and low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Cut the carbon cloth into a rectangle of 1 × 5 cm, activate it by refluxing in concentrated nitric acid at 120 °C for 1 hour, then wash it with ethanol and deionized water for 3 times, and dry it at 50 °C for 8 hours to obtain the treated carbon cloth;

[0022] (2) Weigh Na respectively 3 VO 4 ·12H 2 O, TAA (CH 3 CSNH 2 ) and P123 (PEO 20 PPO 70 PEO 20 ), the molar ratio is 1:4:0.1, dissolved in 25ml of deionized water, the concentration of vanadium source is 0.04mol / L, the concentration of sulfur source is 0.133mol / L, and the concentration of P123 is 0.0033mol / L. Magnetic stirring at room temperature for 40 min to obtain a clear solution;

[0023] (3) Put the carbon cloth treated in (1) into the reaction lining, pour the clear solution obtained in (2), seal it for hydrothermal reaction, set the reaction temperature to 160°C and the reaction time to 18h;

[0024] (4) After the reaction, the reaction kettle was naturally cooled to room temperature, and the ca...

Embodiment 2

[0027] (1) Cut the carbon cloth into a rectangle of 1 × 5 cm, activate it by refluxing in concentrated nitric acid at 80°C for 2 hours, then wash it with ethanol and deionized water for 4 times, and dry it at 50°C for 8 hours to obtain the treated carbon cloth;

[0028] (2) Weigh Na respectively 3 VO 4 ·12H 2 O, TAA (CH 3 CSNH 2 ) and P123 (PEO 20 PPO 70 PEO 20 ), the molar ratio is 1.5:5:0.2, dissolved in 35ml of deionized water, the concentration of vanadium source is 0.043mol / L, the concentration of sulfur source is 0.143mol / L, and the concentration of P123 is 0.0057mol / L. Magnetic stirring at room temperature for 40 min to obtain a clear solution;

[0029] (3) Put the carbon cloth treated in (1) into the reaction lining, pour the clear solution obtained in (2), seal it for hydrothermal reaction, set the reaction temperature to 180°C and the reaction time to 22h;

[0030] (4) After the reaction, the reaction kettle was naturally cooled to room temperature, and the c...

Embodiment 3

[0033] (1) Cut the carbon cloth into a rectangle of 1 × 5 cm, activate it by refluxing in concentrated nitric acid at 80°C for 2 hours, then wash it with ethanol and deionized water for 5 times, and dry it at 60°C for 7 hours to obtain the treated carbon cloth;

[0034] (2) Weigh Na respectively 3 VO 4 ·12H 2 O, TAA (CH 3 CSNH 2 ) and P123 (PEO 20 PPO 70 PEO 20 ), the molar ratio is 2:4.5:0.2, dissolved in 35ml deionized water, the concentration of vanadium source is 0.057mol / L, the concentration of sulfur source is 0.128mol / L, and the concentration of P123 is 0.0057mol / L. Magnetic stirring at room temperature for 60 min to obtain a clear solution;

[0035] (3) Put the carbon cloth treated in (1) into the reaction lining, pour the clear solution obtained in (2), seal it for hydrothermal reaction, set the reaction temperature to 180°C and the reaction time to 24h;

[0036] (4) After the reaction, the reaction kettle was naturally cooled to room temperature, the carbon c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com