UV resin for four-arm astral symmetrical multi-block matte coating and preparation method of UV resin

A four-arm star-shaped and symmetrical technology, which is applied in the field of UV resin for four-arm star-shaped symmetrical multi-block matte coating and its preparation, can solve the problems of adverse production effects, influence coating effect, and difficulty in perfect mutual solubility, and achieve curing. Short time, stable matt effect, shorten production cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

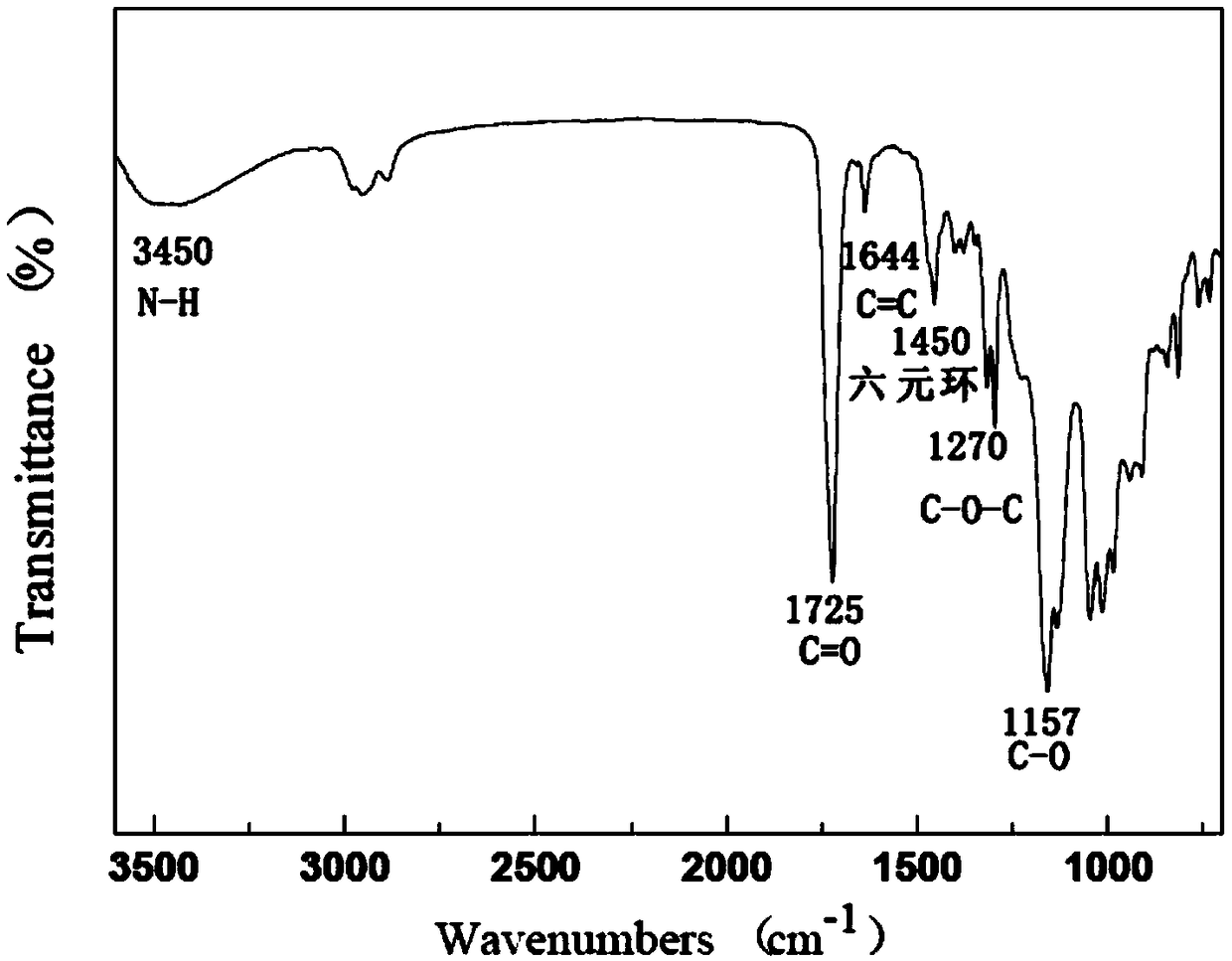

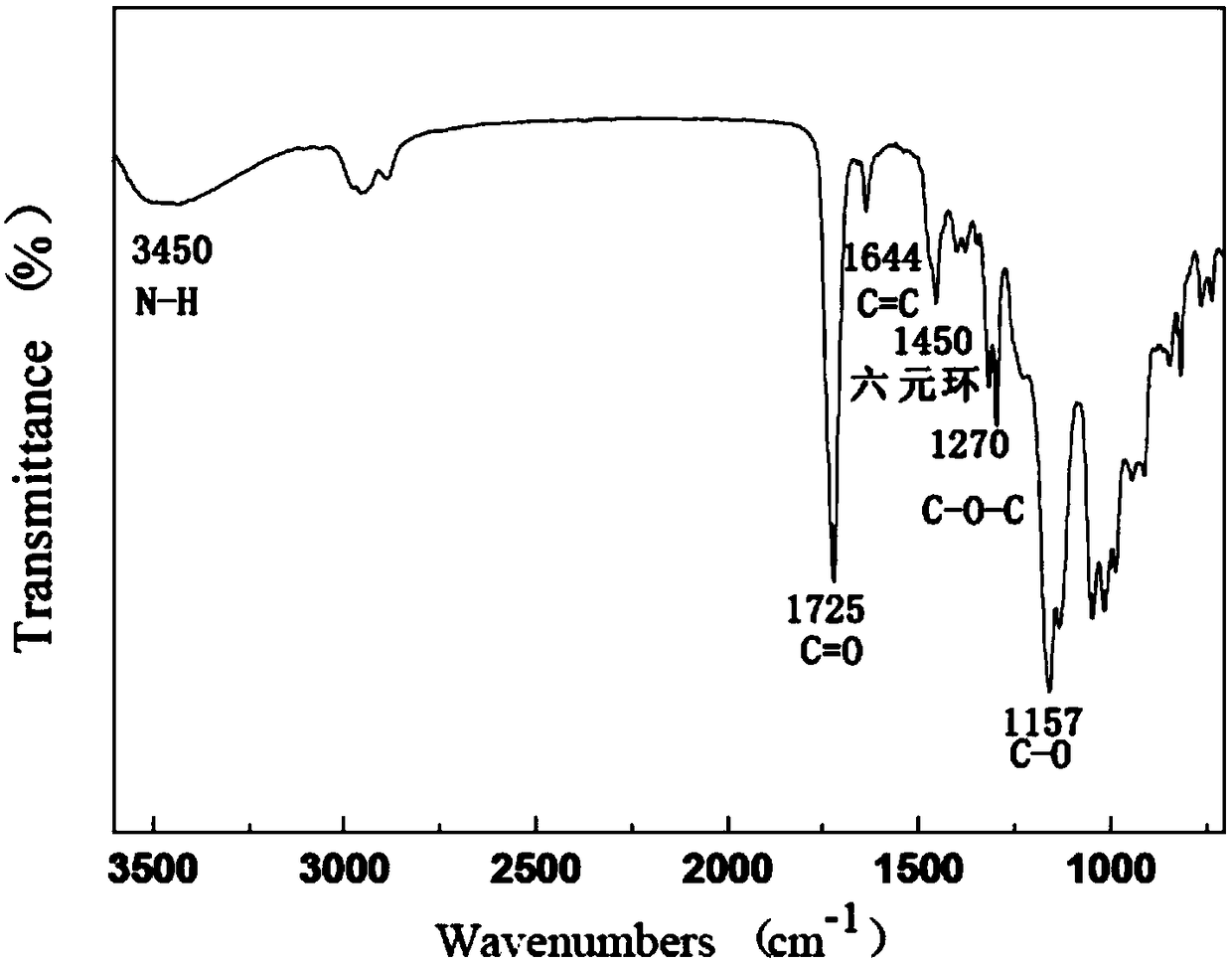

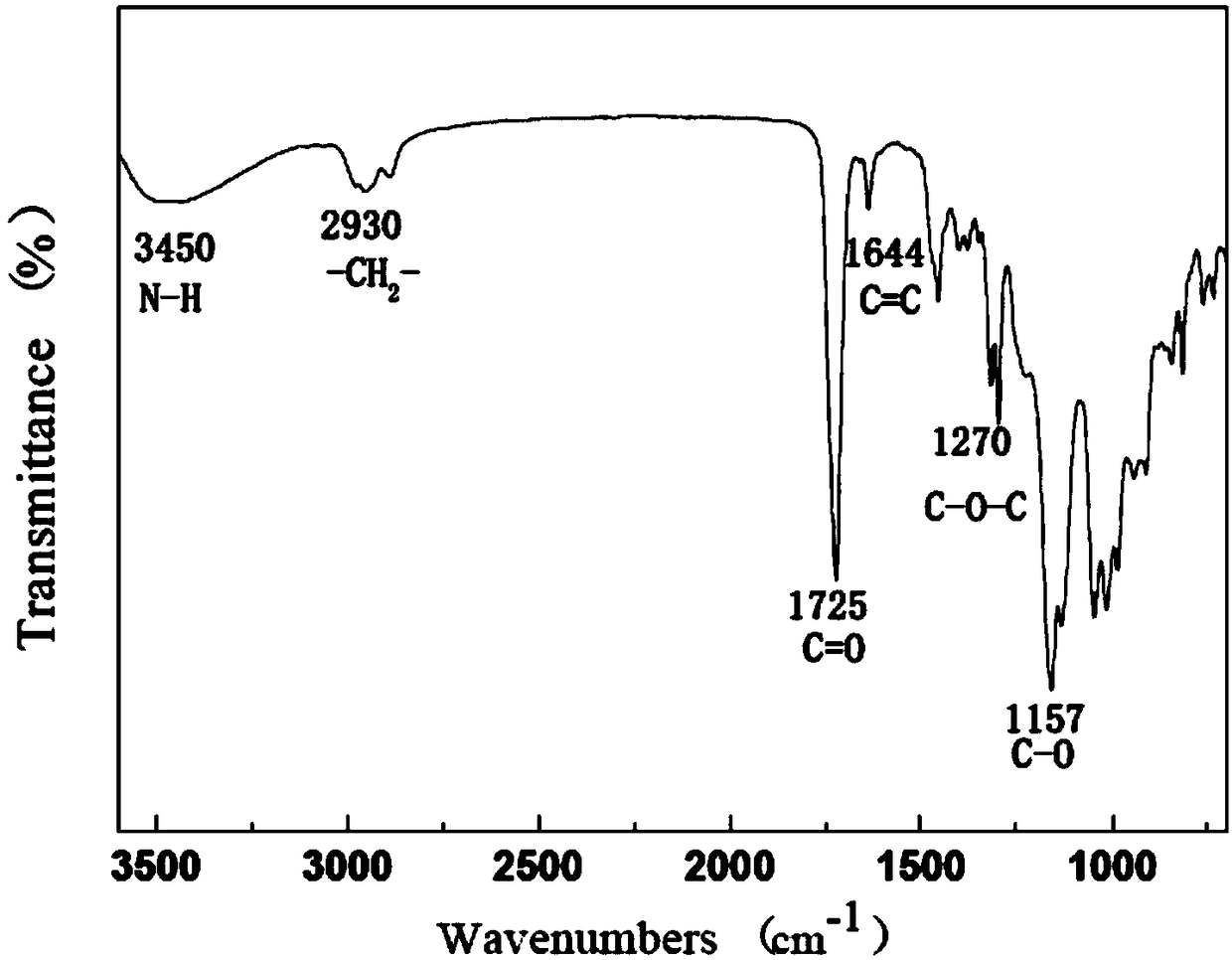

Image

Examples

Embodiment 1

[0043] Weigh 88.92g (0.4mol) of isophorone diisocyanate and place it in a reaction kettle, add 0.02g of catalyst dibutyltin dilaurate, heat to 50°C, and blow nitrogen. 46.45 g (0.4 mol) of hydroxyethyl acrylate was added, the addition time was 4 hours, and the reaction was incubated for 5 hours to obtain 135.37 g (0.4 mol) of isocyanate-terminated acrylate dimer.

[0044]Weigh 13.62g (0.1mol) of pentaerythritol and place it in a reaction kettle, add 0.013g of catalyst dibutyltin dilaurate, heat to 180°C, and blow nitrogen. Weigh 88.92 g (0.4 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 800 g (0.4 mol) of polyethylene glycol with a molecular weight of 2000 g / mol, and slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 4 hours. Adjust the temperature to 120°C, add 0.005g of catalyst dibutyltin dilaurate, and slowly add 135.37g (0....

Embodiment 2

[0047] Weigh 88.92g (0.4mol) of isophorone diisocyanate and place it in a reaction kettle, add 0.02g of catalyst dibutyltin dilaurate, heat to 35°C, and blow nitrogen. 52.05 g (0.4 mol) of hydroxyethyl methacrylate was added, the addition time was 6 hours, and the reaction was incubated for 2 hours to obtain 140.97 g (0.4 mol) of isocyanate-terminated acrylate dimer.

[0048] Weigh 13.62g (0.1mol) of pentaerythritol and place it in a reaction kettle, add 0.068g of catalyst dibutyltin dilaurate, heat to 180°C, and blow nitrogen. Weigh 88.92 g (0.4 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 5 hours, and the reaction is kept for 3 hours. Weigh 400 g (0.4 mol) of polyethylene glycol with a molecular weight of 1000 g / mol, slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 4 hours. Adjust the temperature to 120°C, add 0.005g of catalyst dibutyltin dilaurate, and slowly add 140.97g (0...

Embodiment 3

[0051] Weigh 88.92g (0.4mol) of isophorone diisocyanate and place it in a reaction kettle, add 0.44g of catalyst stannous octoate, heat to 90°C, and blow nitrogen. 58.03 g (0.4 mol) of hydroxypropyl methacrylate was added, the addition time was 2 hours, and the reaction was incubated for 5 hours to obtain 146.95 g (0.4 mol) of isocyanate-terminated acrylate dimer.

[0052] Weigh 13.62 g (0.1 mol) of pentaerythritol and place it in a reaction kettle, add 0.44 g of catalyst zinc naphthenate, heat to 230° C., and blow nitrogen. Weigh 88.92 g (0.4 mol) of isophorone diisocyanate and slowly add it into the reaction kettle, the feeding time is 6 hours, and the reaction is kept for 2 hours. Weigh 1200 g (0.4 mol) of polyethylene glycol with a molecular weight of 3000 g / mol, and slowly add it into the reaction kettle, the feeding time is 3 hours, and the reaction is kept for 4 hours. Adjust the temperature to 120°C, add 0.005g of catalyst dibutyltin dilaurate, and slowly add 146.95g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com