Air busbar

A busway and air-type technology, applied in the field of air-type busway and its preparation, can solve the problems of large tolerance accuracy error, low hardness, strength, wear resistance and corrosion resistance of die castings, and reduce product cracks. , strong binding, strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

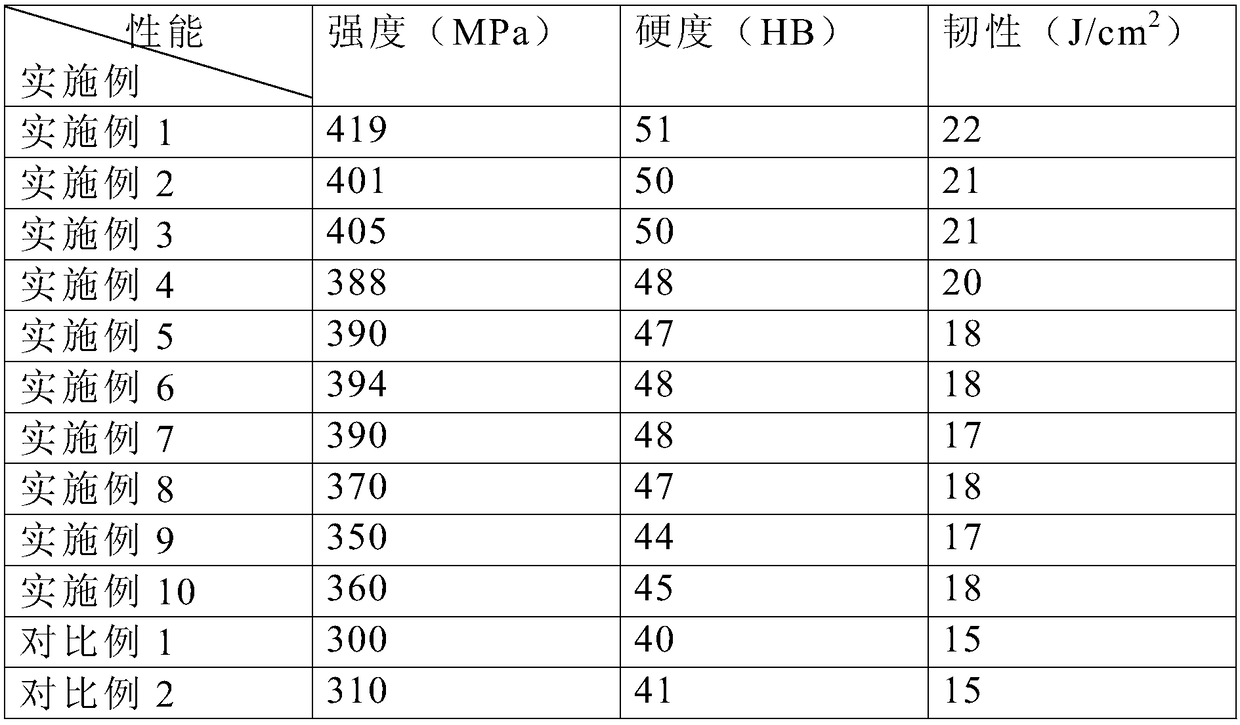

Examples

Embodiment 1

[0040] Ingredients: configure the aluminum-magnesium alloy raw materials according to the above-mentioned ingredients, including the following raw materials in parts by weight:

[0041] Si powder: 6 parts

[0042] Mg powder: 18 parts

[0043] Hydride: 12 parts

[0044] Ni powder: 3 parts

[0045] Sn powder: 5 parts

[0046] Al powder: 2300 parts;

[0047] Among them, hydrides include metal hydrides and metalloid hydrides, and metal hydrides include BaH with a particle size of 450nm 2 Powder, RbH powder, CuH powder ternary mixed powder 4 parts, metalloid hydrides include AsH 3 、H 2 Te, SbH 3 The mixture of Si powder, Mg powder, Ni powder and Sn powder is controlled by mechanical means such as ball milling to be 550nm, and the particle size of Al powder is 650nm.

[0048] Molding: Spread metal hydride powder BaH evenly on the inner surface of the shell mold 2 Powder, RbH powder, CuH powder ternary mixed powder, and then other alloy powders in order of particle size from...

Embodiment 2

[0051] Ingredients: configure the aluminum-magnesium alloy raw materials according to the above-mentioned ingredients, including the following raw materials in parts by weight:

[0052] Si powder: 5 parts

[0053] Mg powder: 16 parts

[0054] Hydride: 8 parts

[0055] Ni powder: 1 part

[0056] Sn powder: 3 parts

[0057] Al powder: 2200 parts;

[0058] The hydrides include metal hydrides and metalloid hydrides, and the metal hydrides include BaH with a particle size of 400nm 2 powder, RbH powder binary mixed powder 2 parts, metalloid hydrides including AsH 3 、H 2 Te mixture, and control the particle size of Si powder, Mg powder, Ni powder, Sn powder to 500nm, and the particle size of Al powder to 600nm by mechanical means such as ball milling.

[0059] Molding: Spread metal hydride powder BaH evenly on the inner surface of the shell mold 2 powder, RbH powder binary mixed powder, and other alloy powders from large to small particle size, fill the mold from the bottom of ...

Embodiment 3

[0062] Ingredients: configure the aluminum-magnesium alloy raw materials according to the above-mentioned ingredients, including the following raw materials in parts by weight:

[0063] Si powder: 7 parts

[0064] Mg powder: 20 parts

[0065] Hydride: 16 parts

[0066] Ni powder: 5 parts

[0067] Sn powder: 7 parts

[0068] Al powder: 2400 parts;

[0069] Among them, hydrides include metal hydrides and metalloid hydrides, metal hydrides include 6 parts of RbH powder and CuH powder binary mixed powder with a particle size of 500nm, and metalloid hydrides include H 2 Te, SbH 3 Mixture, and control the particle size of Si powder, Mg powder, Ni powder, Sn powder to 600nm, and the particle size of Al powder to 700nm by mechanical means such as ball milling.

[0070] Molding: Evenly spread metal hydride powder RbH powder and CuH powder binary mixed powder on the inner surface of the shell mold, and then fill the mold from the bottom of the mold upwards with other alloy powders...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com