Integrated treatment method of high-concentration liquid crystal waste water

A treatment method and high-concentration technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve environmental pollution and other problems, achieve good treatment effect, safe and stable operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

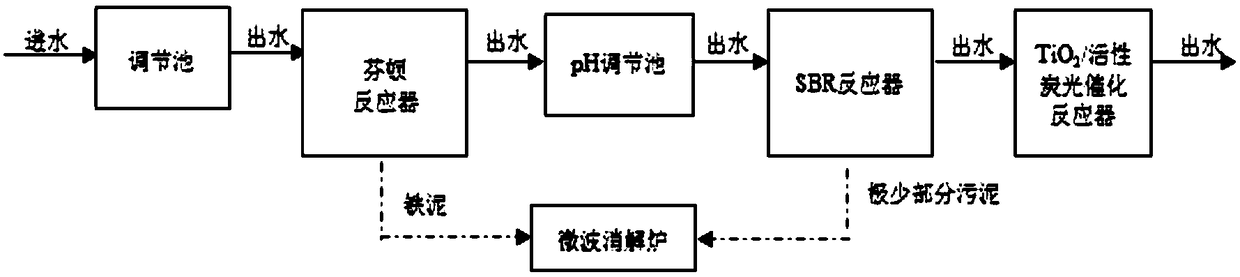

[0033] Example 1: Fenton-SBR-TiO 2 / Activated carbon-microwave digestion sludge new combination process for high concentration liquid crystal wastewater

[0034] In this embodiment, the liquid crystal wastewater produced by a chemical plant is selected. Its COD concentration is as high as 300,000mg / L, and its pH value is 5-6. In order to improve the safety and efficiency of the Fenton reaction, the liquid crystal wastewater enters the Fenton reactor. Adjust the water quality so that the COD concentration of the wastewater entering the Fenton reactor is 150,000 mg / L, and the pH is about 3; the wastewater is oxidized in the Fenton reactor for about 30-60 minutes, then the reaction is stopped and the supernatant and iron sludge are separated, and the iron sludge is digested by microwave After resource recovery, the supernatant effluent enters the SBR reactor after pH adjustment, and reacts in the SBR reactor for about 20 hours to stop the reaction. After a period of rest, the sup...

Embodiment 2

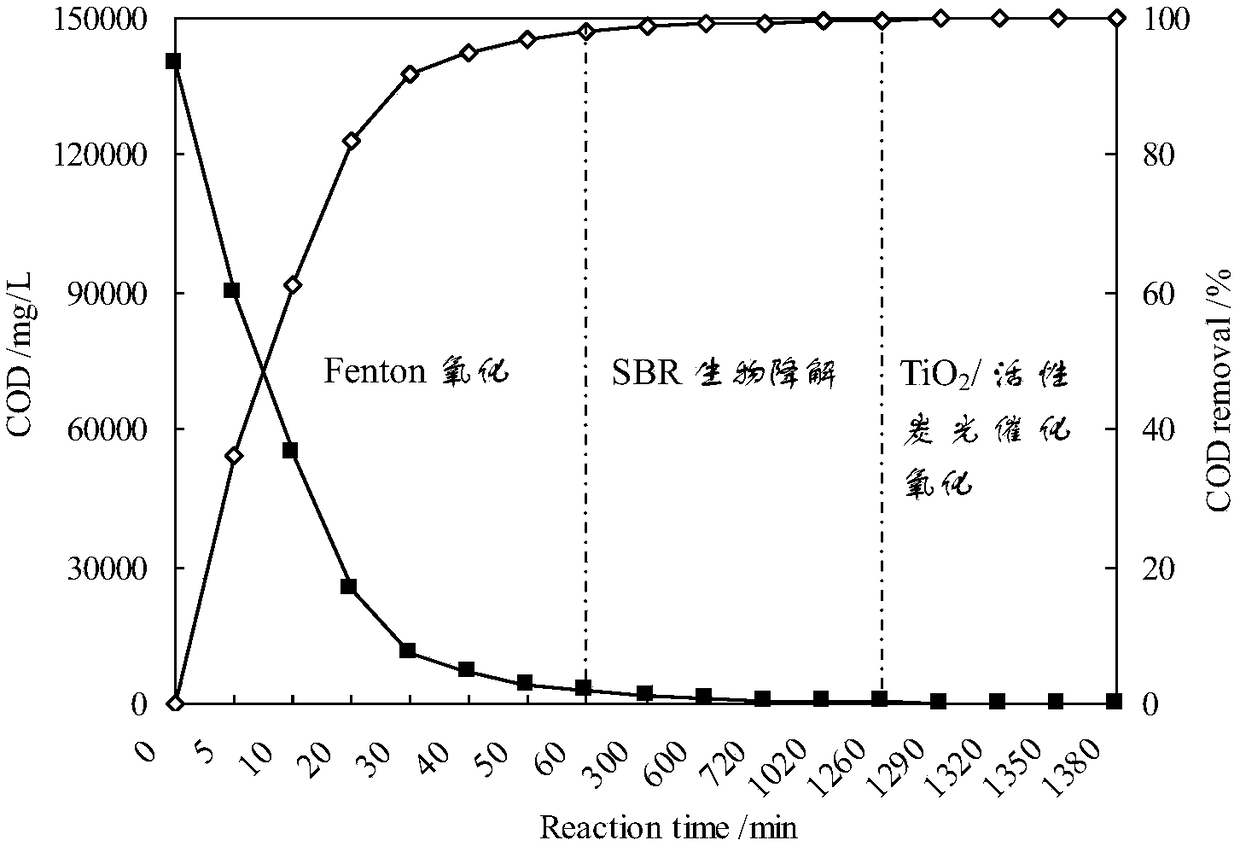

[0035] Embodiment 2: the removal situation of COD in high-concentration liquid crystal wastewater

[0036] In this embodiment, the high-concentration liquid crystal wastewater in embodiment 1 passes through Fenton-SBR-TiO 2 After the combined process of activated carbon photocatalysis, the removal of COD in each section is as follows figure 2 As shown in the figure, it can be seen from the figure that after 60 minutes of Fenton oxidation pretreatment of liquid crystal wastewater, the COD concentration is reduced from 150,000 mg / L to 2800 mg / L, and the COD removal rate at this stage is as high as 98%. Then the Fenton effluent enters the SBR unit for 20 hours , the COD concentration dropped from 2800mg / L to 512mg / L, and the COD removal rate at this stage was about 82%; finally, the SBR effluent entered TiO 2 / The activated carbon photocatalytic reactor reacted for 2 hours, the COD concentration dropped from 512mg / L to 42mg / L, and the COD water quality index was lower than the...

Embodiment 3

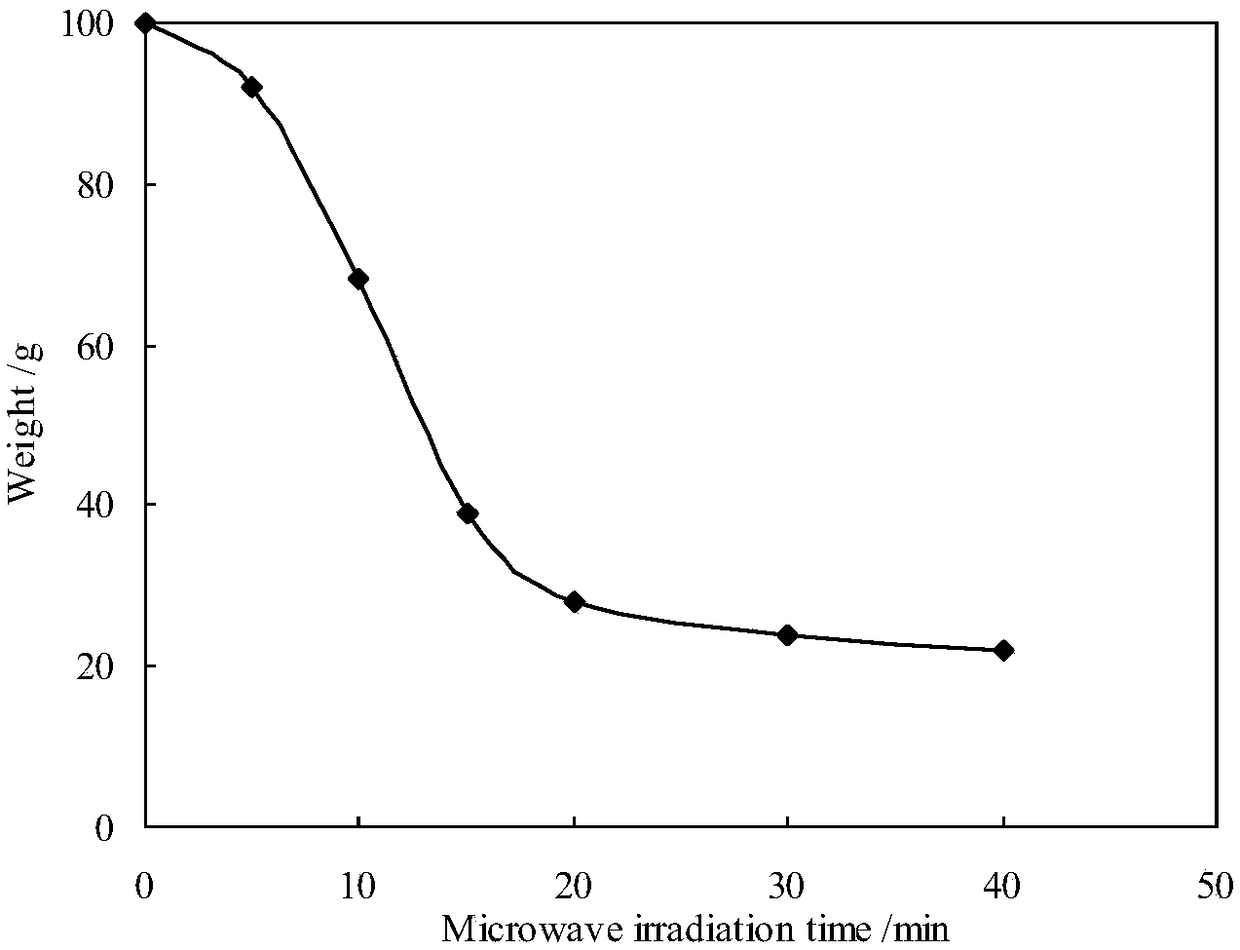

[0037] Embodiment 3: the weight change situation of the generated sludge (mainly iron sludge) after microwave drying

[0038] In this embodiment, the sludge produced in the two sections of Fenton pretreatment and SBR in Example 1 is concentrated and then dried in a microwave oven. The weight of the sludge varies with the microwave digestion time as follows: image 3 As shown, it can be seen from the figure that in the first 20 minutes, the sludge weight decreased sharply with the increase of microwave digestion time; between 20 and 30 minutes, the sludge weight tended to be stable with the extension of microwave digestion time, and 30 minutes The weight of the sludge remained basically the same, which means that the sludge was completely dried, and the sludge was changed from 100g to 24g; during the microwave drying process, the water and a part of the sludge evaporated in the form of water vapor and ash. The remaining composition is mainly Fe(OH) 3 , At the same time, the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com