High-strength and anti-static polyphenylene sulfide and preparation method thereof

A polyphenylene sulfide and antistatic technology, which is applied in the field of high-strength antistatic polyphenylene sulfide and its preparation, can solve the problems of difficult dispersion of carbon black, affecting the service life of materials, affecting the strength of polyphenylene sulfide, etc., and achieves excellent performance. High strength, excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

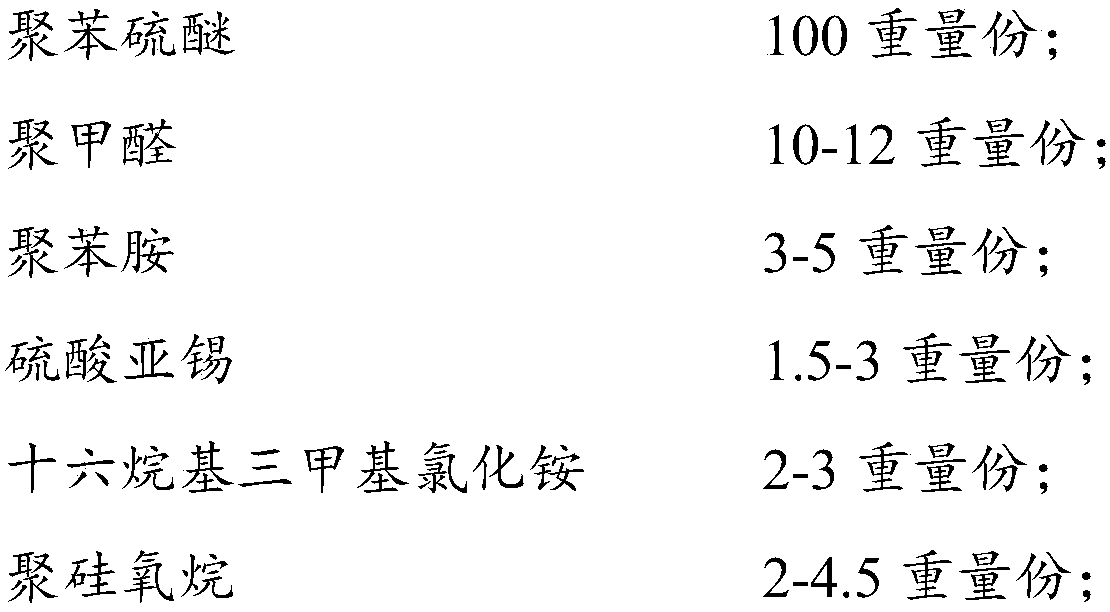

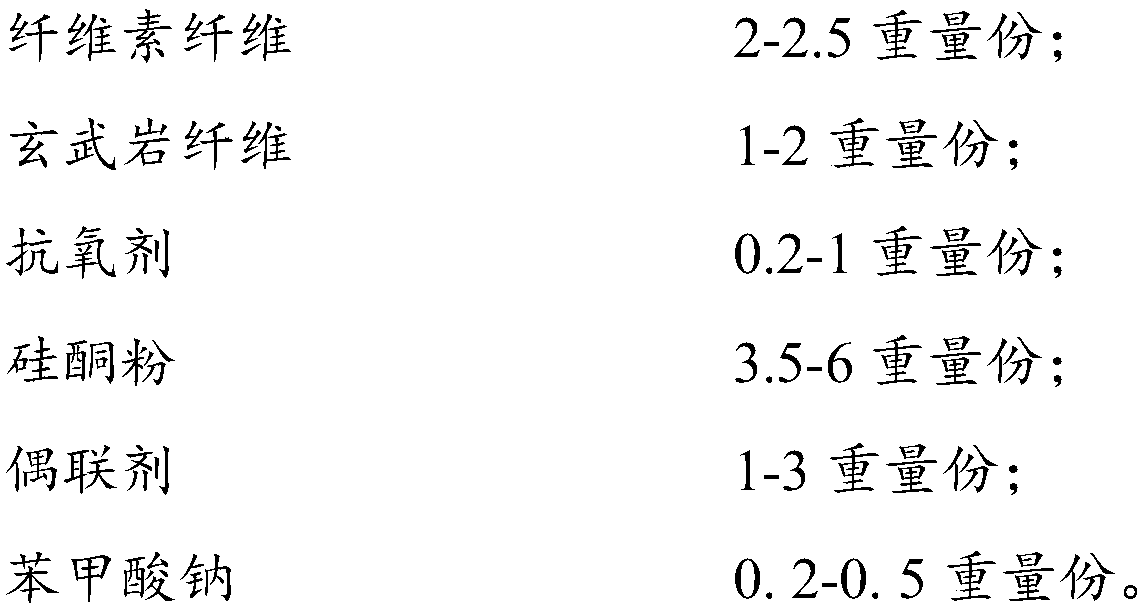

[0022] High-strength antistatic polyphenylene sulfide, composed of 100 parts by weight of polyphenylene sulfide, 10 parts by weight of polyoxymethylene, 3 parts by weight of polyaniline, 1.5 parts by weight of stannous sulfate, and 2 parts by weight of cetyltrimethylammonium chloride , 2 parts by weight of polysiloxane, 2 parts by weight of cotton fiber, 1 part by weight of basalt fiber, 0.5 parts by weight of antioxidant 1010, 4 parts by weight of silicone powder, 1 part by weight of coupling agent γ-aminopropyl triethoxy base silane and 0.2 parts by weight of sodium benzoate.

[0023] The preparation method of above-mentioned high-strength antistatic polyphenylene sulfide, the steps are as follows:

[0024] Step 1. According to the composition and ratio, polyphenylene sulfide, polyoxymethylene, polyaniline, stannous sulfate, cetyltrimethylammonium chloride, polysiloxane, cellulose fiber, basalt fiber, antioxidant Add the agent, silicone powder, coupling agent and sodium ben...

Embodiment 2

[0027] High-strength antistatic polyphenylene sulfide, composed of 100 parts by weight of polyphenylene sulfide, 11 parts by weight of polyoxymethylene, 4 parts by weight of polyaniline, 2 parts by weight of stannous sulfate, and 2.5 parts by weight of cetyltrimethylammonium chloride , 3 parts by weight of polysiloxane, 2 parts by weight of cotton fiber, 1.5 parts by weight of basalt fiber, 0.2 parts by weight of antioxidant 1010, 3.5 parts by weight of silicone powder, 1.5 parts by weight of coupling agent γ-aminopropyl triethoxy base silane and 0.4 parts by weight of sodium benzoate.

[0028] The preparation method of above-mentioned high-strength antistatic polyphenylene sulfide, the steps are as follows:

[0029] Step 1. According to the composition and ratio, polyphenylene sulfide, polyoxymethylene, polyaniline, stannous sulfate, cetyltrimethylammonium chloride, polysiloxane, cellulose fiber, basalt fiber, antioxidant Add the agent, silicone powder, coupling agent and so...

Embodiment 3

[0032] High-strength antistatic polyphenylene sulfide, composed of 100 parts by weight of polyphenylene sulfide, 12 parts by weight of polyoxymethylene, 5 parts by weight of polyaniline, 3 parts by weight of stannous sulfate, and 3 parts by weight of cetyltrimethylammonium chloride , 4.5 parts by weight of polysiloxane, 2.5 parts by weight of cotton fiber, 2 parts by weight of basalt fiber, 1 part by weight of antioxidant 1010, 6 parts by weight of silicone powder, 3 parts by weight of coupling agent γ-aminopropyl triethoxy base silane and 0.5 parts by weight of sodium benzoate.

[0033] The preparation method of above-mentioned high-strength antistatic polyphenylene sulfide, the steps are as follows:

[0034] Step 1. According to the composition and ratio, polyphenylene sulfide, polyoxymethylene, polyaniline, stannous sulfate, cetyltrimethylammonium chloride, polysiloxane, cellulose fiber, basalt fiber, antioxidant Add the agent, silicone powder, coupling agent and sodium be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com