Method for producing single cell protein through double-bacteria step fermentation taking ethyl alcohol as transition carbon source

A single-cell protein, step-by-step fermentation technology, applied in the field of double-bacteria step-by-step fermentation to produce single-cell protein, can solve the problems of long fermentation cycle and low carbon source utilization efficiency, and achieves improved utilization efficiency, slow down catabolism inhibition, production The effect of speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

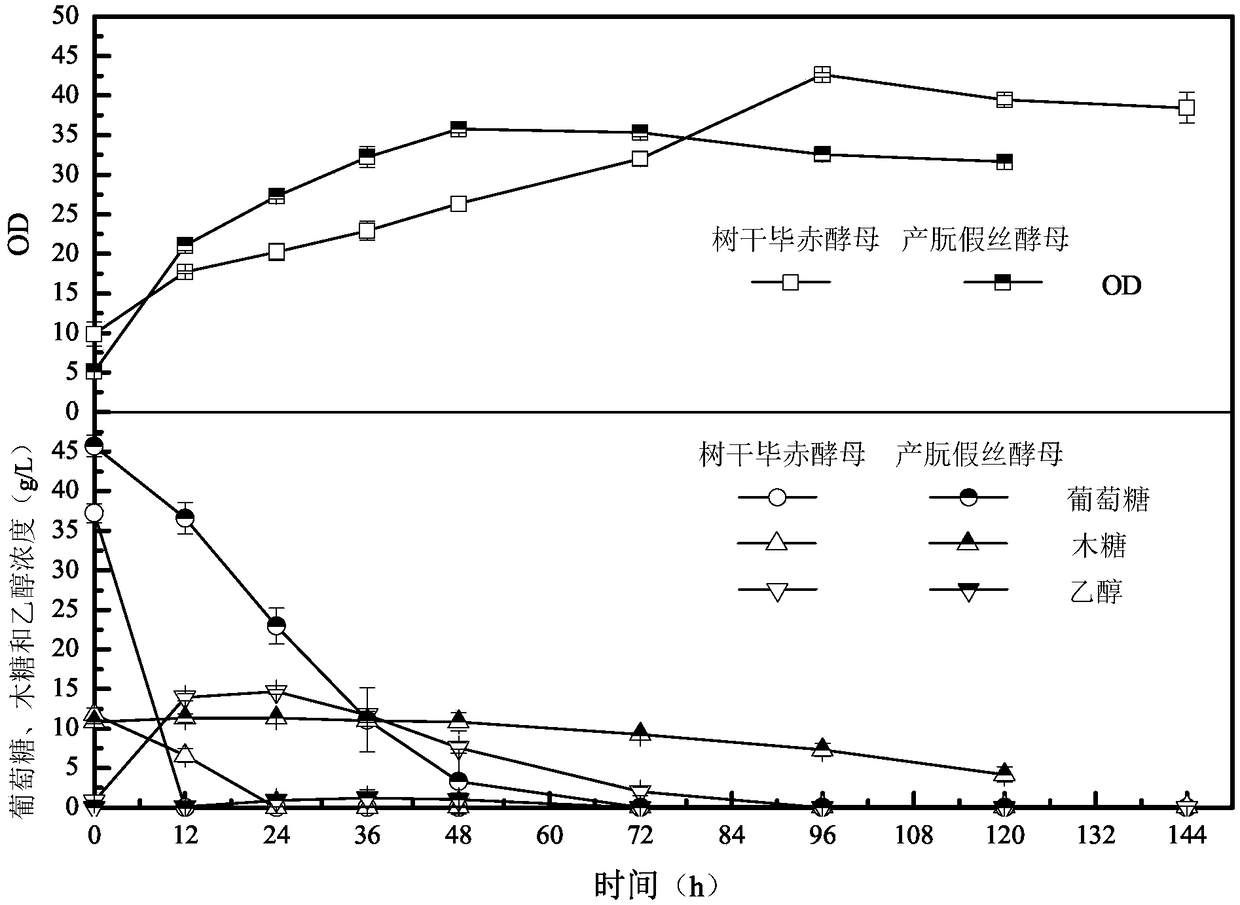

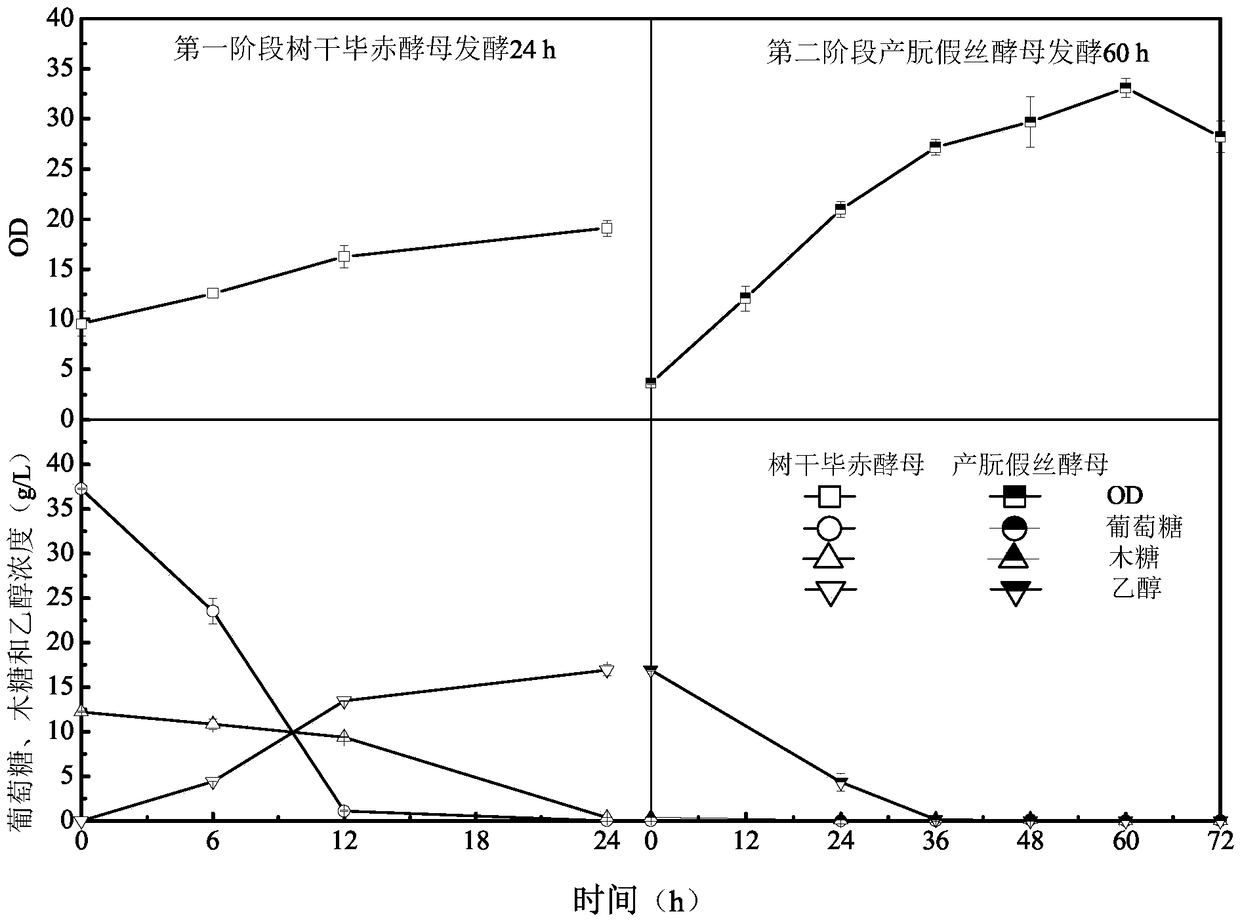

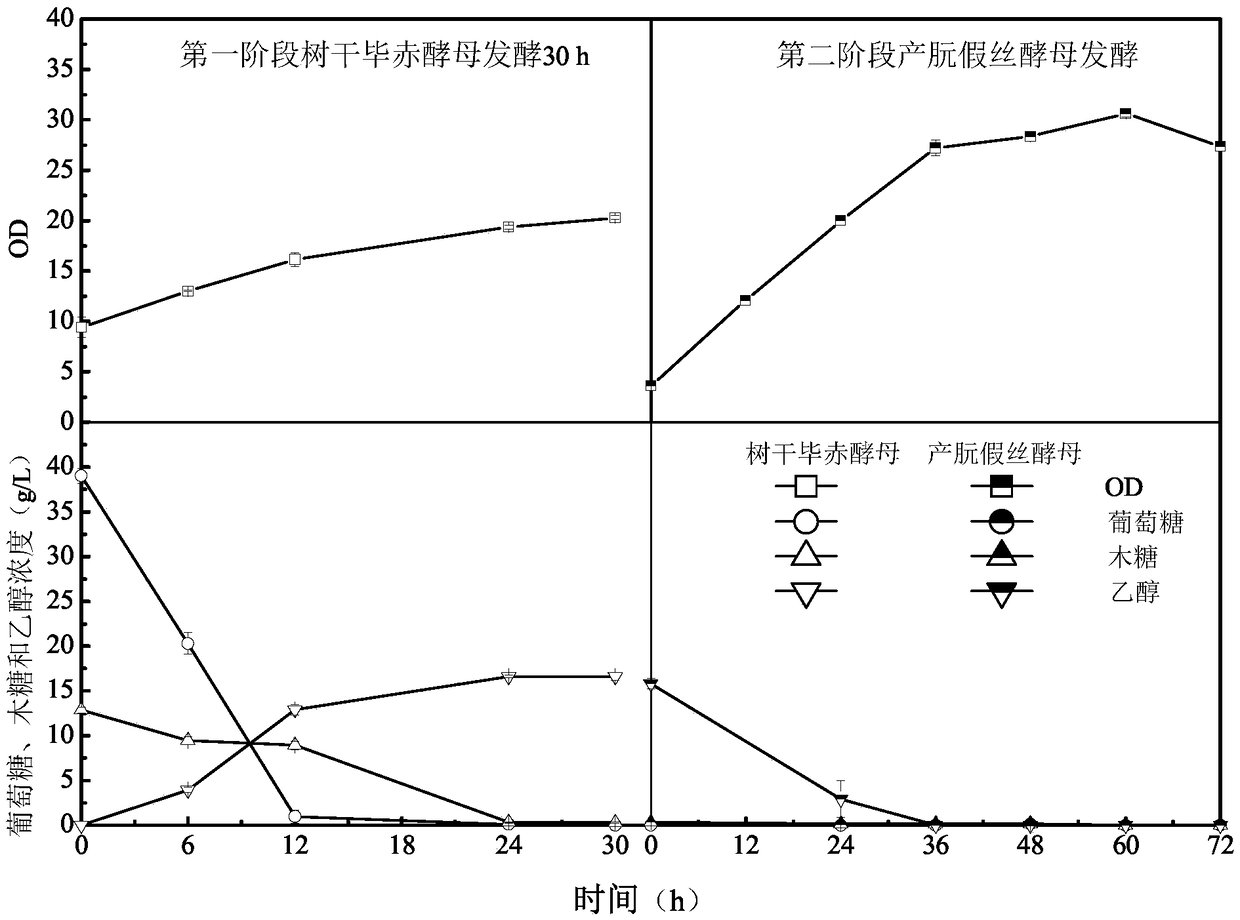

[0034] Double-bacteria step-by-step fermentation to produce single-cell protein, the steps are as follows:

[0035] (1) Using mixed sugar as a carbon source, add nitrogen source and inorganic salts in Pichia stipitis fermentation medium, after sterilization, insert Pichia stipitis CBS 5776 into a constant temperature shaker culture, 30°C, 150r / min, ferment for 24-36 hours; the ventilation method is in the form of non-baffled Erlenmeyer flask and cotton plug. The fermentation broth was centrifuged to obtain the bacteria and ethanol-containing supernatant. The precipitate (thalline) obtained by centrifugation is washed and dried as single-cell protein; the resulting ethanol-containing supernatant is used for the production of single-cell protein by Candida utilis. Among them, Pichia stipitis needs to be activated for 36 hours and after a round of proliferation (24 hours), it is inserted into the fermentation, and the initial OD of the fermentation broth inserted into Pichia st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com