Compound protein foaming agent

A technology of compounding protein and foaming agent, applied in protein food processing, vegetable protein processing, protein food ingredients, etc. The effect of reducing the contact area and slowing down the drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

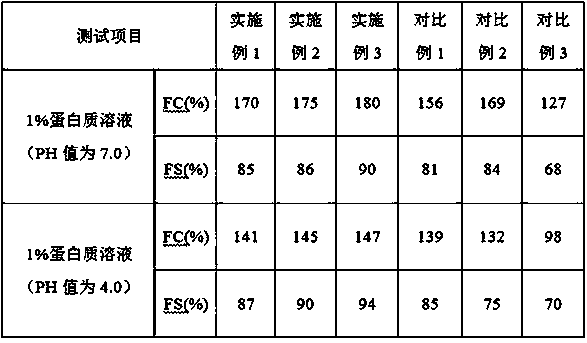

Image

Examples

preparation example Construction

[0029] The preparation method of modified glutinous rice bran protein, comprises the steps:

[0030] (1) According to the mass ratio of 5:1~3, the rice bran and pretreated brewer's grains are crushed through an 80-mesh sieve, and the sieved particles are mixed with adjuvants and reagents according to the mass ratio of 1:0.1:10~15, and mixed at 400~600r / After 30-50 minutes of magnetic stirring, centrifuge at 3500-5500r / min for 15-25 minutes, take the centrifuge and dry it naturally to obtain a degreased product, put the degreased product in a water bath at 45-60°C, and add 3-7 times the degreased product to the degreased product. Mix with ionic water, adjust the pH to 9.2~9.6 with NaOH solution with a concentration of 0.1mol / L, centrifuge at 4000~5500r / min for 15~25min, take the supernatant and adjust the pH to 4.2~4.6 with HCl solution with a concentration of 0.1mol / L , centrifuge at 4000~5000r / min for 12~25min, take the centrifuge, wash it with deionized water 6~10 times the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com