Degradable environment-friendly plastic bag

A plastic bag, an environmentally friendly technology, applied in the field of plastics, can solve the problems of poor tensile strength and elongation at break, unusable damage, living environment pollution, etc., to achieve high tensile strength, avoid pollution, and good flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

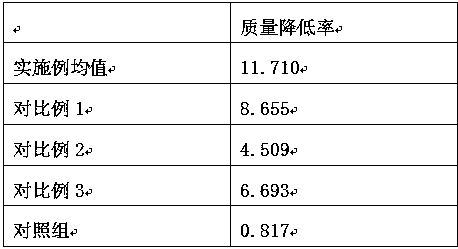

Examples

Embodiment 1

[0019] A degradable environment-friendly plastic bag, containing 15% of its quality cetearyl glucoside modified biodegradation agent in the degradable environment-friendly plastic bag.

[0020] Further, the preparation method of the cetearyl glucoside modified biodegradation agent is:

[0021] (1) Add the polyvinyl alcohol-polyethylene glycol graft copolymer and aliphatic polyester-polyethylene glycol block copolymer into dichloromethane at a ratio of 35g: 42g: 380ml, and heat to 70 °C, stirred at 320r / min for 2 hours to obtain a mixed solution;

[0022] (2) Add its quality 0.12% coconut oil monoethanolamide, 1.38% propylene glycol fatty acid ester and 10% deionized water to the mixed solution configured in step (1), then stir for 2 hours with 1500r / min rotating speed , and then ultrasonically treated for 2.5 minutes to obtain an emulsion;

[0023] (3) Heat the emulsion obtained above to 86°C, add 0.35% stearylamide and 1.5% secondary alcohol to the emulsion, stir at 1500r / m...

Embodiment 2

[0032] A kind of degradable environment-friendly plastic bag, containing its mass 16% cetearyl glucoside modified biodegradation agent in the described degradable environment-friendly plastic bag.

[0033] Further, the preparation method of the cetearyl glucoside modified biodegradation agent is:

[0034] (1) Add the polyvinyl alcohol-polyethylene glycol graft copolymer and the aliphatic polyester-polyethylene glycol block copolymer into dichloromethane at a ratio of 38g: 44g: 390ml, and heat to 70 °C, stirred at 320r / min for 2 hours to obtain a mixed solution;

[0035] (2) Add its quality 0.12% coconut oil monoethanolamide, 1.38% propylene glycol fatty acid ester and 10% deionized water to the mixed solution configured in step (1), then stir for 2 hours with 1500r / min rotating speed , and then ultrasonically treated for 2.5 minutes to obtain an emulsion;

[0036] (3) Heat the emulsion obtained above to 86°C, add 0.35% stearylamide and 1.5% secondary alcohol to the emulsion,...

Embodiment 3

[0045] A kind of degradable environment-friendly plastic bag, contains the cetearyl glucoside modification biodegradation agent of its quality 15.6% in the described degradable environment-friendly plastic bag.

[0046] Further, the preparation method of the cetearyl glucoside modified biodegradation agent is:

[0047] (1) Add the polyvinyl alcohol-polyethylene glycol graft copolymer and aliphatic polyester-polyethylene glycol block copolymer into dichloromethane at a ratio of 36g: 43g: 385ml, and heat to 70 °C, stirred at 320r / min for 2 hours to obtain a mixed solution;

[0048] (2) Add its quality 0.12% coconut oil monoethanolamide, 1.38% propylene glycol fatty acid ester and 10% deionized water to the mixed solution configured in step (1), then stir for 2 hours with 1500r / min rotating speed , and then ultrasonically treated for 2.5 minutes to obtain an emulsion;

[0049] (3) Heat the emulsion obtained above to 86°C, add 0.35% stearylamide and 1.5% secondary alcohol to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com