Far-infrared and antistatic polyester functional fiber with good moisture absorption

A functional fiber and antistatic technology, applied in the field of polyester fiber, can solve problems such as poor performance, poor hygroscopicity, and low moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

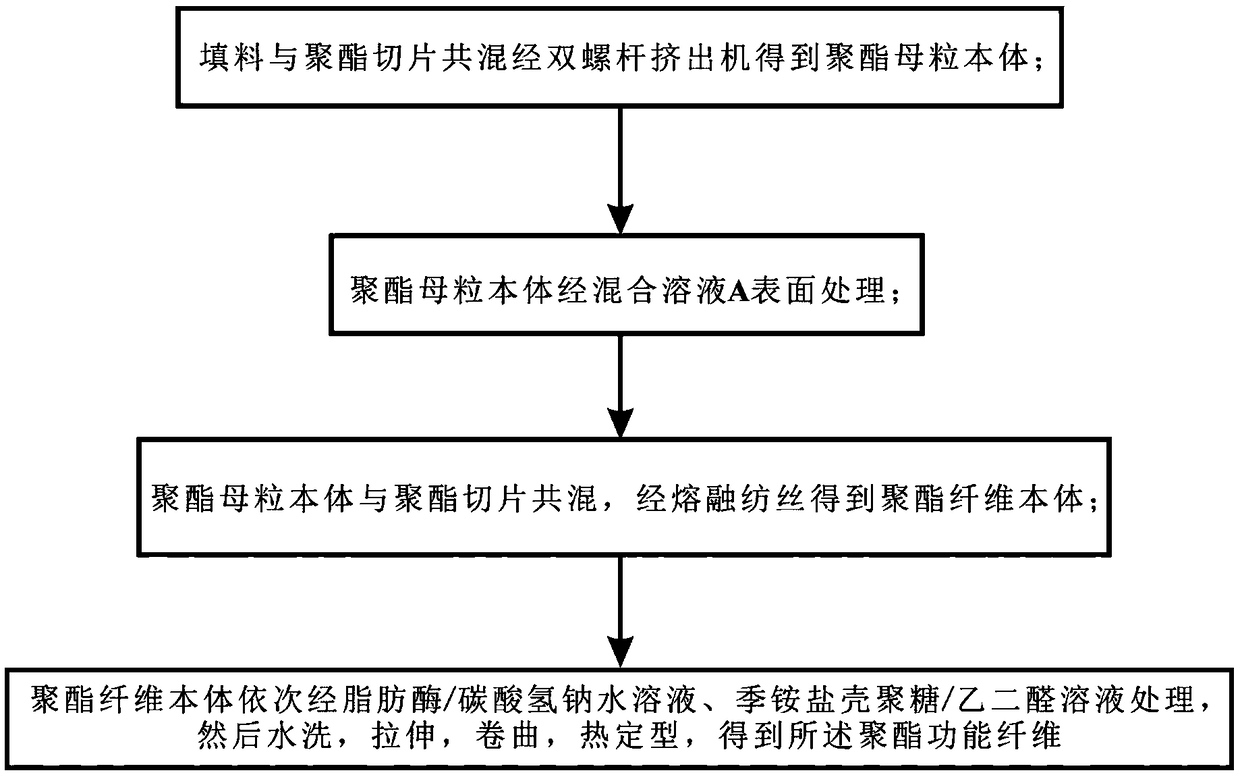

Method used

Image

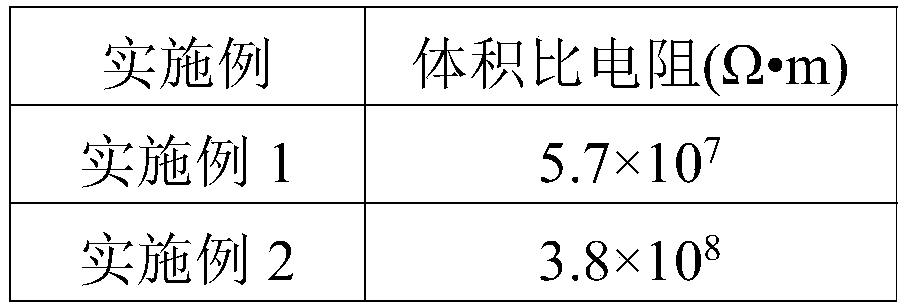

Examples

Embodiment 1

[0063] The following is the preparation process of polyester functional fiber of the present invention:

[0064] Step 1, take 100mL of HAuCl with a concentration of 0.25mmol / L 4 solution, add 1mL sodium citrate aqueous solution with a concentration of 5wt.%, and then heat to boiling, stop heating 5min after the solution turns wine red, centrifuge to obtain Au nanoparticles, after washing, add Au nanoparticles to 1000mL super In pure water, an aqueous solution of Au nanoparticles was obtained and stirred evenly;

[0065] Take 5 mL of Au nanoparticle aqueous solution, add 32.5 μL of 0.2 mol / L ascorbic acid aqueous solution to it, and then add HAuCl 4 Make the concentration 0.25mmol / L, then adjust the pH value to 5.8 by dropwise adding 0.1mol / L NaOH solution, after centrifugal dispersion, wash the precipitate to obtain gold nanoflower particles;

[0066] Step 2: Dry the polyester chips, then mix the polyester chips and fillers in a high-speed mixer according to the mass ratio o...

Embodiment 2

[0072] The following is the preparation process of polyester functional fiber of the present invention:

[0073] Step 1, take 100mL of HAuCl with a concentration of 0.25mmol / L 4 solution, add 1mL sodium citrate aqueous solution with a concentration of 5wt.%, and then heat to boiling, stop heating 5min after the solution turns wine red, centrifuge to obtain Au nanoparticles, after washing, add Au nanoparticles to 1000mL super In pure water, an aqueous solution of Au nanoparticles was obtained and stirred evenly;

[0074] Take 5 mL of Au nanoparticle aqueous solution, add 32.5 μL of 0.2 mol / L ascorbic acid aqueous solution to it, and then add HAuCl 4 Make the concentration 0.25mmol / L, then adjust the pH value to 5.8 by dropwise adding 0.1mol / L NaOH solution, after centrifugal dispersion, wash the precipitate to obtain gold nanoflower particles;

[0075] Step 2: Dry the polyester chips, then mix the polyester chips and fillers in a high-speed mixer according to the mass ratio o...

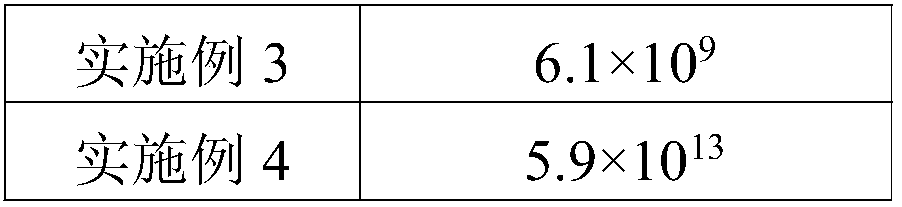

Embodiment 3

[0081] The preparation process of the polyester functional fiber described in this embodiment is as in Example 1, the difference is:

[0082] In this embodiment, the contents of the fillers in the polyester functional fibers are: carbon nanotubes 3wt.%, ZrO 2 Nanoparticles 0.6wt.%, TiO 2 Nanoparticles 0.3wt.%, talcum powder 2wt.%, dispersant 3wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com