Production method for enzymatic reaction by utilizing adenosine to replace ATP

A technology of enzymatic reaction and production method, which is applied in the biological field to achieve the effects of low price, wide source and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 crude enzyme

[0051] The ATP regenerating enzyme and AK enzyme in the method of the present invention can be obtained commercially, or are artificially modified enzymes having the same catalytic function.

[0052] The enzyme preparation process is as follows:

[0053] Primers were designed according to the gene sequences of PPK enzyme, ADK enzyme, PAP enzyme and AK enzyme, and the gene fragments were respectively amplified by PCR and connected to the pET22b vector (commercially available). After the sequencing was correct, they were respectively transferred into E .coli BL21(DE3) strain (commercially available).

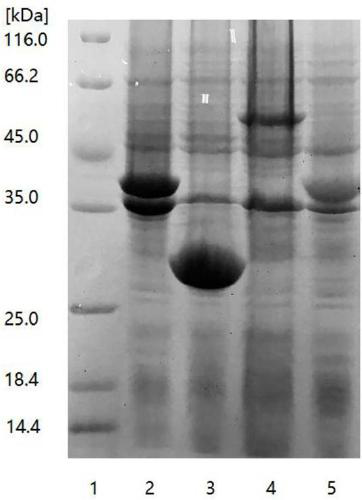

[0054] Insert the transformed E.coli BL21(DE3) monoclonal into LB medium, culture to the logarithmic phase, add 1mM isopropyl-β-D-thiogalactopyranoside (IPTG) for induction, induce The cells were collected after 5 hours, and high-expression strains were screened by sodium dodecylsulfonate-polyacrylamide gel electrophoresis (S...

Embodiment 2

[0059] Embodiment 2 enzymatic method produces creatine phosphate

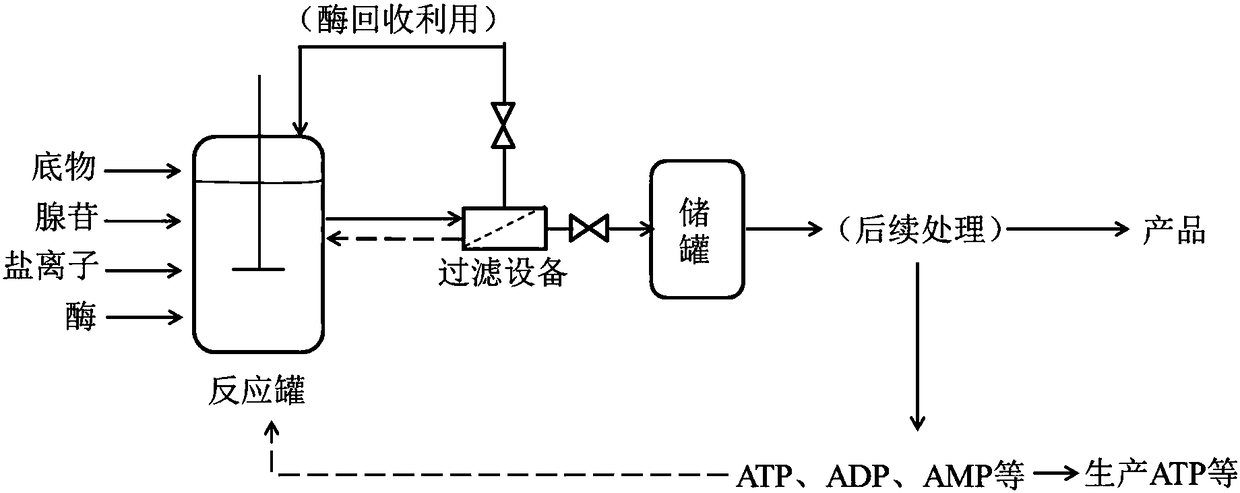

[0060] figure 2 A flow diagram of the reaction process using free enzymes for the present invention. Such as figure 2 Shown, the operation steps of enzymatic preparation creatine phosphate are as follows:

[0061] (1) The reaction of synthesizing creatine phosphate in the reaction tank:

[0062] In the reaction tank, the 100L reaction system is a substrate containing 2.0kg creatine, 0.2kg adenosine, 1.8kg sodium polyphosphate, 0.4kg potassium chloride, 0.5kg magnesium chloride hexahydrate and 0.3kg disodium hydrogen phosphate When preparing the solution, stir evenly to prevent precipitation. Adjust the pH value to 7.0, add creatine kinase 1000U / L, PPK enzyme 500U / L, ADK enzyme 500U / L and AK enzyme 500U / L to the reaction system to start the reaction. During the reaction, the pH value was controlled to be 7.0, and the temperature was 35°C.

[0063] Figure 4 It is a diagram of the remaining amount of cre...

Embodiment 3

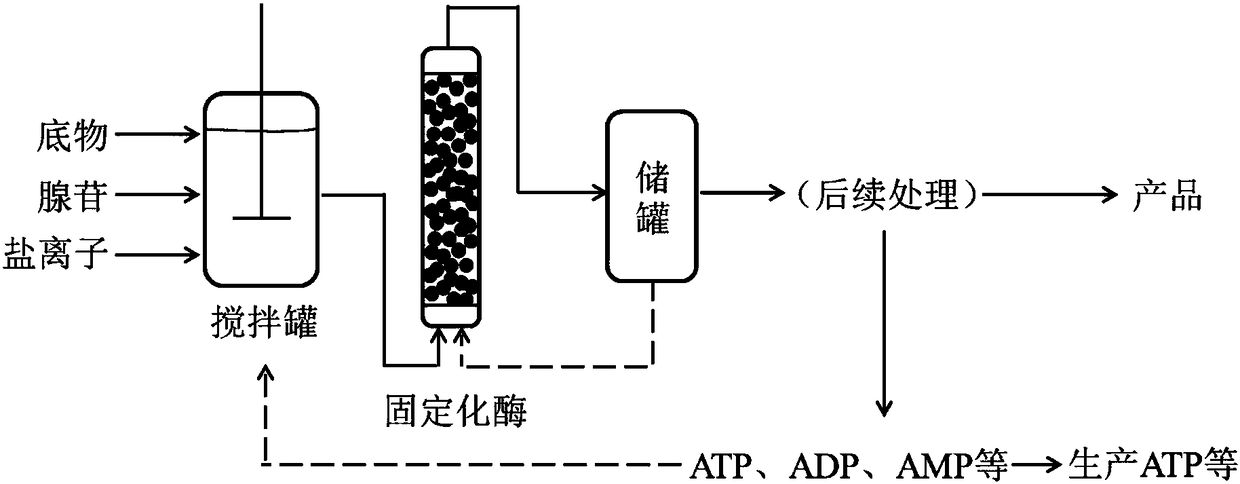

[0067] Embodiment 3 enzymatic method produces 1,6-diphosphate fructose (immobilized enzyme)

[0068] image 3 Process flow diagram for the reaction of the method of the present invention using immobilized enzymes. Such as image 3 As shown, the operation steps for preparing 1,6-diphosphate fructose by the immobilized enzyme method are as follows:

[0069] (1) Immobilization of catalytic enzyme, ATP regeneration enzyme and AK enzyme:

[0070] Catalytic enzymes fructokinase (FK) and phosphofructokinase (PFK) were obtained commercially, and together with ADK enzyme, PAP enzyme and AK enzyme initially purified in Example 1, were immobilized on the commercial epoxy immobilized carrier LX1000EP.

[0071] Mix FK, PFK, ADK, PAP and AK enzymes according to the activity ratio of 2:2:1:1:1 to make a mixed enzyme solution, and the AK enzyme activity in the enzyme solution is 2000U / L. Add 2 kg of LX1000EP wet carrier to the constant temperature stirring tank to mix with the above enzym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com