A chrome-free passivator for hot-dip galvanizing

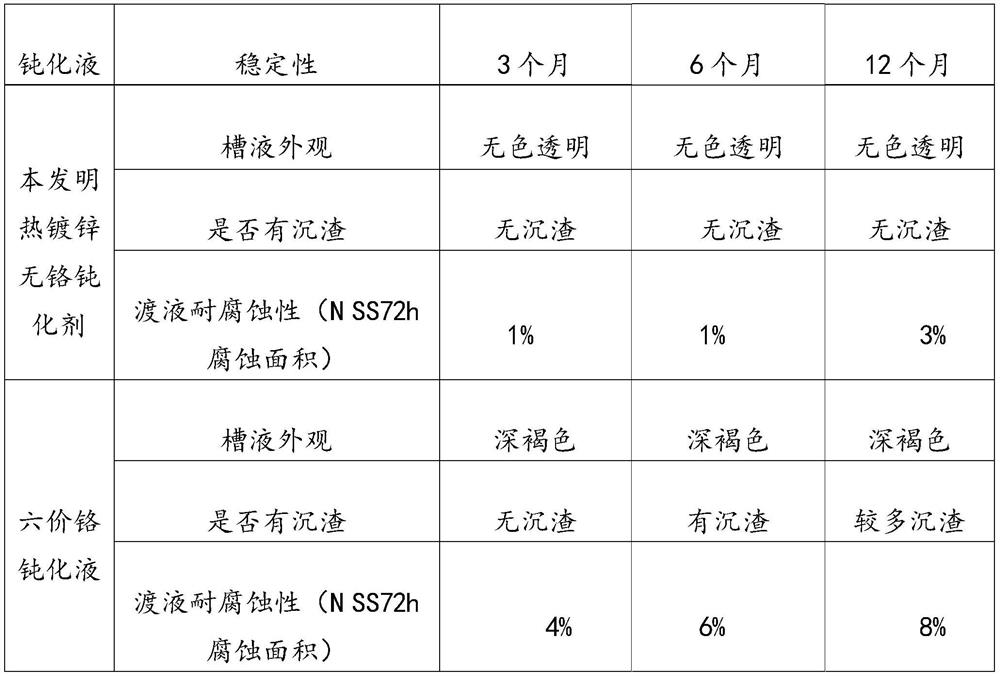

A chrome-free passivator and hot-dip galvanizing technology, which is applied in the coating process of metal materials, can solve the problems of environmental and human impact, toxicity and harm, and achieve the effects of fast drying speed, good stability and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A chromium-free passivator for hot-dip galvanizing, comprising the following raw materials in parts by weight: 7kg of acetic acid, 6kg of oxalic acid, 9kg of phytic acid, 6kg of phosphoric acid, 7kg of nitric acid and 6kg of silica sol;

[0023] The using method of described hot-dip galvanizing chromium-free passivating agent is:

[0024] (1) mixing and stirring each raw material contained in the chromium-free passivating agent for hot-dip galvanizing to obtain the chromium-free passivating agent for hot-dip galvanizing;

[0025] (2) Add water to the chromium-free passivating agent for hot-dip galvanizing, and mix and stir evenly to obtain a passivating solution;

[0026] (3) Immerse the galvanized workpiece to be passivated in the passivation solution for passivation. After the passivation is completed, take out the galvanized workpiece and let it dry.

Embodiment 2

[0028] A chromium-free passivator for hot-dip galvanizing, comprising the following raw materials in parts by weight: 5 kg of acetic acid, 3 kg of oxalic acid, 8 kg of phytic acid, 3 kg of phosphoric acid, 3 kg of nitric acid and 3 kg of silica sol;

[0029] The using method of described hot-dip galvanizing chromium-free passivating agent is:

[0030] (1) Stir each raw material contained in the hot-dip galvanizing chromium-free passivating agent under the stirring condition of 50r / min for 10min, mix and stir evenly, and obtain the hot-dip galvanizing chromium-free passivating agent;

[0031] (2) Add demineralized water to the hot-dip galvanized chromium-free passivator, and the weight ratio of the added demineralized water to the passivator is 18:1 (adding demineralized water can prevent calcium and magnesium ions in the water from interacting with the passivator The raw materials in the reaction will affect the passivation effect of the passivating agent), and mix and stir ev...

Embodiment 3

[0034] A chromium-free passivator for hot-dip galvanizing, comprising the following raw materials in parts by weight: 8 kg of acetic acid, 5 kg of oxalic acid, 10 kg of phytic acid, 5 kg of phosphoric acid, 5 kg of nitric acid and 5 kg of silica sol;

[0035] The using method of described hot-dip galvanizing chromium-free passivating agent is:

[0036] (1) Stir each raw material contained in the chromium-free passivator for hot-dip galvanizing under the stirring condition of stirring speed 55r / min for 15min, mix and stir evenly, and obtain the chromium-free passivator for hot-dip galvanizing;

[0037] (2) Add demineralized water to the hot-dip galvanized chromium-free passivator, and the weight ratio of the added demineralized water to the passivator is 20:1 (adding demineralized water can prevent calcium and magnesium ions in the water from interacting with the passivator The raw materials in the reaction will affect the passivation effect of the passivating agent), and mix a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com