Method for reducing vomitoxin in wheat grain by wet ozone

A technology of vomitoxin and wheat grains, which is applied in the direction of drying seeds, food drying, food science, etc., can solve the problems of high drying energy consumption and high moisture content of wheat, achieve low moisture content, facilitate subsequent drying, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for reducing wheat grain vomitoxin by wet ozone, the preparation method comprising the following steps:

[0033] (1) Determining the content of vomitoxin in wheat grains is 1340μg / kg, weighing 50kg of wheat grains with excessive vomitoxin on an electronic scale, adding 50kg of water, soaking time is 1min, stirring and soaking and draining, the moisture content is determined to be 14.2 %;

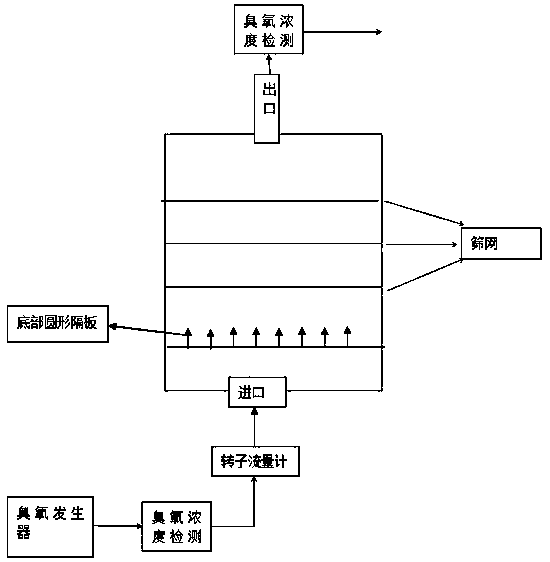

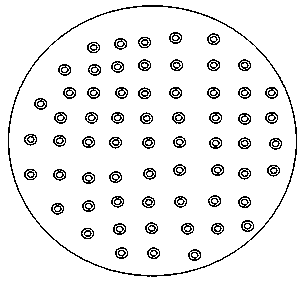

[0034] (2) if figure 1 As shown, the drained wheat grains are placed in an ozone fumigator. The design diameter of the circle at the bottom of the fumigator is 2 meters, and the area of the circle is 31,400 square centimeters. There is a small hole with a diameter of 2 cm. The ozone gas enters from the bottom of the fumigator. The wheat grains are placed on the upper part of the fumigator on the three-layer screen. The thickness of the wheat grains is 1-1.5 cm. Turn on the ozone generator and adjust the ozone concentration at 100mg / L, the flow rate is controlled at 3140 L...

Embodiment 2

[0037] A method for reducing wheat grain vomitoxin by wet ozone, the preparation method comprising the following steps:

[0038] (1) Determining the content of vomitoxin in wheat grains is 1340μg / kg. Weigh 50kg of wheat grains with excessive vomitoxin on an electronic scale, add 75kg of water, stir and soak for 1.5min, drain after soaking, and measure its moisture content 14.4%;

[0039] (2) Place the drained wheat grains in an ozone fumigator. The design diameter of the bottom circle of the fumigator is 2 meters, and the area of the circle is 31,400 square centimeters. The ozone gas enters from the bottom of the fumigator through a small hole of 1 cm, and the wheat grains are placed on the three-layer screen on the upper part of the fumigator. Controlled at 3140 L / min, the control processing time is 40min.

[0040] (3) After detoxification, the wheat is placed in a boiling dryer, the temperature is controlled at 40°C, the air volume is 7000m / h, and it is treated for 15 mi...

Embodiment 3

[0042] A method for reducing wheat grain vomitoxin by wet ozone, the preparation method comprising the following steps:

[0043] (1) Determining the content of vomitoxin in wheat grains is 1340μg / kg. Weigh 500kg of wheat grains with excessive vomitoxin on an electronic scale, add 600kg of water, stir and soak for 1.2min, drain after soaking, and measure its water content The content is 14.4%;

[0044] (2) Place the drained wheat grains in an ozone fumigator. The design diameter of the bottom circle of the fumigator is 2 meters, and the area of the circle is 31,400 square centimeters. The ozone gas enters from the bottom of the fumigator through a small hole of 1 cm, and the wheat grains are placed on the three-layer screen on the upper part of the fumigator. It is controlled at 3140 L / min, and the control processing time is 35 minutes.

[0045] (3) After detoxification, the wheat was placed in a boiling dryer with a controlled temperature of 40°C and an air volume of 6500m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com