Composite catalyst and method for preparing same

A composite catalyst, catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low OH selectivity, improve dispersibility, improve yield, and increase selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

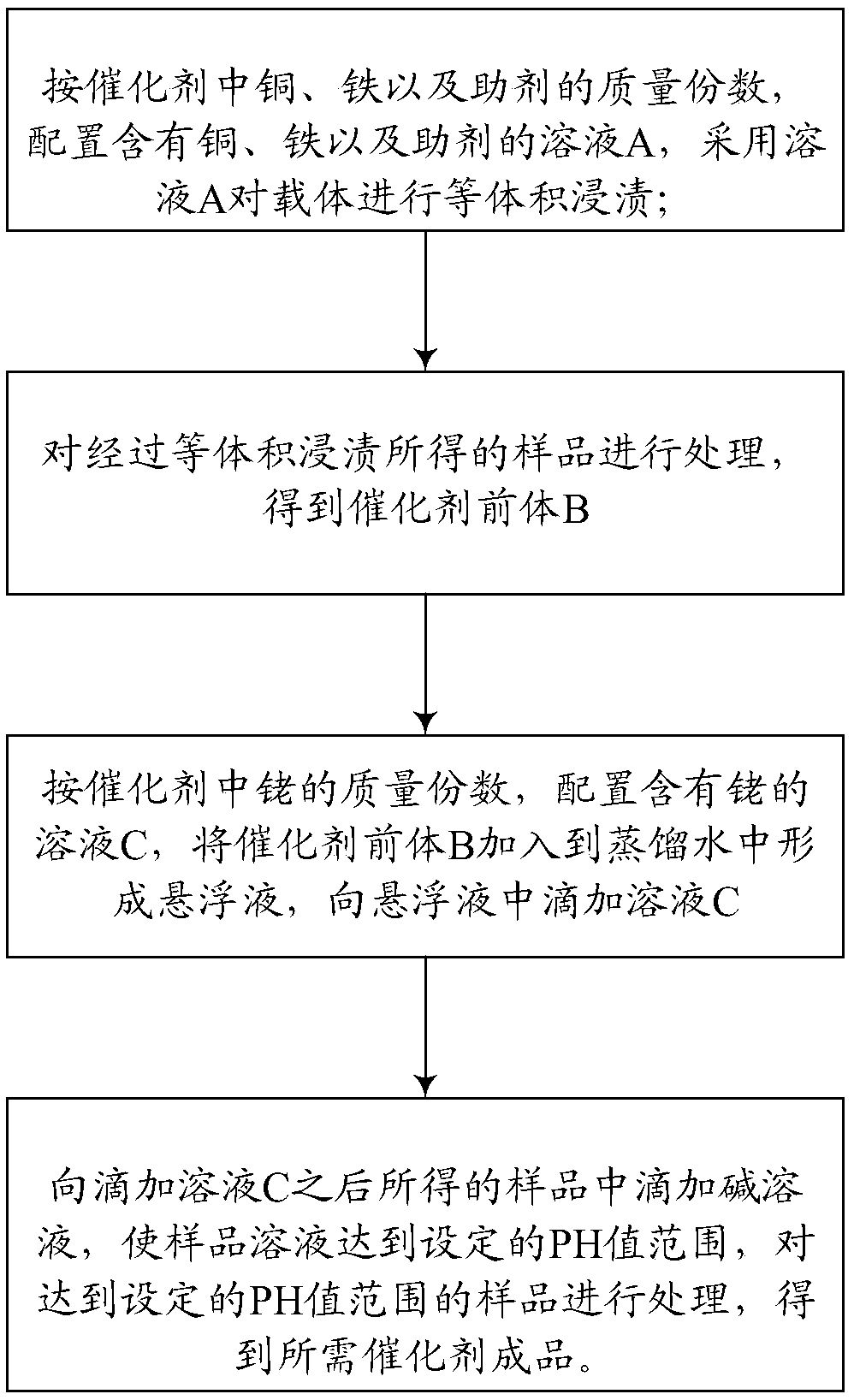

[0037] see figure 1 , the embodiment of the present invention also provides a kind of preparation method of composite catalyst, is used for preparing composite catalyst as described above, and this preparation method comprises: according to the mass fraction of copper, iron and auxiliary agent in composite catalyst, configuration contains copper , iron and auxiliary agent solution A, adopt solution A to carry out equal volume impregnation to carrier; Process the sample obtained through equal volume impregnation, obtain catalyst precursor B; Press the mass fraction of rhodium in the composite catalyst, configure rhodium-containing Solution C, add catalyst precursor B to distilled water to form a suspension, add solution C dropwise to the suspension; add alkali solution dropwise to the sample obtained after adding solution C, so that the sample solution reaches the set pH range , to process the samples reaching the set pH range to obtain the desired composite catalyst finished p...

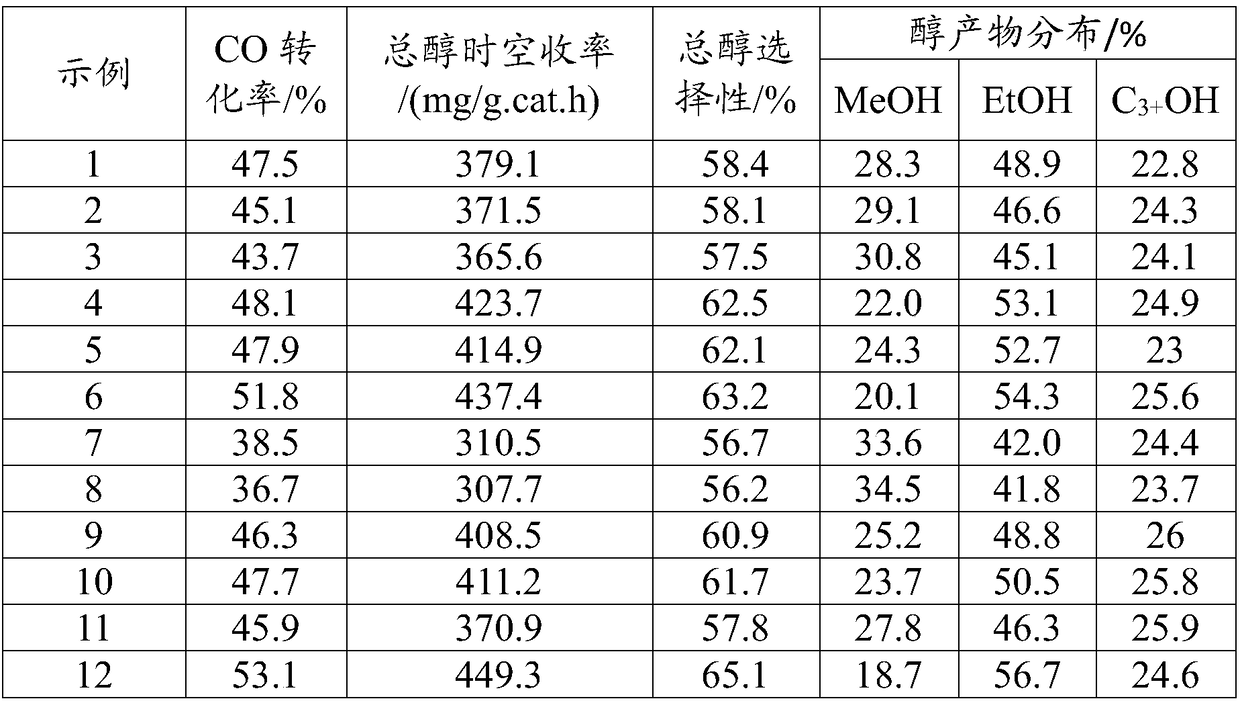

example 1

[0048] The preparation process of the composite catalyst is as follows:

[0049] Composite catalyst components Cu:Fe:Rh:Zn:γ-Al 2 o 3 The mass percentage is 8:5:1:5:81, 15.1g of copper nitrate trihydrate, 18g of iron nitrate nonahydrate, 4g of rhodium nitrate (35% solution), 11.4g of zinc nitrate hexahydrate, 40.5g of aluminum oxide g. Dissolve copper nitrate trihydrate, ferric nitrate nonahydrate, and zinc nitrate hexahydrate into 50 mL of deionized water to form a uniform solution A; add solution A dropwise to a medium volume of alumina for impregnation, and leave the sample for 12 hours after adding solution A; The obtained sample was vacuum-dried at 60° C. for 6 hours; calcined at 400° C. under nitrogen for 6 hours to obtain catalyst precursor B.

[0050] Catalyst precursor B was added to 200 mL of deionized water and stirred for 1 hour to form a suspension. Take 0.3 mL of concentrated nitric acid with a concentration of 68% and dilute it to 50 mL, add weighed rhodium ...

example 2

[0054] The preparation process of the composite catalyst is as follows:

[0055] Composite catalyst components Cu:Fe:Rh:Mn:γ-Al 2 o 3 The mass percentage is 10:6:0.5:2:81.5, weighs copper nitrate trihydrate 18.9g, ferric nitrate nonahydrate 21.6g, rhodium nitrate (35% solution) 2g, manganese nitrate (concentration 50% solution) 6.5g, 40.8g of alumina. Copper nitrate trihydrate, ferric nitrate nonahydrate, and manganese nitrate were dissolved in 50 mL of deionized water to form a uniform solution A; solution A was added dropwise to a medium volume of alumina for impregnation, and solution A was ultrasonically treated for 2 hours after the solution was added; the resulting sample was 90 vacuum drying at ℃ for 4 hours; calcination at 300 ℃ for 8 hours under nitrogen to obtain catalyst precursor B.

[0056] Catalyst precursor B was added to 200 mL of deionized water and stirred for 1 hour to form a suspension. Take 0.15mL of concentrated nitric acid with a concentration of 68%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com