Oil gel with smell masking function and preparation method thereof

An oil-gel and functional technology, which is applied in the field of food processing, can solve the problems of limited expansion and application, and achieve the effects of reducing the degree of oxidation, facilitating transportation, and reducing the risk of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

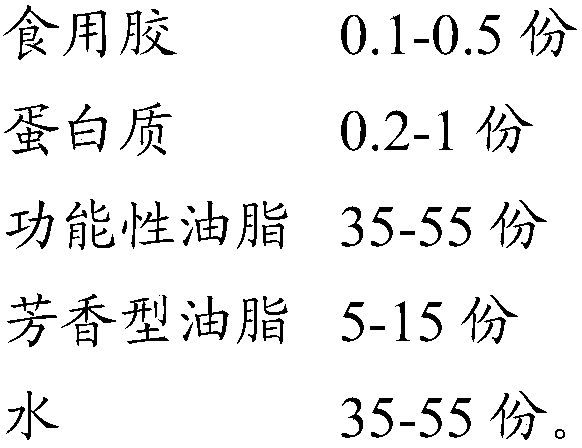

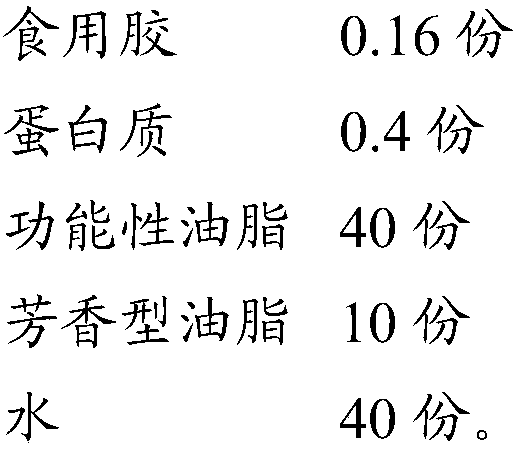

[0027] formula:

[0028]

[0029] Preparation:

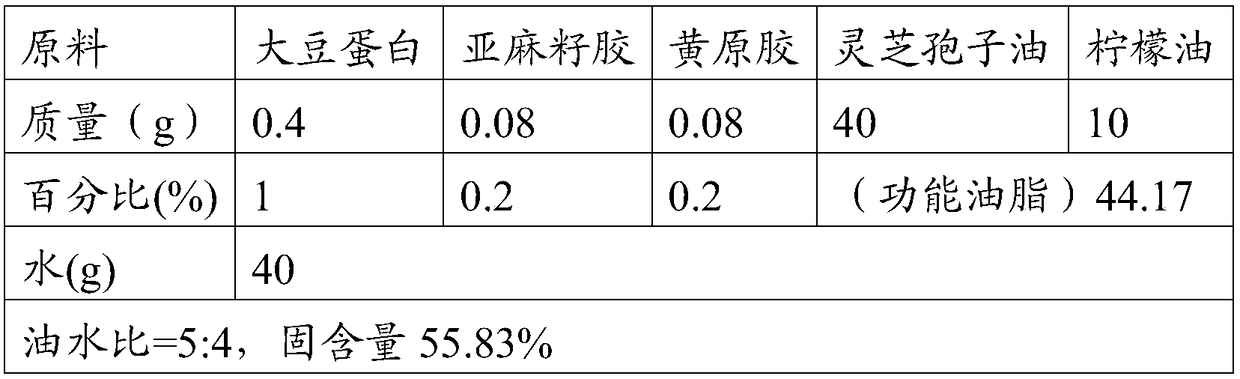

[0030] (1) claim that 40g deionized water is placed in a 100ml beaker, continue to weigh its percentage according to the percentage of water and be respectively 1% soybean protein isolate, 0.2% linseed gum, 0.2% xanthan gum, take by weighing 40g ganoderma lucidum spore oil and 10g lemon oil set aside.

[0031] (2) Soybean protein isolate, linseed gum, and xanthan gum were dispersed in water under a water bath at 70°C. After the dispersion was uniform, ganoderma lucidum spore oil and lemon oil were added therein, and dispersed evenly by magnetic stirring.

[0032] (3) After being uniformly dispersed, use a high-shear machine to cut for 3-5 minutes.

[0033] (4) After shearing, place the above-mentioned soft solid in a centrifuge for 5 minutes at 8000 r / min.

Embodiment 2

[0035]

[0036] (1) 40g deionized water is said to be placed in a 100ml beaker, and its percentages are respectively 1% soybean protein isolate, 0.2% linseed gum, and 0.2% xanthan gum according to the percentage of water, and 40g EPA algae oil and 10g of rose essential oil is set aside for later use.

[0037] (2) Soybean protein isolate, linseed gum, and xanthan gum were dispersed in water in a water bath at 70°C. After the dispersion was uniform, EPA algae oil and rose essential oil were added to it, and dispersed evenly by magnetic stirring.

[0038] (3) After being uniformly dispersed, use a high-shear machine to cut for 3-5 minutes.

[0039] (4) After shearing, place the above-mentioned soft solid in a centrifuge for 5 minutes at 8000 r / min.

Embodiment 3

[0041]

[0042] (1) claim that 40g deionized water is placed in a 100ml beaker, continue to weigh its percentage according to the percentage of water and be respectively 1% soybean protein isolate, 0.2% linseed gum, 0.2% xanthan gum, and take by weighing 40g EPA algae oil, 5g rose essential oil and 5g peppermint oil are set aside for later use.

[0043] (2) Soybean protein isolate, linseed gum, and xanthan gum were dispersed in water in a water bath at 70°C. After the dispersion was uniform, EPA algae oil, rose essential oil, and peppermint oil were added to it, and dispersed evenly by magnetic stirring.

[0044] (3) After being uniformly dispersed, use a high-shear machine to cut for 3-5 minutes.

[0045] (4) After shearing, place the above-mentioned soft solid in a centrifuge for 5 minutes at 8000 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com