High-strength and water-permeable concrete and preparation method thereof

A technology of water permeability and concrete, which is applied in the field of concrete, can solve problems such as the contradiction between strength and water permeability, limit the use of permeable concrete, and poor work performance, and achieve the effects of improving drainage, prolonging durability, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

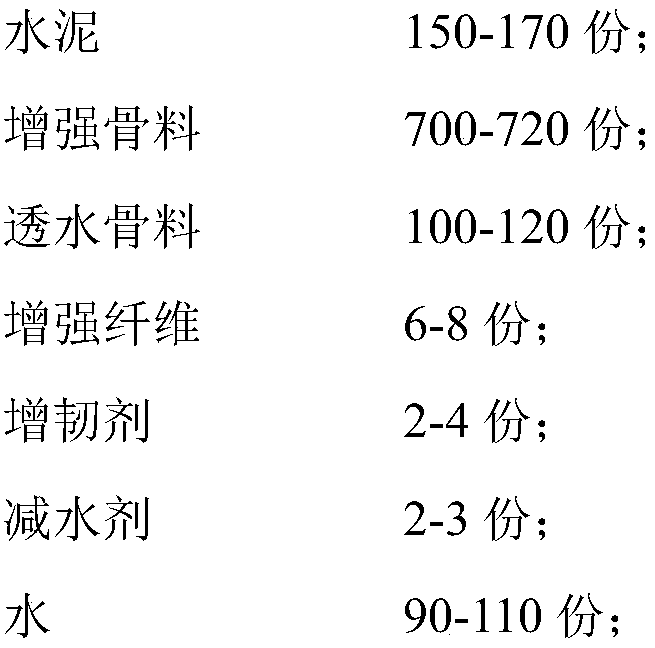

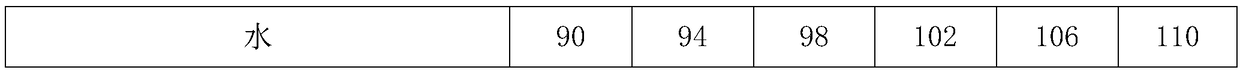

Method used

Image

Examples

preparation example 1

[0059] Preparation Example 1: Stir 0.5kg of benzoic acid, 1kg of ethylene glycol monobutyl ether, 2kg of sodium lignosulfonate and 2kg of sodium silicate at a speed of 400r / min, then add 2kg of redispersible latex powder, 6kg of high Molecular porous microspheres were stirred at a speed of 1000 r / min for 30 minutes at a temperature of 110° C. to obtain a toughening agent.

preparation example 2

[0060] Preparation example 2: Stir 0.8kg benzoic acid, 1.5kg ethylene glycol monobutyl ether, 2.5kg sodium lignosulfonate and 2.5kg sodium silicate at a speed of 500r / min, then add 2.5kg redispersible latex powder, 8 kg of polymer porous microspheres, and stirred at a speed of 1100 r / min for 25 min at a temperature of 115° C. to obtain a toughening agent.

preparation example 3

[0061] Preparation Example 3: Stir 1kg of benzoic acid, 2kg of ethylene glycol monobutyl ether, 3kg of sodium lignosulfonate and 3kg of sodium silicate evenly at a speed of 600r / min, then add 3kg of redispersible latex powder, 10kg of polymer Porous microspheres were stirred at a speed of 1200 r / min for 20 min at a temperature of 120° C. to obtain a toughening agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com